More than half of leading global enterprises do not have an effective supplier relationship management (SRM) program in place, studies say.

Why do so many otherwise successful organizations founder on SRM? How can your team avoid the same fate?

In this white paper, Epic Fail: 5 Proven Ways to Botch Your Supplier Relationship Management Program, GEP looks at five key reasons why many enterprise SRM initiatives fizzle out or fade into ignominy.

It doesn’t have to be that way. This paper provides useful strategies to overcome each challenge and succeed where so many others have failed.

What’s Inside:

- How to build an SRM program aligned with the wider business strategy

- Strategies to create higher value through Supplier Relationship Management (SRM)

- Tracking and measuring the performance of your initiatives

Read today for insights into how to avoid pitfalls and build enduring partnerships with your vendors.

INTRODUCTION

Supplier Relationship Management (SRM) is not a new concept, but it has been growing in importance. The theory is that SRM helps enterprises drive value in both recessionary periods – by enabling cost reductions, and also in high growth phases by supporting increases in market share. The reality, however, is that very few organizations have seen demonstrable results from SRM programs — very few of these initiatives are truly effective or sustainable, primarily due to poor strategy and execution.

The overall trend of the increasing scale of outsourcing over the last decade and the extension in the capability of many global outsourcers have led to a pool of critical outsourcing suppliers who wield significant control over an organization’s upstream supply chain. These outsourcers are a genuine source of enhanced capability for their clients. With this dynamic, it is imperative for businesses to work with their supplier base to gain and maintain a competitive edge. This can best be achieved through more collaborative ways of working between the traditional buyer and supplier.

There’s a need for a paradigm shift from the traditional business practice of adopting an adversarial approach toward the supply base, especially when it comes to dealing with key strategic suppliers. Traditionally, procurement functions have been fixated on cost reductions in their dealings with suppliers, in many cases at the cost of better overall value — an approach which has strained relationships with the supply base as well as internal business stakeholders. An alternative, or ideally complementary approach, is building strong relationships with critical elements of the supply base through a comprehensive SRM program and leveraging these relationships for driving genuine and significant business value.

This paper discusses the challenges in executing a successful SRM program and provides strategies for procurement executives to drive more value through effective SRM initiatives.

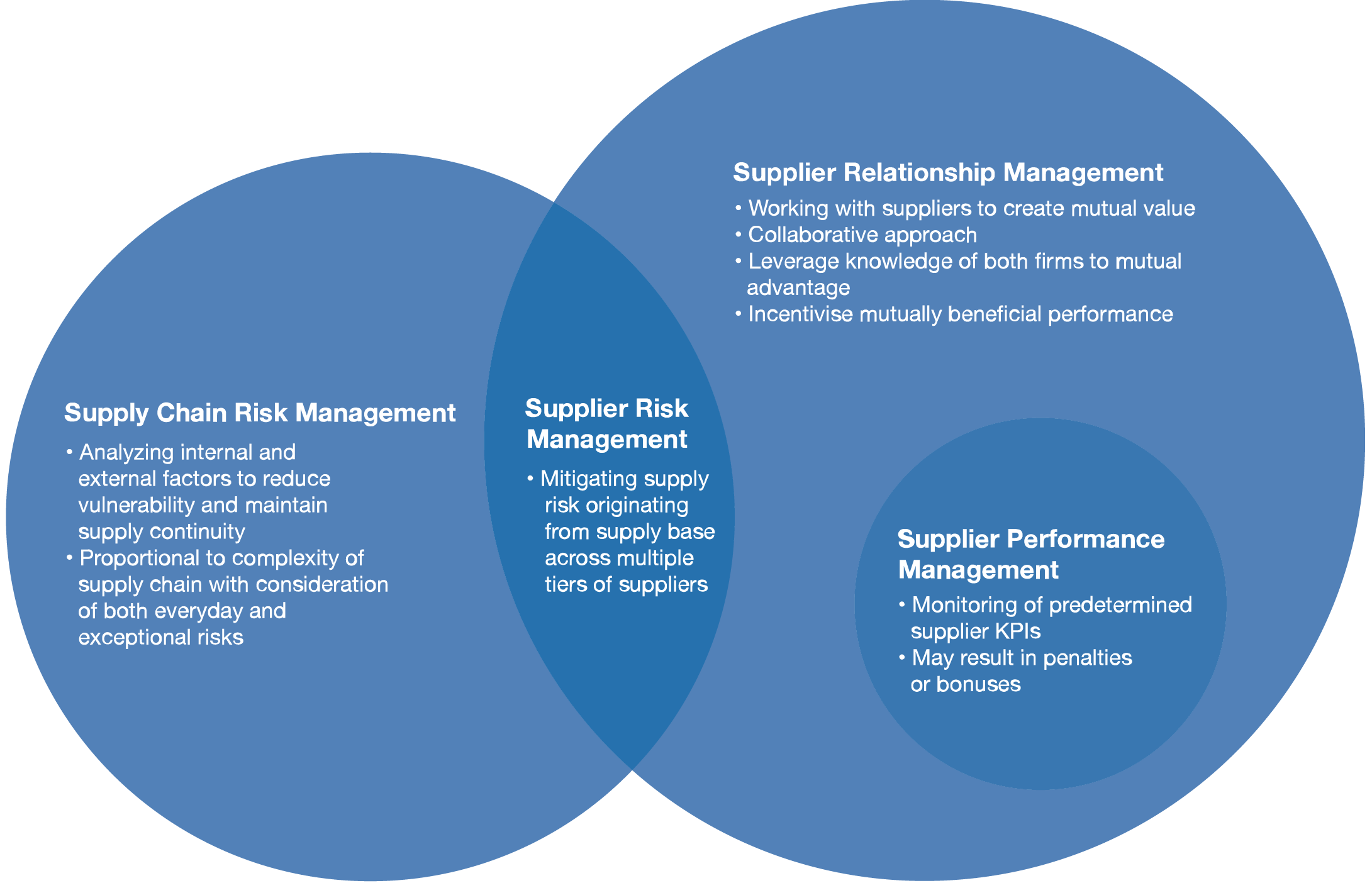

WHAT IS SRM?

