The Turf War Between Procurement and Vendor Management (And How to Resolve It)

- When dealing with one another, procurement and vendor management teams often experience tension and mistrust

- Is there a design decision framework they can use to improve the situation?

- Fixing the operating model is the best way to minimize conflict. A 2x2 model shown in the blog can support mutual decision-making

February 25, 2022 | Procurement Strategy 5 minutes read

If you’re a supply-side commercial professional and have worked for a mid-to-large-sized enterprise with a sizeable IT spend, you've most likely experienced the tension, the mistrust, and the turf war hidden behind masks of congeniality.

We are talking about the broken operating model between procurement teams and vendor management (VM) teams.

One can find this friction across organizations. Sometimes it’s a small issue’ sometimes a big issue, but never widely discussed. It’s often swept under the carpet and uneasy truces are formed to make-do.

Is there an operating model design decision framework you can use to improve the situation for procurement as well as vendor management?

But before we answer this question, let’s first take a detour to define strategic vendors and why procurement and VM teams do not see eye-to-eye.

The scope of VM is usually limited to strategic vendors.

Most large firms segment their supply base by criticality/spend (or both) and determine if the most critical/important suppliers require a vendor manager.

Strategic suppliers typically benefit (or suffer!) from a greater level of governance and strategic and operational interactions.

This gives them the opportunity to build closer relationships across the buying organization to understand the client needs better, and, theoretically, to have a greater opportunity to win more business and grow the account. The downside is typically greater exposure when things aren't working well and more administration in managing the account.

Strategic vendor management does not cover day-to-day order placement and issue resolution, purchase order placement and expediting. This is always going to require business ownership.

What is broken between procurement and vendor management?

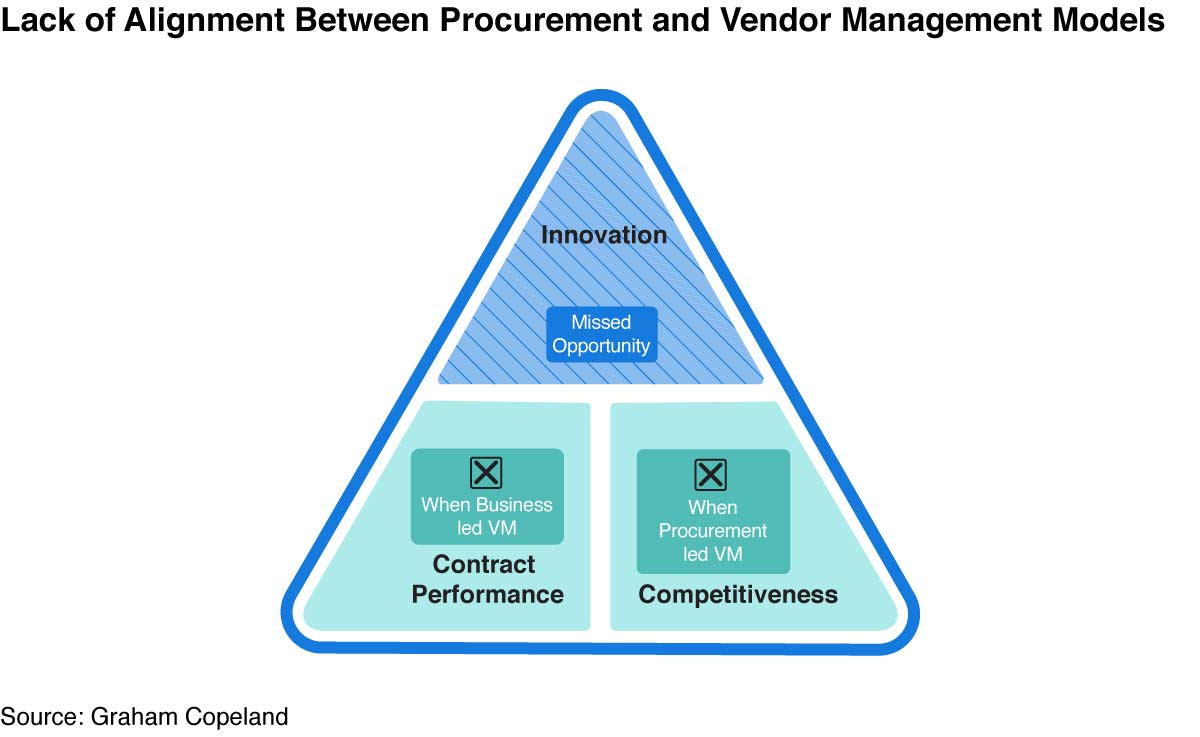

Despite broadly having the same overarching aims -- to extract maximum value and protect their employers’ interests from the supply base -- there is significant mistrust between the two functions. The triangle diagram below represents a hypothesis that a lack of alignment between procurement and vendor management models means the goal of innovation is ineffectively exploited and represents a missed opportunity cost for business.

When vendor management is business-owned, operational effectiveness takes priority over other factors. Procurement can eye this suspiciously, viewing vendor management as tactical and day-to-day operational gophers. Surely, they are missing significant optimization opportunities as they are not commercial enough; not driven to change and improve like procurement?

On the other hand, when procurement muscles in on VM’s activities, the VM team eyes procurement defensively. This procurement crowd is willing to burn trust and relationships, burn bridges to save a dime.

They don't appreciate that you can’t RFP your way out of every situation and that there is give and take needed to make a contract work. And they don’t understand the intricacies of the business requirements because they swoop in and out sporadically, creating explosions that need repair.

