Introduction

The life sciences industry has witnessed high growth in the past decade, driven by innovation of patent drugs and supportive government policies. However, decreasing R&D productivity and a spate of healthcare reforms have impacted profitability across the life sciences industry.

Given the changing market dynamics, life sciences companies are now faced with the challenges of financial liquidity due to extended timelines for bringing products to the market, tightening pricing regulations and a growing concern over protection of intellectual property. The business is becoming increasingly complex as more companies have diversified into related products as well as preempted the emerging markets. Each component of the supply chain — ranging from manufacturing to distribution — is vulnerable to all kinds of legal and regulatory risks.

As a result of weakened profitability and high risks, an increasing number of companies have shifted their focus from top-line growth to bottom-line savings. Therefore, it is imperative for procurement professionals to have an in-depth and profound evaluation of all categories of their spend.

This paper features strategies, case studies and valuable insights you can use to succeed in an increasingly challenging environment.

Unlocking Value

As life sciences companies struggle to sustain profits and maintain growth, the need to demonstrate economic value has become more magnified than ever. Life sciences companies are searching for novel ways to raise revenue and improve efficiency in all business areas. Apart from trying out innovative ways to increase turnover, they are also exploring new markets, product lines and sales channels.

However, one area that still promises to unlock significant value for the life sciences industry remains mostly untapped — procurement. Many managers in life sciences companies usually overlook the procurement function, even though it represents more than 50 percent of total costs and plays a key role in driving innovation, achieving marketing success, controlling risks and managing volatile supply markets.

Yet, life sciences procurement is a low-hanging fruit for cost savings and efficiency gains compared with other industries like automotive or retail, primarily because of the tremendous savings potential in indirect spend. Overall, procurement functions in life science companies traditionally outperform other industries in the area of direct spend control (raw materials, manufacturing), but only a few achieve excellence in controlling the much bigger indirect spending categories (IT, legal, marketing, facilities, office supplies, travel, etc.), which leaves nearly 50 percent of overall spend virtually unaddressed.

Most life sciences companies did not focus on savings opportunities in indirect spend until now, primarily because the cost pressure was not serious enough due to the rapid growth and higher profit margins in the past decade. In addition, unlike direct spend data, it is difficult to gather, align, and process complex indirect spend data from different systems and stakeholders. However, strengthening cost control, especially for indirect categories, has become extremely relevant now in wake of the changed market dynamics. Companies in the life sciences industry can no longer afford to ignore or miss cost reduction opportunities in indirect procurement.

Making Procurement a Competitive Advantage

To unlock savings opportunities from indirect spend, life sciences companies need improved control over their overall cost base and a greater ability to tap into underutilized resources. Establishing effective central governance and appropriate use of procurement outsourcing are effective strategies to control costs and risks.