Supplier Relationship Management (SRM) is the discipline of strategically planning and systematically managing interactions with select third-party suppliers to maximize the value of those interactions over the relationship life cycle.

Fig 1. Understanding SRM and Supplier-Related Initiatives

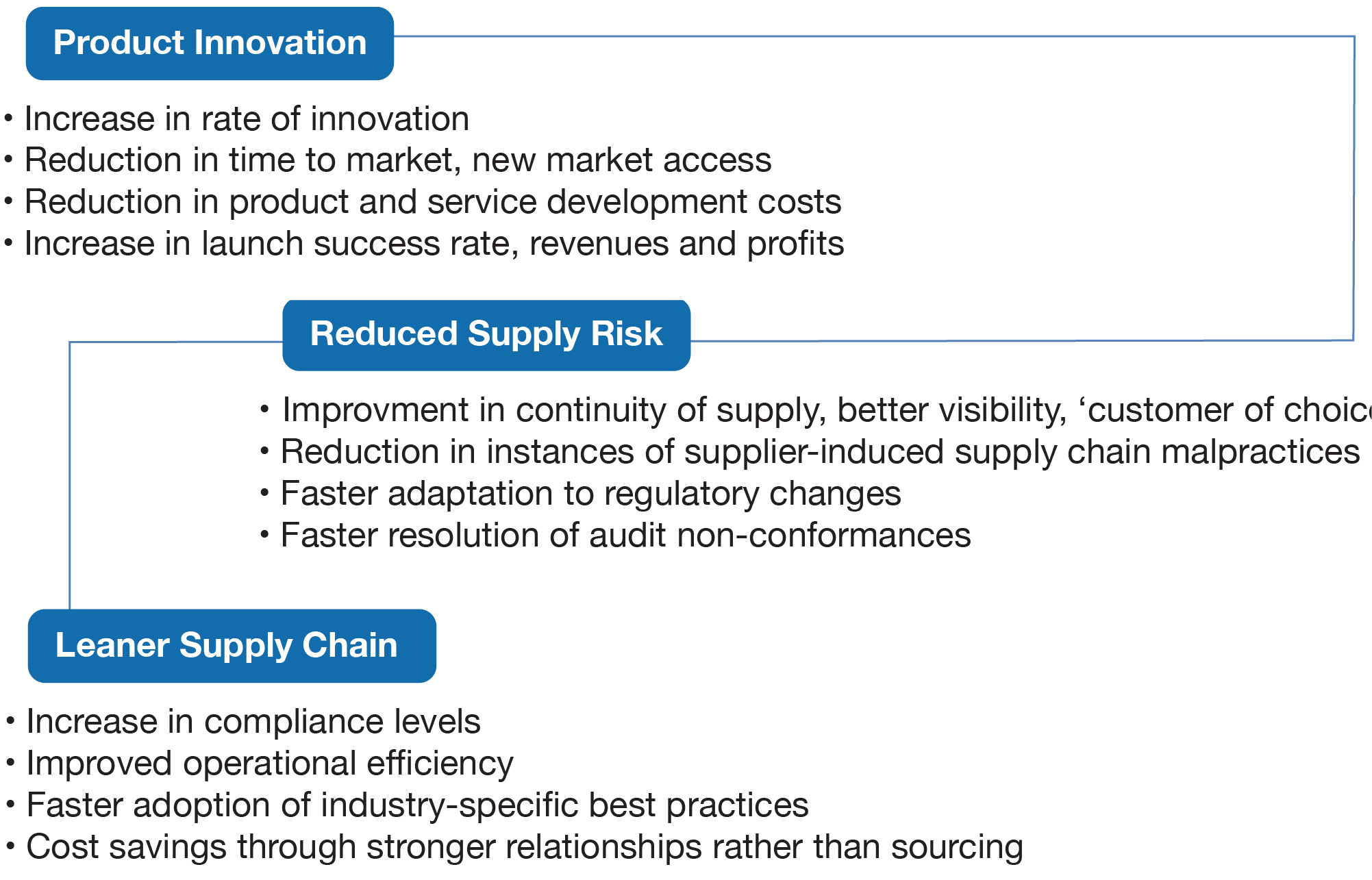

SRM has gained popularity within many corporate circles, but very few organizations have managed to realize its full potential. Companies are lured by the benefits of SRM, such as supplier-led innovation, risk management and improvement in operational efficiency, and are quick to jump on the bandwagon with expectations of instant payoff.

In reality, SRM is a relatively long-term process that requires a cross-functional and coordinated approach, a robust governance structure, and innovative methodologies to track and measure value. Many organizations fail to measure the benefits from SRM initiatives objectively, resulting in the program getting abandoned midway or dragging on unfulfilled on the procurement agenda — without any gain and sign of real benefits — inevitably impacting investment and business focus.

It is not uncommon to find organizations that have an SRM structure in place, but, behind the curtain, the team either will be resorting to the age-old tactic of arm-twisting suppliers for cost reductions or will be responsible for supplier performance management programs (SPM). Such conditions have led organizations and people to grow cynical about the true benefits of SRM. However there are significant and sustainable benefits that enterprises can drive through an effective SRM program.

