Picking Your Procurement Battles: A Model to Deal with Reluctant Budget-Holders

- As a baseline, a procurement policy usually meets little resistance when it aligns closely with the financial policy with regards to transactional elements.

- Procurement is frequently allowed in at the leverage and tactical category spend areas, but it can fight to be part of the big strategic supply decisions that stakeholders own

- It's a mix of politics and rational decision-making in procurement that the best CPOs manage with aplomb without sacrificing broader company values.

August 26, 2022 | Procurement Strategy 6 minutes read

One of the thorniest issues in private sector procurement is the spend pools that are “sacred cows”. Examples are abound.

- The general counsel who negotiates all the legal providers

- The marketing director who directly extends the ATL agency without competition

- The CEO direct award to a strategy consulting house which is a 'done deal' as it crosses the professional buyers desk

- The partnerships team- because its suppliers generate revenue for the business then it’s not a cost play and procurement doesn't get involved

- The brokerage fees and other commissions that drive incentives and vary significantly

As a new CPO entering the post with ambition to make a difference, do you force yourself in or let it go (and hope, probably in vain) that you will be allowed in one day?

In the face of more powerful stakeholders, what does a CPO and her team do?

This blog offers a decision framework for deciding the role for you to apply to your environment as you consider whether the fight is worth it.

Also Read: Your Perfect Procurement Investment Pitch Storyboard For C-Suite

The State of Play in Procurement's 'Reach'

As a baseline, a procurement policy usually meets little resistance when it aligns closely with the financial policy with regards to transactional elements: all purchases must flow through approvals in an approved system, for example.

The concept of using 'approved' suppliers where basic checks have been conducted is also widely accepted. This clearly supports payment, risk and financial controls as well as provides some audit trail and visibility. Besides, ‘placing an order’ has been a standard business practice for decades.

A positive concept that has gained traction in recent years is ‘guided buying’. Using a panel of preferred and/or approved suppliers (provided by the procurement team) and providing the end user an easy means of selecting those (or competing them).

This supports procurement's extended influence, but the impact of this lever has (mostly) been on high-volume transactional areas. It has gained limited traction in 20% of the suppliers that account for 80% of a company spend.

Procurement policies that define the function as ‘custodian ‘of all external spend usually are over-reaching, given capacity constraints. Policies therefore tend to allow freedom to stakeholders to buy as they wish for low-value and low-risk purchases.

The worst procurement policies are essentially “secure 3 quotes” before you buy.

Good procurement policies for larger buys usually stipulate to: (a) involve procurement and involve us early; (b) define your requirements optimally; (c) compete requirements wherever possible; (d) use good contract terms and (e) manage your suppliers effectively over the life of the engagement.

You’ll hardly find a procurement policy that has been enforced through sanctions. However, the involvement of procurement (or not, or a contract admin only) is the source of much frustration. Powerful stakeholders can often get away with a shrug and guffaw when they pseudo-sheepishly beg forgiveness for not following policy again.

Also read: How A New CPO Can Pick The Right Savings Transformation Flavor

Sidelining of Procurement... But Why?

Putting yourself into the shoes of the budget-holder, you’ll see four main reasons for the sidelining:

- Company culture. Where a business has deemed that the business lines are entrepreneurs who need freedom to be agile and perform, then central shared service functions like procurement and HR will be viewed as ‘use when I need them only’, not functions that should always be consulted for major topics.

- Misalignment on priorities. There will a couple of unhealthy environments where the central functions are actively being avoided by the business units/ stakeholders on account of previous issues and misaligned goals.

- "Specialism". The unique character and complexity of our supply market landscape requires decades of experience that a junior would never bring value to. The stakeholders view themselves as the experts here.

- Procurement's reputation. Procurement slows things down, add unnecessary time and process to decision making. Or worse, seek to reduce budgets so they can justify their value to finance. They may even make the budget-holders’ team look like they've been asleep at the wheel, so they don't want procurement anywhere near.

The Battleground and Whether To Fight There

In fairness to the stakeholder, procurement is frequently allowed in at the leverage and tactical category spend areas. Print in marketing. Software renewals in technology. Soft FM in facilities. However, it’s the big strategic supply decisions that stakeholders own where the battleground can exist.

