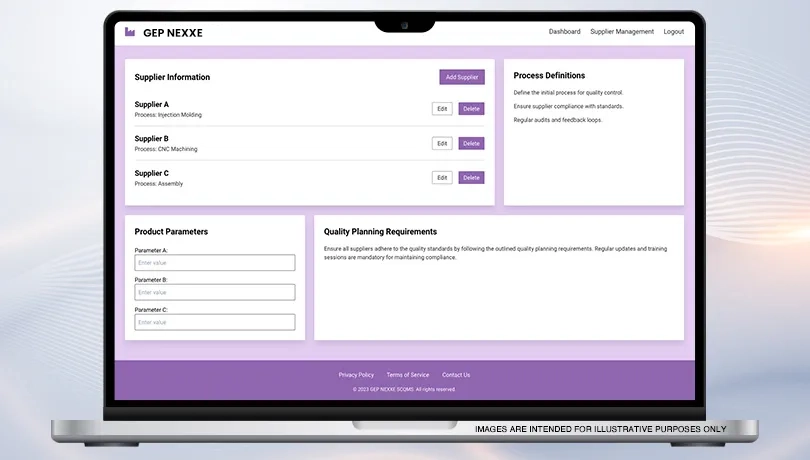

In today’s fast-paced business environment, frequent changes to products and processes demand adaptable and responsive quality systems. GEP NEXXE™ Supply Chain Quality Management System (SCQMS) simplifies managing product quality planning with suppliers by defining processes and product parameters.

Our supply chain software is built on a low-code platform for seamless integration and features configurable workflows, intelligent forms and an intuitive interface for supplier collaboration. Track quality conformance, address exceptions and stay ahead of potential issues.

Quality Management Service Allows Suppliers to Collaborate in Real Time

Powered by GEP MINERVA™, GEP NEXXE Supply Chain Quality Management Solution is supply chain software driven by AI and machine learning. Built on a low-code platform for seamless integration, it features configurable workflows and intelligent forms to meet quality objectives. The intuitive interface ensures real-time collaboration with suppliers.

Quality Planning

Manage quality plans, quality project (APQP/PPAP/Part Qualification) and inspection plans at the material/material group level — so that you can always meet product expectations.

Quality Operations Management

Handle day-to-day transactions, such as inspection lots, quality events or deviations with total ease and control. Assign actions, such as tasks and CAPAs to suppliers, based on quality findings.

Audit Management

Audit your suppliers for quality. Track key metrics on quality via systematic assessment of quality scores — to ensure total compliance.

Document Management / Approval Workflows

Track, review and manage all quality documents with customer feedback effectively.

Third-Party Integration

GEP NEXXE SCM QMS seamlessly integrates with all major ERP systems to retrieve, synchronize and manage master data.

Resolve Exceptions

Resolve exceptions through feedback management and CAPA workflows. Stay ahead of every quality control issue during operations.

EXPLORE OUR FULL RANGE OF FUNCTIONS

Why Choose GEP NEXXE Quality Management System Software

- Achieve Operational Consistency: Streamline processes for efficiency.

- Reduce Time-To-Market: Integrate PLM for faster product launches.

- Resolve Issues Faster: Comprehensive audit management for efficient problem-solving.

- Eliminate Kickbacks: Identify root causes and resolve issues proactively.

- Easy Document Control: Manage documents for evidence-based decisions.

- Ensure QMS Compliance: Stay compliant with global standards.

FAQ

A quality management system, or QMS, establishes a set of process definitions and product parameters so enterprises can easily manage and share product quality planning requirements with suppliers. Also known as a supply chain quality management system, or SCQMS, the set of processes include configurable workflows and intelligent forms to ensure efficient part qualification.

Unlike legacy systems, advanced quality management systems are adaptable and can take corrective actions on demand. A QMS helps enterprises track product quality conformance and anticipate quality control issues. Enterprises can also use resolve exceptions through feedback management and corrective and preventive action (CAPA) workflows.