Fig 2. Key Benefits of an Effective SRM Program (industry agnostic)

SO WHAT’S STOPPING ENTERPRISES FROM ACHIEVING THE TRUE POTENTIAL OF SRM PROGRAMS

Challenge 1: Misalignment between SRM Strategy and Business Strategy

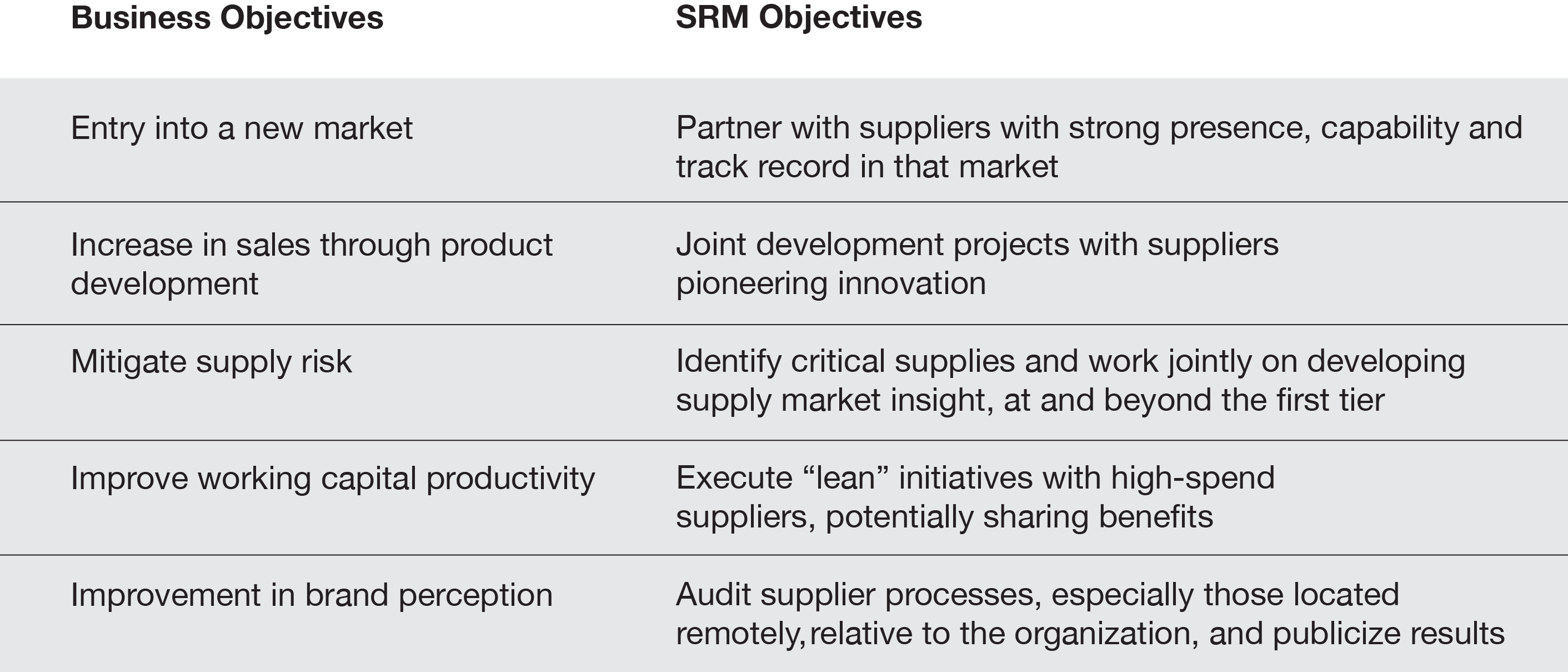

One of the primary factors hindering the success of SRM programs is the misalignment of SRM strategy with the overall procurement strategy and the wider business strategy — notably, the strategies of business stakeholders that procurement executives want and need to contribute to the SRM program to make it scalable and more effective. This misalignment leads to needless expenditure of resources on an initiative that may not be inresonance with the long-term business objectives of the enterprise, leading to deprioritization of the SRM program on the procurement agenda.

The best approach for ensuring alignment is to translate business strategy into SRM objectives. For example, if the wider business strategy is to expand business in emerging markets, then an SRM objective could be to identify suppliers from the existing base who have a strong presence in the target emerging markets. Enterprises can use the support of their suppliers to develop business in these new markets, using their market knowledge through joint marketing, joint ventures, or other strategies.

Building a business ROI case around such initiatives that outlines the investments in terms of resources and estimates the value of expected outcomes can help gain the much-needed attention and sponsorship of senior management, and bring about a behavioral change in the organization toward the concept of working jointly with key suppliers.

Fig 3. How SRM Can Support Business Objectives

Challenge 2: Lack of Cross-Functional Collaboration & Robust Governance

Many organizations believe SRM to be a procurement-specific program, whereas, to be effective, it must be a procurement-led program requiring engagement and participation from stakeholders across the enterprise. It is common to come across instances of negotiations with suppliers on an SRM initiative falling through in the last stage due to lack of inter-department communication and coordination. For such initiatives to be successful, the requirement is to build a cross-functional working team consisting of direct stakeholders. Procurement should use its crossfunctional interactions, data and team to coordinate and drive the initiative.

