GEP SMART direct procurement software is built for enterprises aiming for peak efficiency in today’s digital, agile manufacturing environment. Managing accurate bills of materials (BOMs) is vital for procurement and supply chain teams. GEP SMART’s BOM management function enables global manufacturers to streamline BOM sourcing, procurement and spend management, getting products to market faster while reducing costs and risks. It enhances collaboration across teams and systems, ensuring alignment, cost control, and optimized inventory for timely and quality product delivery.

Transform BOM Sourcing and Procurement

GEP SMART centralizes BOM data and streamlines source-to-pay processes, enabling faster product development, cost savings, and enhanced innovation.

Unified Platform for BOM Data

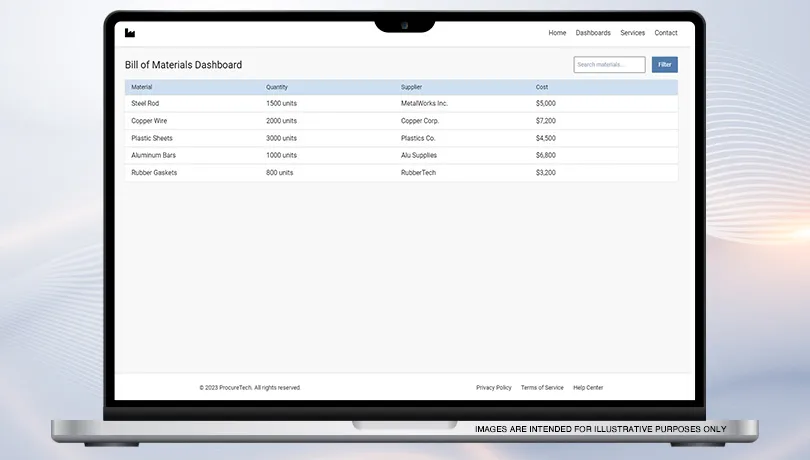

GEP SMART procurement software provides real-time access to all BOM data in a single, centralized platform. Manage all source-to-pay activities for complex, multilevel BOMs, ensuring efficient and seamless operations.

Improve Collaboration and Alignment

Enable collaboration between internal teams, suppliers and contractors with GEP SMART’s integrated workflows. Synchronize data across ERP, PLM and MES systems, keeping everyone aligned and reducing errors.

Boost Product Innovation

Accelerate product innovation and new product/feature launches and gain a competitive edge by providing accurate, up-to-date BOM data. Enhance quality, reduce defects, and ensure compliance with all global standards.

BOM Life Cycle Management

GEP SMART simplifies the consolidation and integration of component specifications, drawings, cost breakdowns and supplier info from disparate sources into a single BOM, speeding up time-to-market and optimizing costs.

Ensure Regulatory Compliance

Maintain compliance with global regulatory standards by integrating BOM data, gaining complete visibility, and ensuring that the information is accurate and consistent throughout the product lifecycle.

Augment Quality and Safety

GEP SMART ensures rigorous quality control by minimizing errors during production and ensuring compliance with global safety standards. This helps you deliver consistently reliable, high-quality products to your customers.

End-to-End Direct Materials Procurement Functions

Frequently Asked Questions

When evaluating Bill of Materials software, procurement professionals should prioritize several key capabilities. The system must offer hierarchical BOM structures that clearly represent part relationships and assembly levels while supporting multiple BOM types including engineering, manufacturing, and service BOMs. Revision control functionality is essential for tracking changes and maintaining historical records of product configurations.

The BOM software should seamlessly integrate with CAD systems, ERP platforms, and product lifecycle management or PLM solutions to ensure data consistency across the organization. The system should provide robust part classification capabilities with customizable attributes and powerful search functionality that allows users to quickly locate components based on various criteria. Cost tracking features enable accurate product costing by automatically calculating rolled-up costs as component prices change.

Advanced systems offer what-if analysis tools for evaluating alternative components and visual BOM comparisons that highlight differences between revisions. Multi-site management capabilities support global operations, while supplier management features maintain vendor information directly within the BOM. Cloud-based solutions with role-based access controls provide secure collaboration while ensuring appropriate data protection across extended supply chains.

The integration of BOM software with inventory management creates a symbiotic relationship that optimizes production planning and material availability. When properly connected, BOM systems automatically transmit component requirements to inventory systems, triggering stock level verification against production schedules. This integration enables real-time inventory allocation to specific manufacturing orders based on BOM requirements.

As engineering changes occur, the integrated system immediately evaluates inventory impact, identifying potential excess or obsolete materials. The connection also facilitates accurate inventory forecasting by analyzing BOM data against production plans, enabling strategic procurement decisions. Material requirement planning benefits from this integration through precise calculations that minimize stockouts while preventing excess inventory. Additionally, the integration supports lot tracking and material certifications directly within the BOM structure, ensuring regulatory compliance throughout the manufacturing process.

Bill of materials software and manufacturing software serve distinct yet complementary functions within production environments.

BOM software specifically manages product structures by maintaining hierarchical component relationships, engineering specifications, and revision histories. It functions as the product definition system, documenting exactly what materials comprise each product and in what quantities. BOM software focuses primarily on product data management, ensuring accurate component information flows to procurement and production teams.

In contrast, manufacturing software encompasses a broader operational scope, controlling how products are made through production scheduling, shop floor control, and resource allocation.

While BOM systems define what to make, manufacturing software orchestrates how to make it by managing work orders, tracking labor hours, monitoring equipment utilization, and collecting real-time production data. Manufacturing software typically includes quality control modules, maintenance management, and performance analytics that extend beyond the product definition focus of BOM systems.

Integration between these systems creates a seamless information flow where BOM data feeds manufacturing execution. The BOM provides the guidelines which the manufacturing software transforms into actionable production instructions. Many ERP systems incorporate both functionalities, though specialized solutions for each domain remain common in complex manufacturing environments where precise component management and advanced production control require dedicated platforms.

Bill of materials software serves as the foundation for manufacturing efficiency and product consistency. It establishes a single source of truth for product structures, eliminating discrepancies between engineering, manufacturing, and procurement departments. The software enables accurate cost calculations through precise component tracking and supports effective change management by maintaining revision history and documenting engineering modifications.

By standardizing components across product lines, BOM software can facilitate strategic purchasing decisions that leverage volume discounts. It accelerates new product introduction by providing templates and established component libraries for designers to utilize. The software also plays a crucial role in compliance management, maintaining records necessary for industry regulations and quality standards. As products become increasingly complex, BOM software provides the structured framework necessary to manage thousands of components while ensuring manufacturing precision.

A comprehensive bill of materials contains four fundamental elements that form its structural foundation.

First, component identification details include unique part numbers, descriptions, and revision levels that precisely identify each item within the assembly. These identifiers link to technical specifications, CAD files, and compliance documentation, ensuring complete product definition.

Second, quantity information specifies the exact number of each component required for the assembly, along with appropriate units of measure. This includes allowances for manufacturing waste or yield factors that affect actual procurement quantities.

Third, structural relationships define the hierarchical organization of components, indicating which parts belong to subassemblies and how these subassemblies combine to form the final product. This relationship mapping supports efficient assembly sequencing and material planning.

Finally, procurement and manufacturing attributes provide critical operational data including make-or-buy decisions, preferred suppliers, lead times, and cost information. These attributes guide purchasing decisions and production planning while supporting accurate product costing.

Together, these four elements create a comprehensive BOM that serves multiple functional areas including engineering, manufacturing, purchasing, and service.