The general principles of whether to pick a battle are widely written about:

- Does the issue in question tie to one of your department or company priorities? Does it conflict with company values?

- Even though you disagree with the idea or approach, can you live with it? Are you setting a precedent that if widely adopted would be damaging to your wider goal?

- Has this person outwardly supported one of your ideas in the past? Can you 'trade' goodwill as a one-off to support a wider strategic aim?

- Do you have allies you can call on that will support you? Or will you, despite strong rational arguments, be in a minority, nevertheless?

- Does this battle have a neutral or positive impact on your health and the health of your team? Fighting involves personal risk, takes time, consumes energy. Is it worth it?

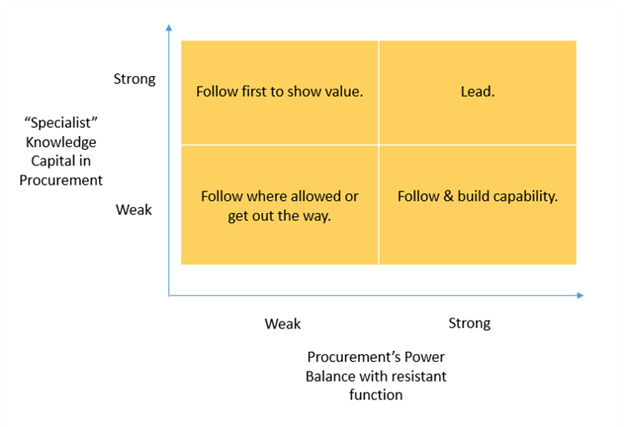

Taking all these inputs, the following decision model supports your strategy and tactics at a sub-category level:

On the ‘x’ axis is the probability of successfully enforcing change based on a judgement of the power balance right now. Factors that support the analysis of this dimension include:

- Sponsorship from your board executive and her standing, based on the arguments/ business case

- Timing/ the need to find value in the supply chain

- Historical relationships and the extent central functions have enjoyed influence in the past

On the ‘y’ axis is the ‘knowledge’ held right now in the procurement team:

- Are you an expert on the supply market (not just the procurement process)? Can you bring new ideas and insight that will trigger a difference in working practices (not merely, ‘lets run an RFP?’)

- Is the purported ‘specialism’ of the spend pool surmountable? And does the procurement team possess it? Whilst many excellent generalists make a big impact on many categories, when faced with a resistant stakeholder, credibility in conversations is essential.

Based on these two dimensions, four options exist:

1. Follow first (then lead)

The mantra can be “demonstrate the quick wins/value in the low-tension areas and we will earn the reputation to be involved upstream”. This has mixed long term results and carries risk. The middle management who typically look after these areas are indeed grateful recipients and become procurement's advocates. But this doesn't necessarily flow upwards.

2. Lead

Here's we've chosen to go for it. The battle is worth it, and we think we will win. Planning, communications and change management (and patience), alongside strategic sponsorship will all be critical here to insert procurement's expertise into the function.

3. Follow where allowed or get out the way

Offer a one-year policy waiver. Provide a resource in as a token/bridgehead to stay close and provide support (and build attention). Be there to help and keep channels of communication open.

4. Follow and build capability

Play the longer game. Take time to build knowledge: bring in external help (hire or from professional services firms). Poach a member of their team into your team as a secondee if you can. Conduct knowledge sharing and build bridges. Then make your play.

It's a mix of politics and rational decision-making in procurement that the best CPOs manage with aplomb without sacrificing broader company values. And it's always a fine balance. With a decision model as a guide, hopefully the journey will be easier.

Turn ideas into action. Talk to GEP.

GEP helps enterprise procurement and supply chain teams at hundreds of Fortune 500 and Global 2000 companies rapidly achieve more efficient, more effective operations, with greater reach, improved performance, and increased impact. To learn more about how we can help you, contact us today.

Graham Copeland

Senior Director- Business Development

Graham leads business development of the services organization for the UKI region. He has 25 years of procurement and sales leadership experience and has worked as an employee and a consultant with Schlumberger, Coop Group, Tesco Bank, BP, ABN Amro and Deutsche Bank. At GEP, he helps CPOs with operating model decisions and procurement transformations. He also runs the Proctopus procurement community. Graham holds a Bachelor’s degree in engineering and business from The University of Strathclyde.