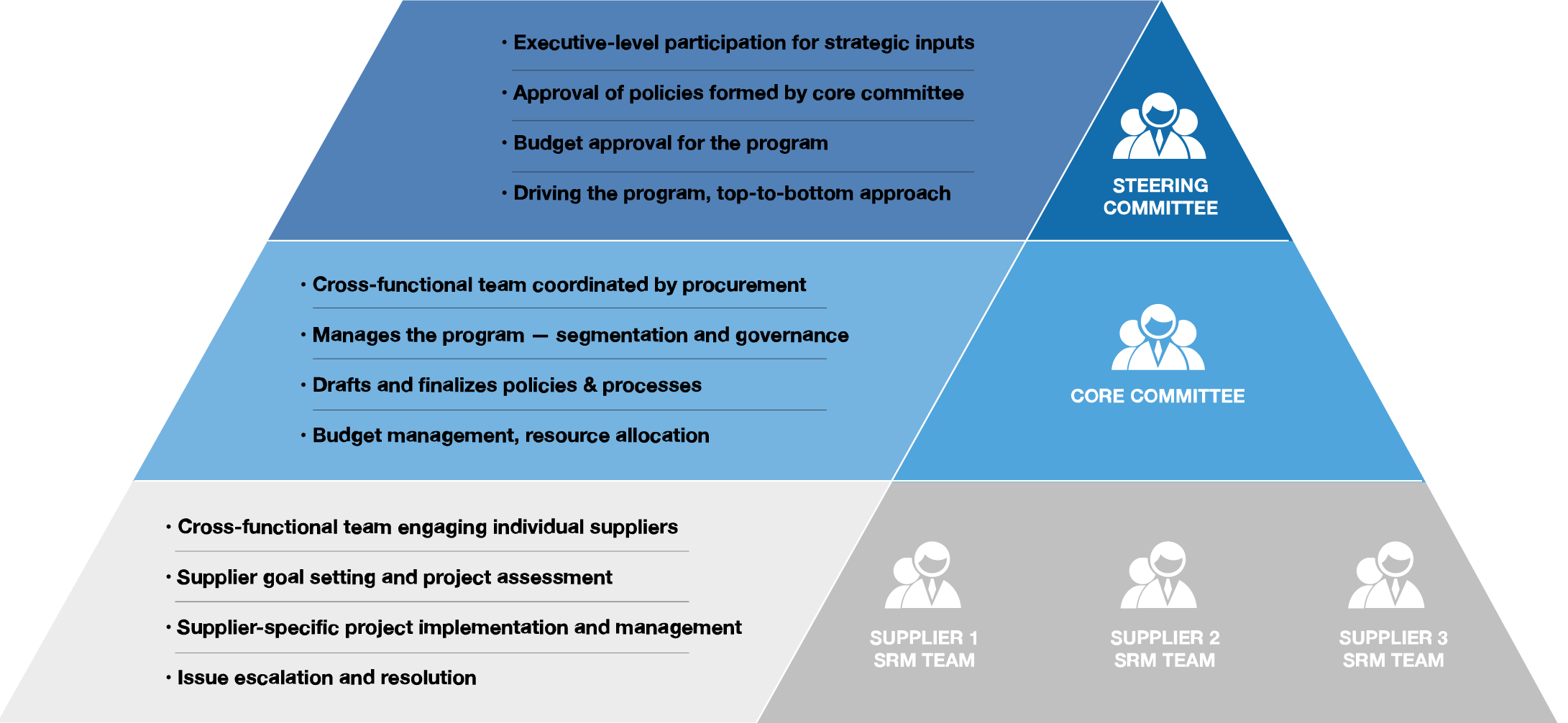

The cross-functional team will be responsible for end-to-end execution of the supplier-specific initiative. As there will be numerous independent initiatives within an organization — each relating to different suppliers, driven by different teams — a core committee driven by procurement and consisting of SRM champions nominated from the relevant functions should be established to drive coordination and oversee the program. To ensure alignment between the initiatives and the wider business strategy, a steering committee consisting of senior executives should be involved to provide timely strategic direction to the program.

Fig 4. SRM Governance Structure

With the team structure in place, the next step is ensuring smooth and streamlined execution. The primary challenge in achieving this is that SRM initiatives within the same program tend to differ in goals and timelines. For example, one initiative may be to work with a supplier in a joint process improvement program to be executed over a year, whereas another initiative could be to work with a supplier on service quality improvements to be executed over a quarter. Both the initiatives will involve different process steps and timelines, making it difficult to adopt one-size-fits-all approach to specific program management.

However, all of these different initiatives cannot be left to run independently as this will lead to a lack of coordination,prioritization, and reported results, all of which are essential for continued investment.