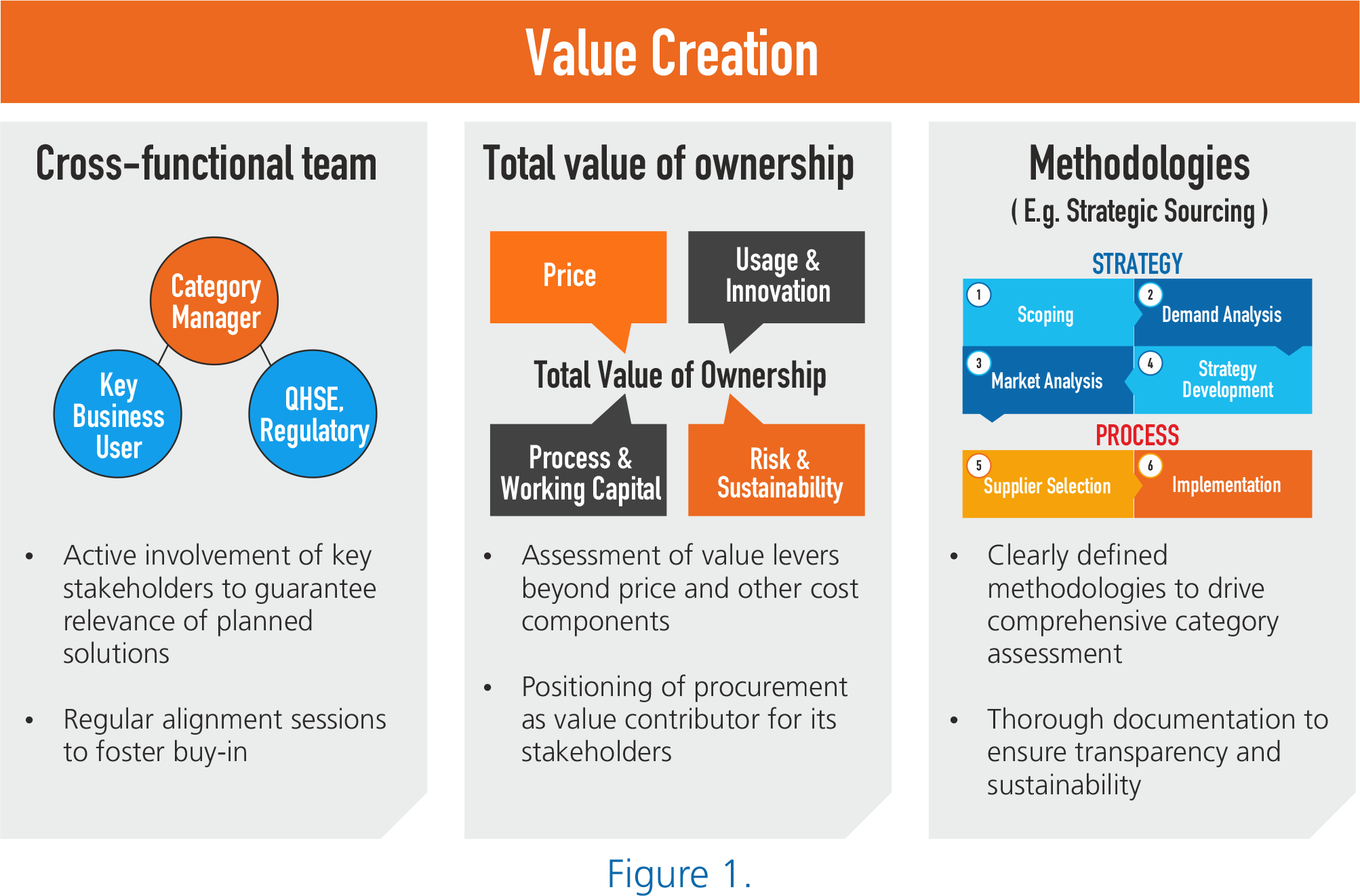

Indirect spending is largely untapped and significant in size among all categories of spend. However, reaping maximum benefits will require enterprises to look beyond the traditional negotiations, obvious panel consolidations and basic supplier relationship models. Companies need to explore the full set of purchasing and value sourcing levers, and build truly optimized outsourcing strategies and enhanced capabilities to manage these complex partnerships. The three pivotal points (as shown in Figure 1) need to be considered when setting and strengthening the procurement function in an organization:

- Cross-functional team: Enterprises must have a good cross-functional team comprising category managers, key business users and regulation experts. Key stakeholders need to be actively involved to ensure relevance of planned solutions. Regular alignment sessions need to be held to foster buy-in.

- Total value of ownership: Companies must consider the total value of ownership when sourcing any category. Value levers, apart from the price and other cost components, such as quality, service, assurance of supply, adherence to SLA levels and other factors, need to be taken into consideration when making the final decision. In this way, procurement can act as a value contributor for its stakeholders.

- Methodologies: It is important to have well-defined methodologies for strategic sourcing to drive comprehensive category assessment. Thorough documentation must be maintained to ensure transparency and sustainability.

