-

GEP Software

-

- Procurement Software

- Direct Procurement Software

- Indirect Procurement Software

- Unified Source-to-Pay

- Source-To-Contract Software

- Procure-to-Pay

- Midsize & High Growth Enterprises

- Key Capabilities

- Spend Analysis

- Sourcing

- Contract Lifecycle Management

- Supplier Lifecycle Management

- Third-Party Risk Management

- Purchasing

- Payments

- Data Analytics and Reporting

- Do more with GEP SMART

- Intake Management & Orchestration

- Intelligent Category Management

- Tail Spend Management

- Cost Data & Analytics (GEP COSTDRIVERS)

- AI-First Supply Chain Management

- Supply Chain Visibility and Execution

- Logistics Visibility

- Inventory and Warehouse Management

- GEP Multienterprise Collaboration Network

- Supply Chain Control Tower

- Field Services

- Supply Chain Collaboration & Planning

- Supply Chain Planning

- Purchase Order Collaboration

- Forecast Collaboration

- Capacity Collaboration

- Quality Management Software

- Should-Cost Modeling

- Direct Material Sourcing

-

-

GEP Strategy

-

GEP Strategy

Unrivaled supply chain and procurement expertise + the transformative power of AI

Supply Chain Consulting

- Environmental, Social and Governance

- Sustainability Consulting Services

- Socially Responsible Sourcing

- Scope 3

- Demand and Supply Chain Planning

- Collaborative Planning

- Source To Contract

- Procure To Pay

- Inventory Strategy & Management

- Operations & Manufacturing Excellence

- GEP Total Inventory Management Solution

- Network Strategy & Optimization

- Warehousing & Transportation Management

-

-

GEP Managed Services

-

GEP Managed Services

World-class skills, experience and know-how — amplified by the power of AI

-

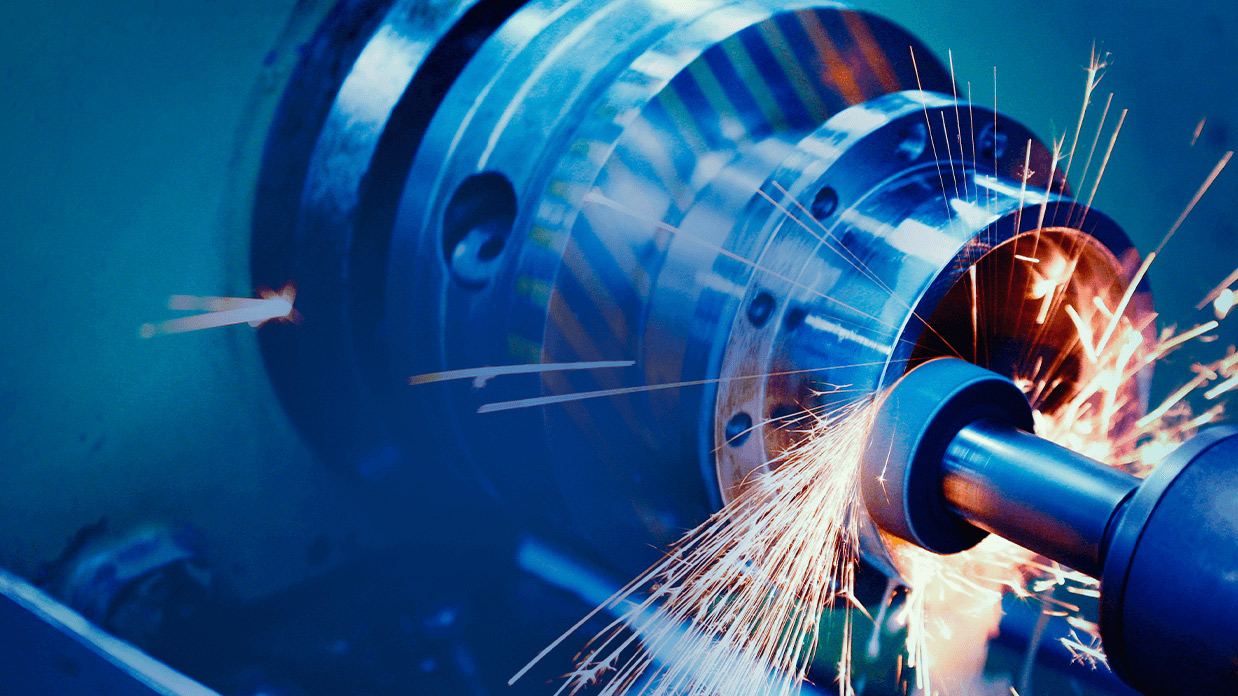

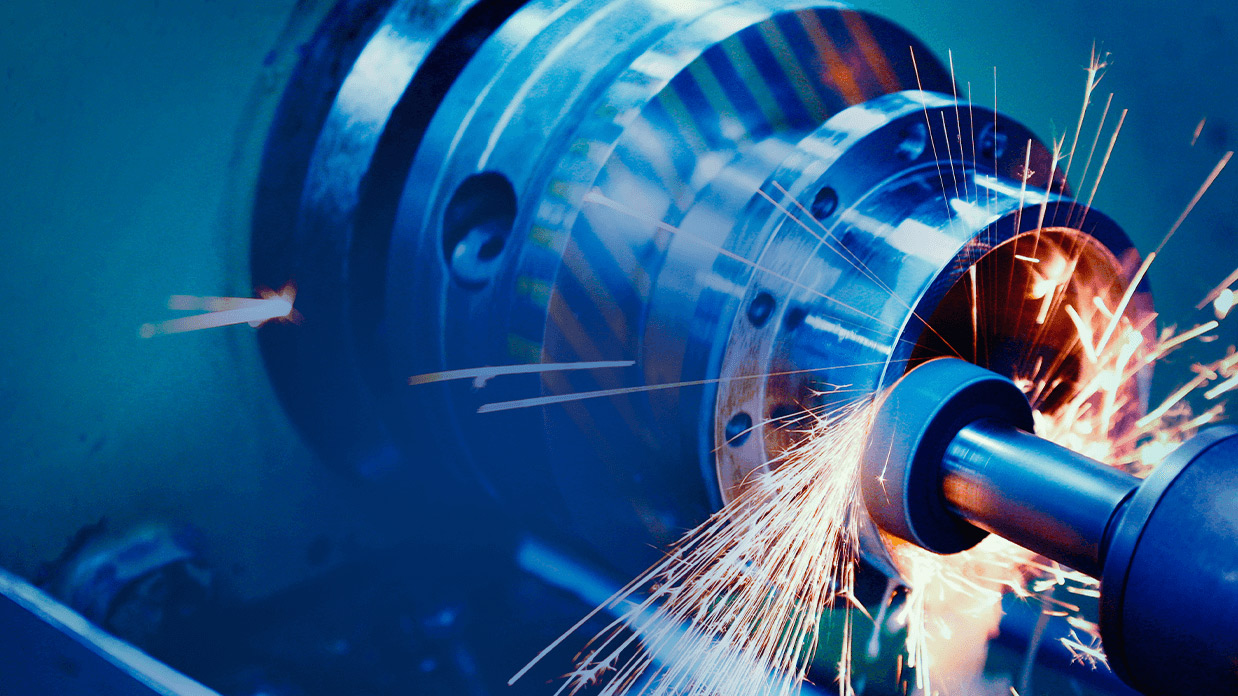

Responding to the COVID-19 Crisis in Manufacturing – With Vengat N

Continuing the "Covid Response Series, GEP Insights sat down with Vengat N. , VP Consulting, to discuss the ongoing work in developing responses to the Covid crisis with a focus on Manufacturing industries

Speaker:

Vengat N.

Vice President

Paul Blake

Director

This is a audio recording of a recent podcast.

TO LISTEN, Please Enter your EMAIL

JUST A FEW MORE THINGS ABOUT YOU