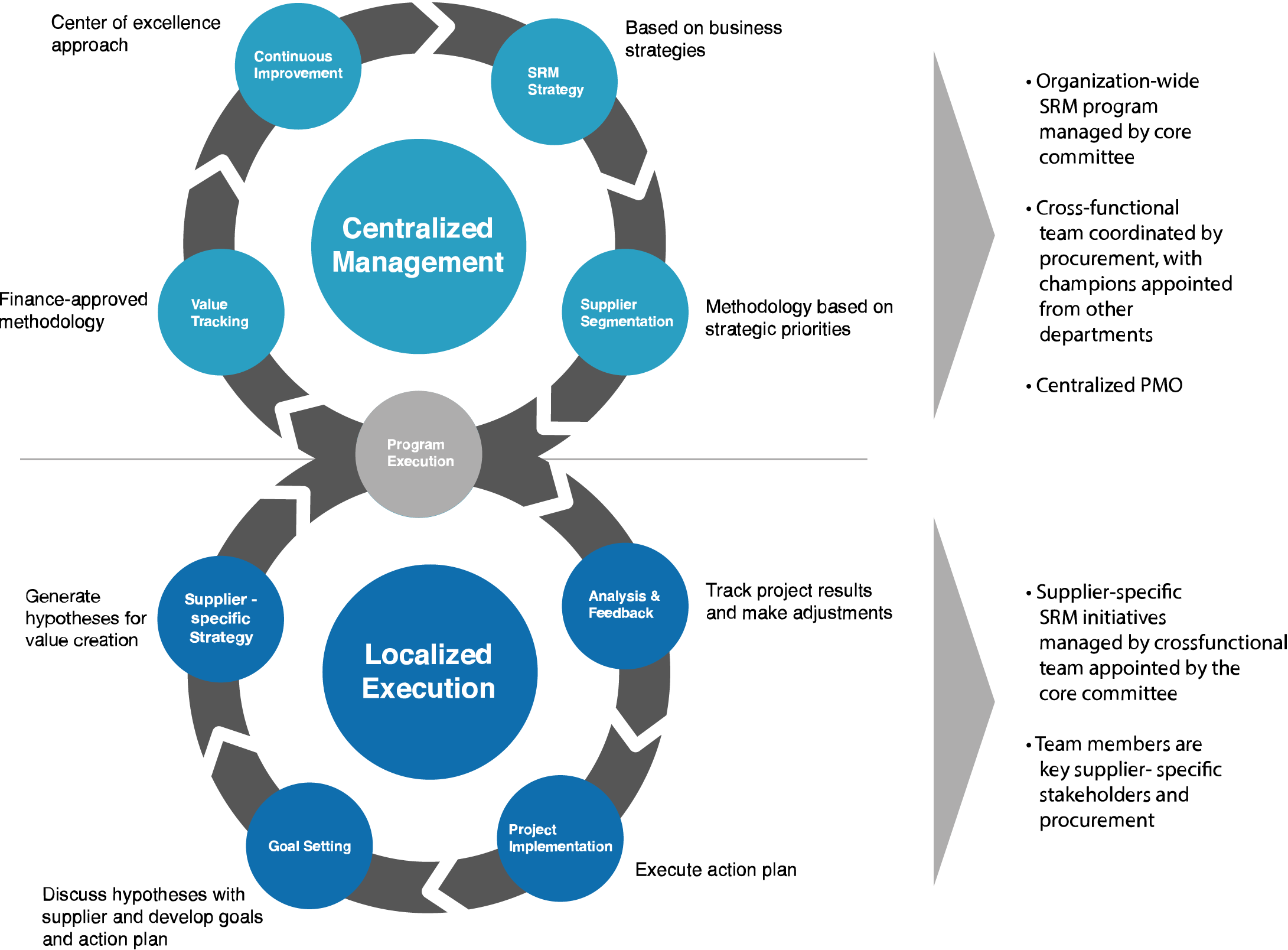

Centralized management and localized execution is the approach to adopt for execution of the overall SRM program. The core committee will be responsible for overseeing the program execution and handling the overall program management, whereas, the localized cross-functional team will be responsible for the supplier-specific initiative.