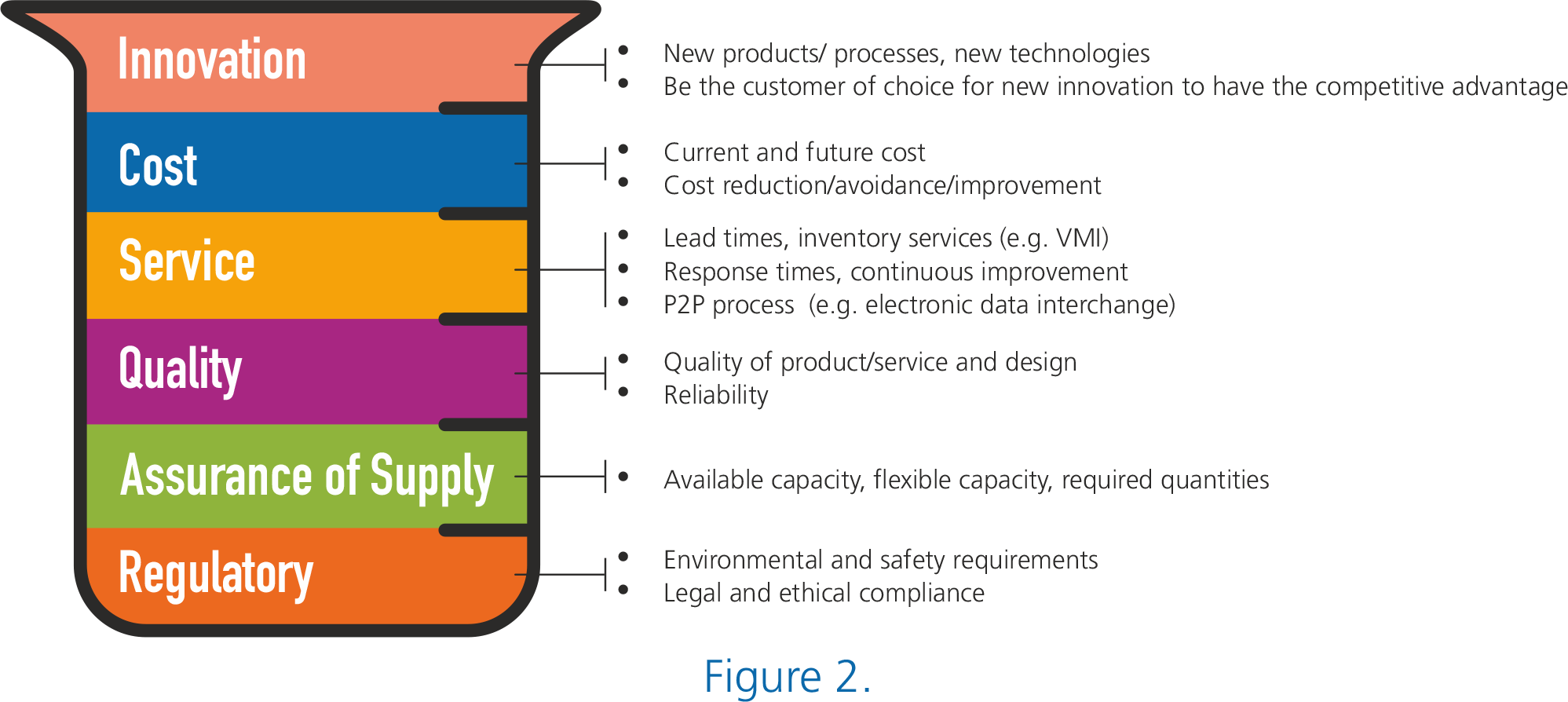

Procurement is not only about cutting cost; it's also about refocusing on tasks that add value. A sound procurement team focuses on all business requirements, not just cost (as shown in Figure 2).

