Steel vs Aluminum: The Industrial Quest for A One-Material Solution

November 29, 2019 | Direct Materials 4 minutes read

Steel is the world’s most important and useful engineering material. It is highly ductile, malleable, tensile, corrosion resistant and has a shiny luster. By alloying steel with small amounts of other metals, you can give it almost any characteristic you want. In 2018, more than 1,800 million tons of steel1 was produced and used across construction, transportation, capital goods and various other industries. In 2018, China alone accounted for over 50% of global steel production, followed by India and Japan at 5.9% and 5.8% respectively1. Aluminum is the second most-consumed metal globally. As of 2018, approximately 25% of the aluminum shipped around the world was used in building and construction, while another 20% of it was used in the transportation industry2.

Manufacturers moving toward sustainable, low cost and durable building materials are driving the demand for steel, as it can be recycled multiple times without any substantial loss in its properties. Around 86% of the steel produced globally is recycled3. Aluminum is also recycled frequently, as it requires around 95% less energy to produce a recycled aluminum ingot4 compared with a primary aluminum ingot. Currently, 70% of the aluminum produced around the world is recycled and that number is expected to increase considerably in the next few years.

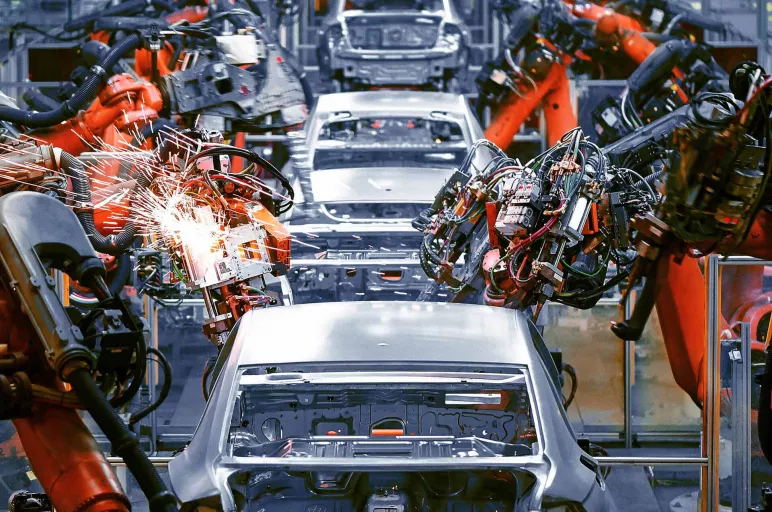

Steel vs Aluminum in the Automotive Industry

The one factor where aluminum scores over steel is its lower density, which makes it lighter than its steel counterparts. Though aluminum is lighter, it’s almost as strong as steel. In the automobile industry, a lighter vehicle translates to lower fuel consumption, improved acceleration, better braking, and easier handling. For example, the all-aluminum designed 2014 model of the Ford 150 was 300 kilograms lighter than its predecessors. This enabled Ford to boast of better fuel economy and significantly lower carbon dioxide emissions5.

However, car companies still rely heavily on steel, which remains the dominant material in automobile manufacturing. Steel still accounts for roughly 60% of the weight of an average automobile, making up the body frame, propeller shaft, seat frame, and exhaust tubes of modern cars. Steel wins out in these areas because it’s capable of withstanding the extreme pressure generated by the car and possesses high torsional rigidity. It is also cheaper than aluminum. Major steel companies such as ArcelorMittal and U.S. Steel are investing heavily in advanced high-strength steel compounds to maintain its position as the material of choice for the automotive industry.

Steel vs Aluminum in Construction

The Empire State Building in New York City held the record for the tallest building in the world for more than 40 years between 1931 and 1972, but it also pivoted the outlook of the construction industry through its large-scale implementation of aluminum in construction. The minimum design service life of aluminum is close to 80 years and it does not lose its properties between -80°C and 300°C6. Its lightness makes aluminum easier, faster and more convenient to work with, and helps reduce other costs. Moreover, the corrosion-resistant nature of aluminum makes the finished building virtually maintenance-free. For example, Ferrari World in Abu Dhabi is home to the world’s largest aluminum roof, spanning over an area of 200,000 square meters6.

Meanwhile, around 50% of the steel produced globally is used by the construction sector7. Steel possesses the structural strength required for roofs, cladding and other parts of a building. In addition to its strength and cost-effectiveness, steel’s popularity in construction is attributed to the fact that it binds well to concrete and has a similar thermal expansion coefficient as concrete, which is half the thermal expansion coefficient of aluminum.

Conclusion

While steel and aluminum share common end-uses, their applications still vary in each sector. Steel is a dominant material that is currently in favor because of its strength, corrosion resistance and economic viability. Aluminum, however, steals the show because of its high strength-to-weight ratio, which translates to relatively higher strength at a lower weight. However, it is not always economic feasible for mass construction. If aluminum or its alloys can catch up with newer, upgraded alloys of steel — as well as upcoming composite materials — a winner might be in sight. For now, however, it's a state of oscillating opinions between the two metals, for their two properties at two different price tags.

Sources

1 World Steel Association. (2019). World Steel in Figures 2019.

2 https://www.aluminiumleader.com

3 World Economic Forum. (2014). Downstream Value Chain Opportunities and Challenges in Steel and Aluminium.

4 International Aluminium Institute. (2009). Global Aluminium Recycling: A Cornerstone of Sustainable Development.

5 https://www.aluminum.org/product-markets/automotive

6 https://www.aluminiumleader.com/application/construction

7 Uses of Steel, https://www.worldsteel.org/about-steel/steel-facts.html