Fig 5. Centralized Management, Localized Execution

Challenge 3: Lack of Effective Supplier Segmentation and Supplier-Specific

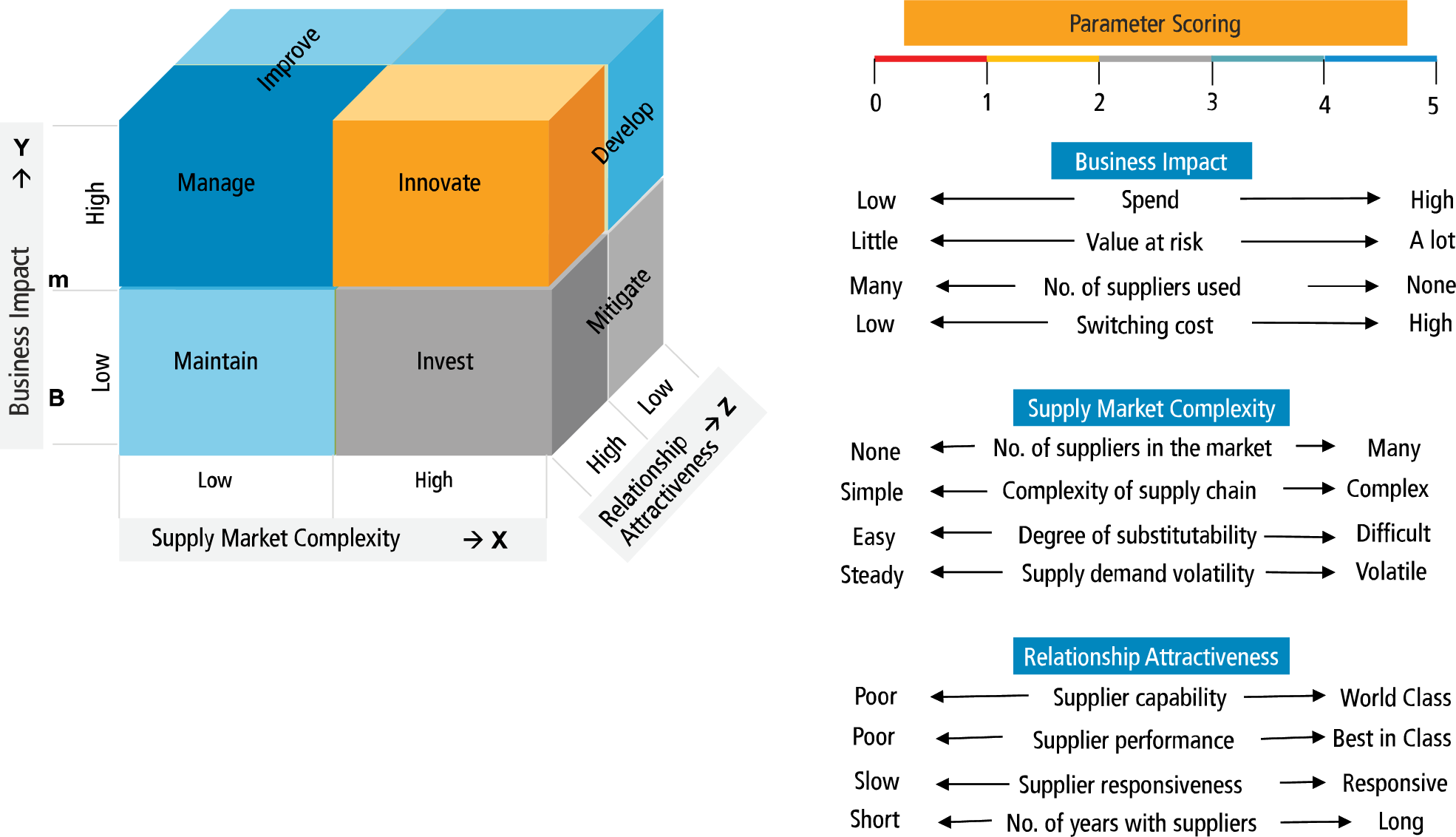

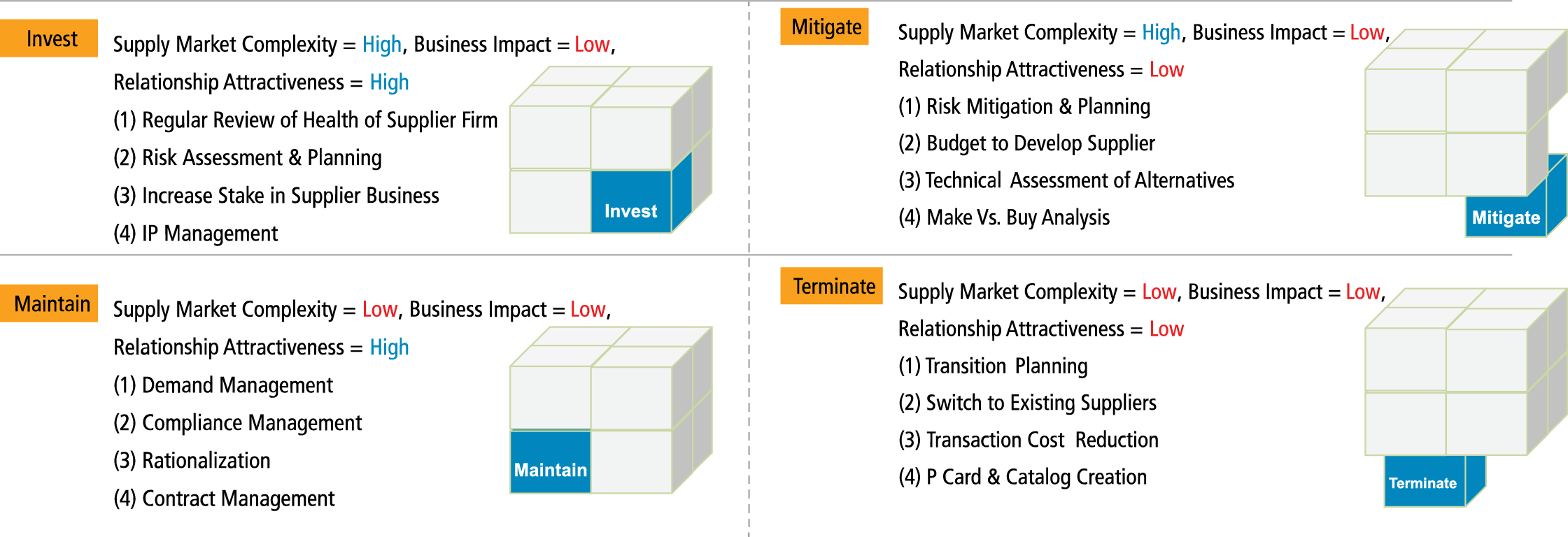

Enterprises typically segment their suppliers on the basis of two parameters: business impact and supply market complexity — this is often driven by procurement’s obsession with a 2x2 Kraljic matrix approach to any question. Based on these two parameters, the suppliers are conventionally classified into following categories: strategic, bottleneck, leverage and routine suppliers. However, this standard procurement segmentation is not sufficient for effective SRM and often leads to execution errors and poor ROI. By incorporating a third parameter which measures the long-term compatibility between the organization and supplier, the segmentation can be further enriched and optimized for a strategic SRM program.

Figure 6 is the GEP SRM Cube used for effective segmentation of suppliers for SRM. By taking a weighted average of the different sub-parameters organizations can design their own scoring methodology for supplier segmentation.

Fig 6. GEP SRM Cube© Segmentation (High-Level Summary)

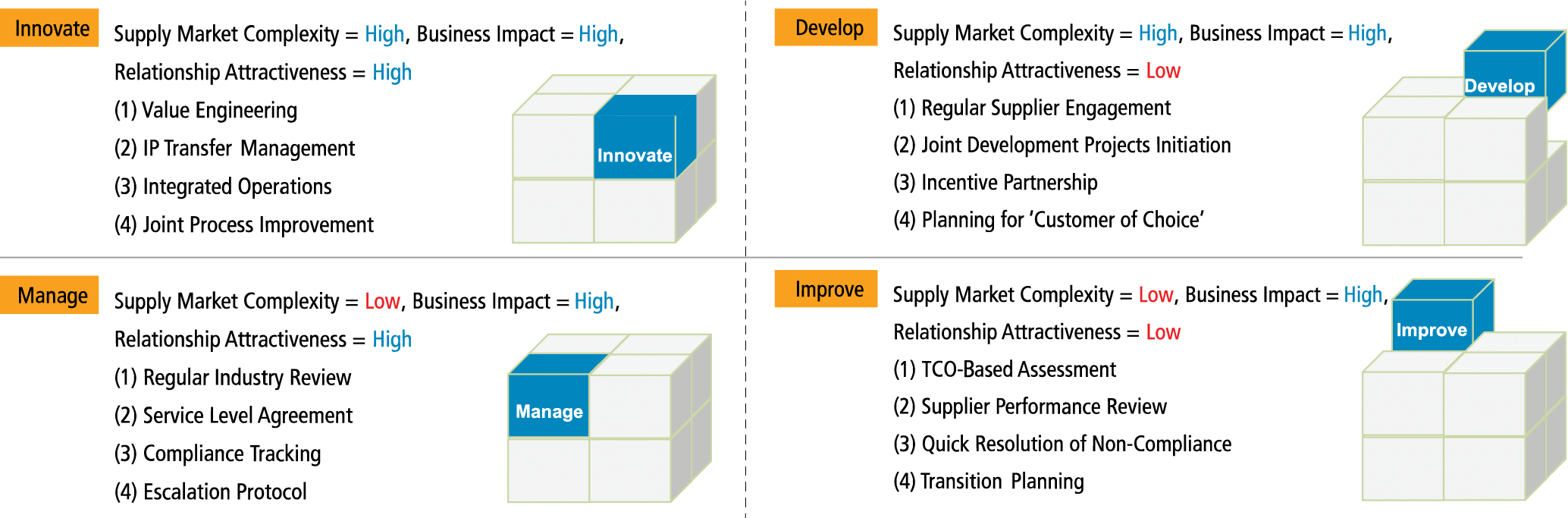

Each segment of suppliers has certain characteristics, and based on the segment to which a supplier belongs,different strategies should be formulated to generate mutual value for the organization and suppliers