Procurement can add value along several dimensions:

- Introduce a more competitive landscape to existing suppliers

- Negotiate tough issues with suppliers that are separate from the day-to-day interactions with business partners

- Provide market intelligence, industry trends, competitive analysis, performance benchmarking, automation, spend performance and visibility

- Cover contract management, coordination and validation of commercials with the legal team to ensure smooth transition to new suppliers

Challenges

Although a rigorous analysis of spend databases presents promising savings opportunities for the life sciences industry, it is also coupled with three main challenges that enterprises have to overcome: 1) silo barriers 2) complex indirect spend 3) global consolidation issues.

Challenge 1: Silo barriers reduce spend efficiency and transparency

Challenge 1: Silo barriers reduce spend efficiency and transparency

Silos are prevalent in every corner of an organization. While they are essential for operational efficiency and knowledge concentration, when it comes to procurement, they often act as barriers. Both direct and indirect categories are subject to the influence of silo effects. On the direct side, the procurement of production-related materials is highly decentralized to the manufacturing and engineering teams, with different specifications and buying patterns. Because much of the direct spend occurs in labs or plants, and is initiated by scientists or technicians who have little focus on controlling spend, the actual costs can far exceed the forecast.

A similar situation also applies to the indirect categories, some of which are perceived to be “protected areas” in the hands of subject matter experts, such as IT, telecom and legal. The procurement function has little say when manufacturing teams request the latest technologies to deliver cutting-edge products. The nature of scattered spend as well as the weak power of procurement functions make it hard to rationalize business demand and execute global strategy in complex and fragmented environments of biopharmaceutical companies.

Challenge 2: Cost-saving potential of indirect categories is huge but complex

Challenge 2: Cost-saving potential of indirect categories is huge but complex

Cost-saving opportunities thrive in the spend database, especially the indirect categories. Unlike direct categories that are often required to reconcile manufacturing constraints and stringent quality control, indirect categories are relatively free from these hurdles. However, as indirect costs are not as relevant as cost of goods sold (COGS) to the core business, companies tend to pay less attention to them in the daily business. What adds to the challenge is that the indirect spend data originates from a multitude of systems owned by various stakeholders, making it difficult to gather, align and process.

In addition, there are various other factors that contribute to the complexity. For example, office supplies remain uncovered because the stakes are too low to spend efforts in review and analysis. In contrast, marketing spend is often considered “off limits” by top management since it is directly linked to business growth. The focus of such a category is not to minimize spending, but to boost return on investment. The vast difference among sub-categories under indirect spend leads to lack of emphasis on a strategic level within the organization.

Challenge 3: Fast global expansion causes cost spikes

Challenge 3: Fast global expansion causes cost spikes

As life sciences companies expand to emerging markets, the demand for seamless collaboration among various country offices and outsourced organizations becomes unprecedentedly important — so does the need for well-coordinated procurement spending. Without a systematic plan and strong control over spending, the costs can easily escalate in a bid to cover the much wider geographical footprint due to multiplication of suppliers in different locations. Therefore, it is necessary to coordinate resources and improve efficiency of spend with cross-regional collaboration, either by combining spend on common SKUs or trimming the list of suppliers — ranging from niche-oriented to fully integrated ones.

Some Common Issues & Remedial Strategies

Issue: Historically, life sciences has been a high-margin industry. However, the last few years have seen a decrease in profit margins. While procurement had traditionally been focusing on service and meeting growth requirements, the focus has now shifted toward reducing costs and driving more value from suppliers.

Strategy: Introduce preferred supplier programs whenever possible. This funnels business to a few, high-value suppliers, allowing companies to realize gains from increased volume and lower costs, as well as push the suppliers to increase value and quality.

Issue: Historical focus on new product introduction has resulted in large tails of lowspend suppliers.

Strategy: Consolidate suppliers whenever possible to minimize tail-spend and inform buyers of key vendor relationships.

Issue: Historical focus on direct versus indirect spend

Strategy: Shift focus to address high-spend indirect areas.