Fig 7. GEP SRM Cube Supplier Strategies (High-Level Summary)

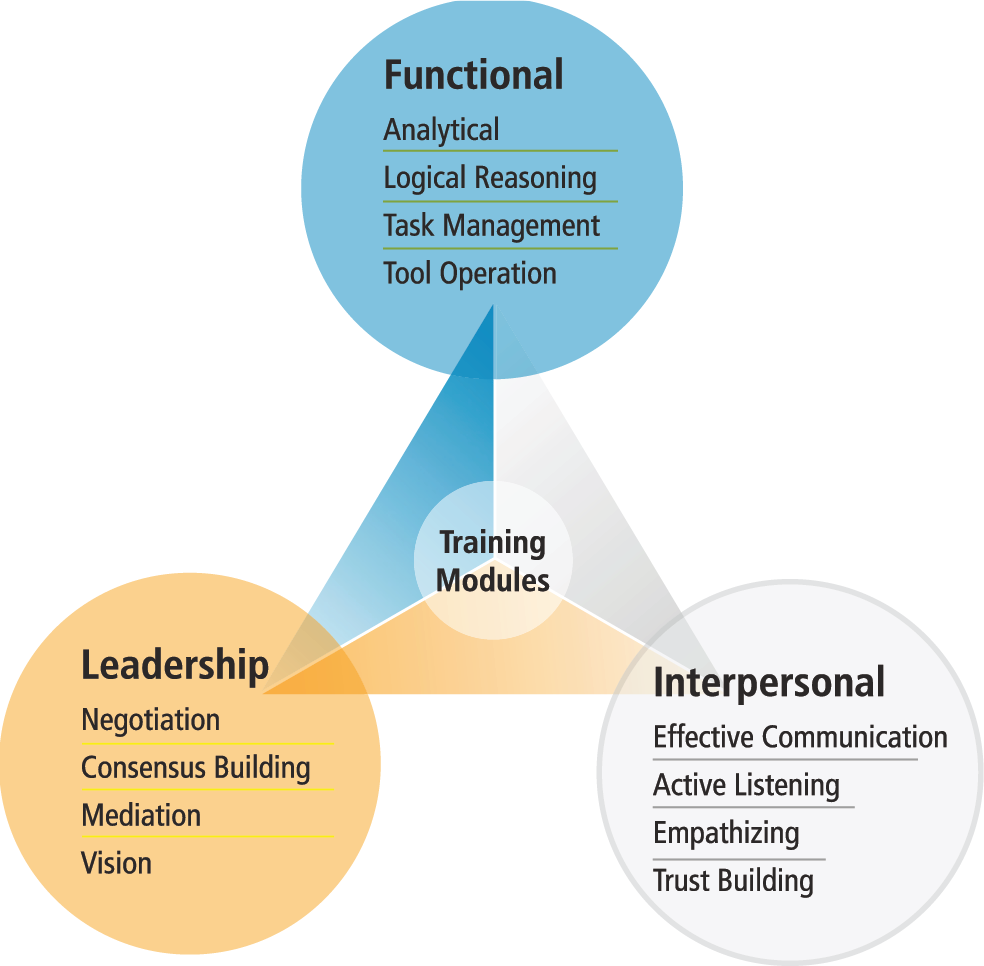

Challenge 4: Lack of Skill Sets to Leverage SRM Program for Value Creation

In many organizations, “supplier relationship” actually means negotiations over squeezing of margins and cost reductions, which invariably lead to straining of supplier relationships. As part of the SRM program, the intent is to have open and transparent supplier discussions with an aim to agree on initiatives, which, over a period of time, will lead to mutual value generation and strengthen the relationship. For these interactions to take place, it is important to actively listen to the supplier’s side of the argument. There will be situations when one has to venture beyond the conventional practices of negotiation and think out of the box.

In addition to traditional analytical skills, it is important that the members interacting with the suppliers are trained in leadership and interpersonal skills. Functional skill sets will be required to execute the analytical piece of the interaction; interpersonal skill sets will help in gaining the trust of suppliers and building stronger relationships. Leadership skills will help in diffusing tension and resolving potential roadblocks, for providing vision in supplier-specific goal building, and for inspiring internal team members and suppliers alike.

Unfortunately, in many organizations, procurement staff — who interact with suppliers — often have very little training for the relevant leadership and interpersonal skills. Business stakeholders often lack the necessary commercial skills. The core committee must identify gaps in terms of the required skills sets, ensure that the right staff are deployed and that training programs are available to bring team members up to speed for effective discharge of SRM program responsibilities.

Fig 8. Capabilities Needed in a Cross-Functional SRM Team

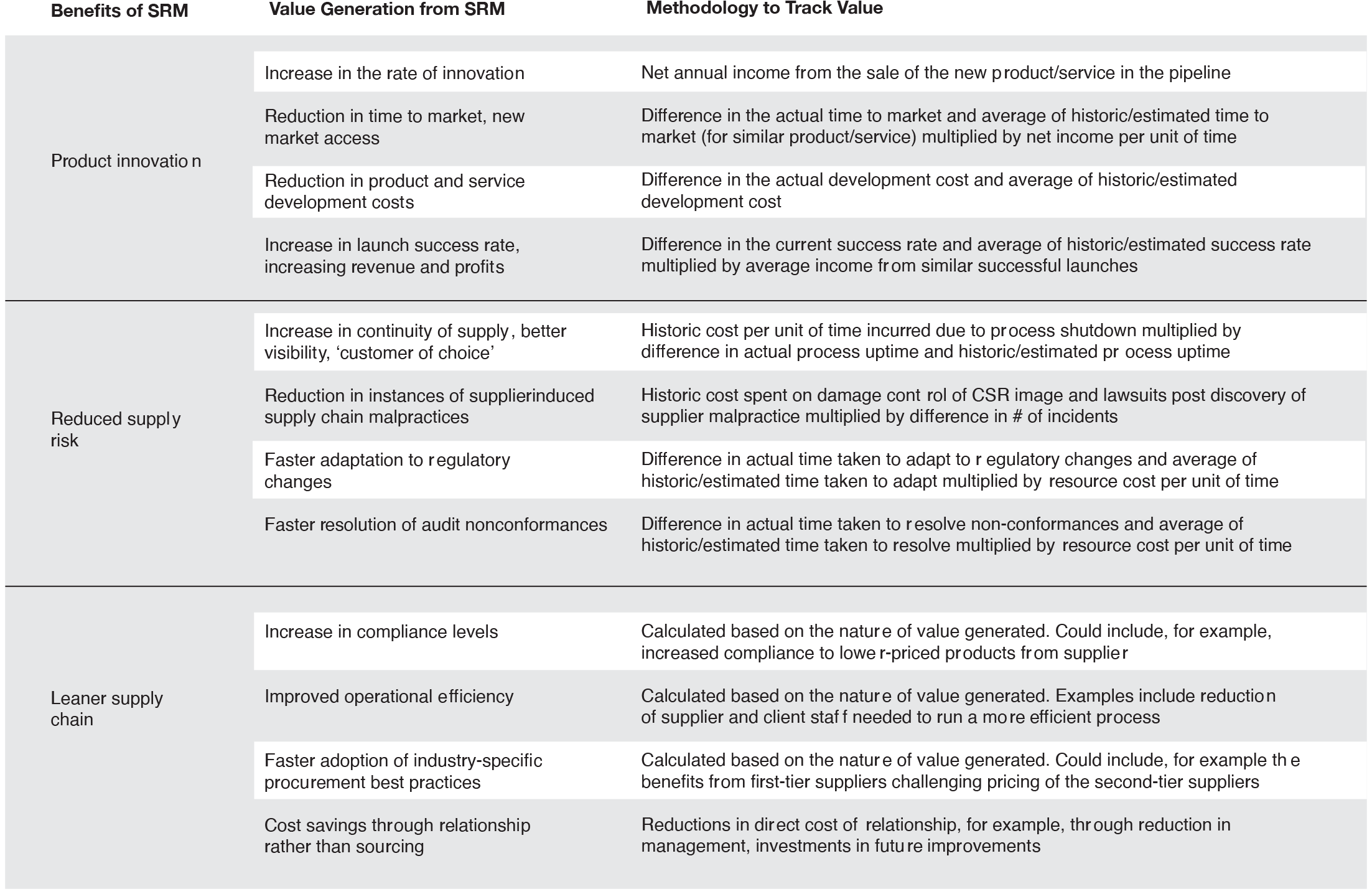

Challenge 5: Absence of Agreed Methods to Measure Value

With the initial effort put into SRM initiatives, SRM teams must track the value added to the organization to demonstrate the return on investment. Tracking of such value can also provide feedback to the core committee in terms of identifying projects paying rich dividends, so that it can prioritize such projects with limited resources. Since SRM initiatives are generally more focused on value creation rather than only cost reduction, procurement organizations are faced with the challenge of formulating creative methodologies to track the monetary value brought on by SRM initiatives. With each initiative being different in terms of results, this challenge is further exacerbated.

Creating methodologies for value tracking from SRM is often a significant challenge for procurement organizations, which traditionally focus on hard cost savings and often lack the vision of other functions when it comes to demonstrating business value. This is also partly due to a historic lack of belief in procurement savings due to inflated savings claims and ambiguous calculation methods. Procurement needs to involve other functions seeking to drive value from the SRM program and identify appropriate value measures that they use — for example, marketing will typically have a wide range of success measures for new product launches that can be used to track the benefits from engaging suppliers to support these activities.

As a best practice, the core committee should approve a range of methodologies for tracking of monetary value based on different types of SRM initiatives, and an approval from finance will provide a stamp of authentication. This approach will make the monetary value tracking process highly transparent and standardized, and provide a means for SRM team members to claim their stake in value creation, and for senior management to acknowledge their effort.

Fig 9. SRM Value Tracking Methods (Linked to Benefits of SRM in Fig. 2)

CONCLUSION

SRM can be a high-value and effective program that pays rich dividends, if executed and managed properly. Many organizations have tried implementing it in the past but have grown cynical about its effectiveness when left with no proof of value generation, often due to a combination of incorrect expectations and poor execution.

- The SRM program needs to be based on a strategy that is aligned with the wider business objectives to ensure sponsorship from senior management.

- SRM programs require cross-functional team participation, a strong and multi-layered governance structure, and centralized management to drive efficiency across the program, combined with decentralized execution to ensure effectiveness of individual supplier-specific SRM projects.

- SRM team members need to be appropriately selected and then trained in relevant leadership and interpersonal skills to ensure effective discharge of their responsibilities — traditional procurement staff often do not fit the bill.

- Organizations need to segment their supplier base effectively to customize strategies based on the characteristics of the suppliers.

- Creative, finance-vetted methodologies for measuring monetary value delivered by SRM projects need to be built for tracking the health of the program, acknowledging its value addition, giving it its due credit and securing future investment.