Issue: As is inherent in this industry, many suppliers provide specific molecules/IP and proprietary technology. This results in fewer suppliers who can be used as substitutes.

Strategy: Work on improving the relationships with existing suppliers. Develop partnerships to mutually work through any quality or service issues and be prepared for a vendor switch if it appears remotely necessary.

Issue: Overlap of suppliers and customers (customers who are also competitors)

Strategy: Devote more attention to supplier relationship management to ensure an amicable relationship that is mutually beneficial to both parties.

The GEP Way to Deliver Savings

Execution is the key to realize cost savings from a complex spend database. GEP engages various stakeholders to break down the silos and encourage cross-functional collaborations over spend. This section will outline key strategies from GEP’s recent experiences in helping multinational life sciences companies with various categories of spend, such as legal, marketing print and cafeteria services.

Case 1: R&D Procurement versus Corporate Procurement and inefficient purchasing processes of lab equipment

Approach: Manage purchasing practices and communication

In many life sciences companies, there are separate procurement groups for R&D services and corporate services/direct goods. Generally, the R&D team places less focus on optimizing cost and more emphasis on buying the right tools and lab equipment when needed. Often, there's little communication and cooperation between the two entities, leading to ineffective purchasing. This was the case at a U.S.-based life sciences company, where R&D procurement faced less stringent purchasing processes, allowing lab technicians to buy equipment as needed through unrestricted avenues.

The GEP team understood the inefficiencies of such procedures and recommended/led a joint task force comprising members from both procurement teams to identify a solution. Together, through detailed RFPs and supplier qualifications, a list of approved vendors was developed. A process was also put in place that all buyers had to follow when requesting a purchase. The end result was an agreement with five preferred vendors, allowing volumes to be channeled to a small list of providers, maximizing purchasing power and supplier control, while also ensuring lab technicians received the necessary instruments in a timely fashion.

Case 2: Supplier base consolidation for marketing prints

Approach: Consolidate supplier base to leverage economies of scale and partnership

For large global brands, consistency among marketing print vendors is a key point of concern — from managing brand colors across printers to finding creative promotional goods that set them apart from competitors. A fast-growing global life sciences company was struggling to manage standards and pricing of marketing print and promotional items across its various country offices. An increasing number of business units were independently selecting their own print and promotional items suppliers, making it difficult to leverage economies of scale and oversee the total spending.

GEP helped the company to consolidate its suppliers by evaluating all incumbent and prospective suppliers and confirming service level agreements (SLAs) which highlighted fast turnaround time, mature storefront, order tracking, high quality samples and cost management programs. The bidding process helped screen vendors by size, global presence and warehouse capabilities, as well as allowed the selection of a single partner to manage marketing print and promotional needs. The engagement ended up with 30 percent cost savings and high-quality services in compliance with the SLA.

Case 3: Switching payment model to turn cafeteria services into a win-win situation

Approach: Create innovative payment methods that reward good performance and results

To increase health and wellness options for employees, a U.S.-based life sciences company asked GEP to help identify a cafeteria and catering service provider for all sites in the United States. After estimating the size of demand, GEP consultants decided to switch from a management fee model to a profit/loss account. In this “zero-subsidy” model, all profit or loss accrued to the operator.

In addition, the team also moved away from a cafeteria-like setup to an aesthetically pleasing, gourmet experience with increased focus on healthy, fresh and flavorful options. The model not only generated significant savings, but also motivated the cafeteria operator to strive for customer satisfaction.

Conclusion

Undoubtedly, life science is one of the fastest-growing industries in the world and will continue to do well in the near future. However, diminishing R&D productivity, healthcare regulations and increasing global competition will continue to put margins under pressure. To ensure sustainable growth, life sciences companies will have to look toward procurement as a more strategic partner in all areas of direct as well as indirect spend.

By having full control and visibility of every type of spend — using the approach, process and tools mentioned in this paper — life sciences companies can unlock significant value through procurement and remain competitive even in challenging market conditions.