Of course, these are caricatures and there would be beautiful procurement and VM relationships out there.

But do note the high level of skills overlap between the two groups. Many VM leaders and teams start life in procurement. Naturally, when a big commercial ask lands on a supplier, VM can feel well-equipped to deal with it without procurement. That lack of skills separation will naturally lead to a ‘treading-on-toes’ situation, which can add to the friction.

Closing the gap between procurement and VM through effective op model decisions

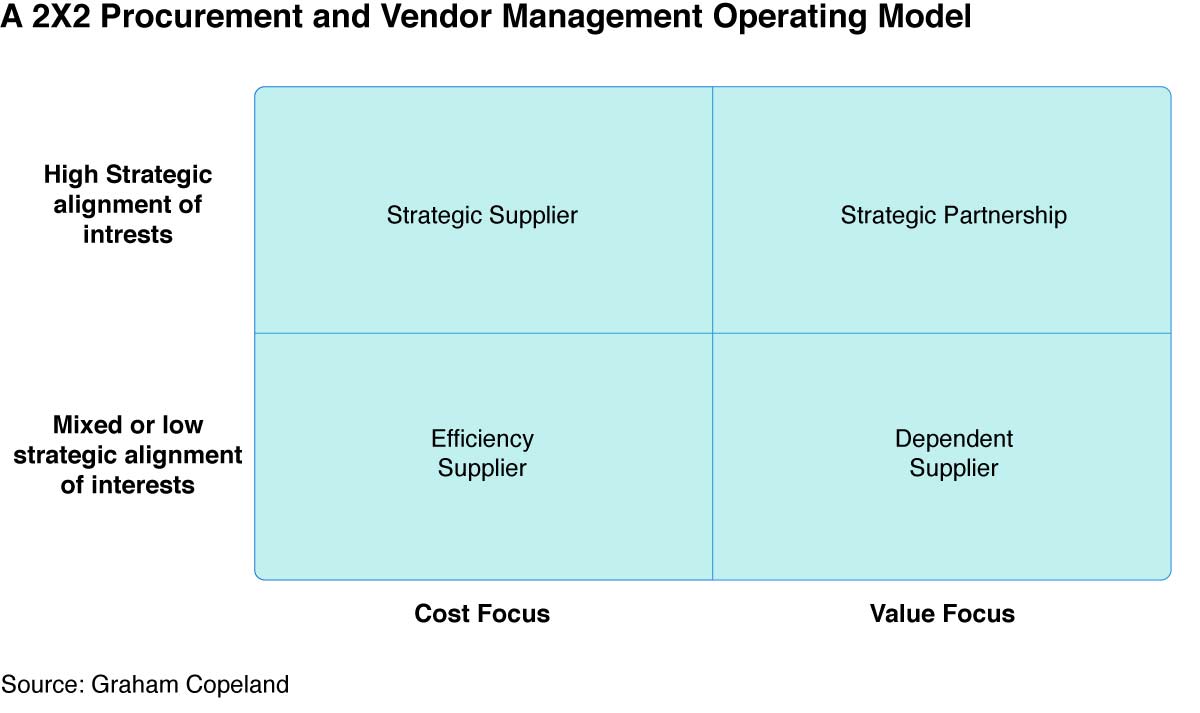

Fixing the operating model is the best way to minimize conflict, like this 2x2 model to support decision-making on which categories/ strategic suppliers should be managed where the key dimensions are:

(a) The level of alignment of interests between supplier and buyer

(b) The focus of commercial activity is either cost-efficiency or value-based

By mapping strategic suppliers to this model, you find four potential solution models for the relationship aspects:

1. Strategic Partner:

Here, both parties are co-developing their businesses, innovating, and developing offerings and are aligned on creating value. An example would be a bank’s relationship with partners such as Travelex or Western Union if they don't want to build that service in-house. Ownership here is typically held within the business, with procurement playing the supporting role.

2. Strategic Supplier:

Not requiring significant innovation but instead a job well done, large operational partners who service industry verticals would be examples of strategic suppliers. Proximity to the business is important but not critical. So, the determination of ownership in procurement will depend upon company-specific factors like individual staff know-how and relationship history.

3. Efficiency Supplier:

Here there is strong mutual alignment, but the emphasis is on removing waste from the supply chain to get things done more efficiently and safely. An example would be a 3/4 PL logistics provider. Ownership here would be suited to procurement leadership with support from the business.

4. Dependent Supplier:

This scenario would typically include many of the big SaaS and cloud platforms. Few organizations will individually have the scale to align strategically with the giants but they are critical to business operations. Again, a case-by-case review is needed to determine where relationships will have the biggest leverage. Typically, but not always with the chief information officer.

Other factors may need to be considered, including the number of business lines or stakeholders that use the supplier and whether one is a dominant user. Also, consider the appetite/willingness of the senior executive responsible toward delegating strategic aspects of the relationship.

Closing the gap through 'patches'

If the fix of an operating model re-design is too daunting, here are 5 tips to patch up the ways of working for the buyers and VM:

1. Joint leadership and communications between VM and procurement leaders:

Have the CPO and VM leaders share stages when communicating to their own teams and at supplier days.

2. Leverage 'top-to-top' relationships:

Use C-suite to C-suite connections to engender commitment from all parties and build energy.

3. Clarity on the RACI matrix for activities that involve VM:

Both Procurement and VM should have clear roles over the contract lifecycle. Should procurement join monthly, quarterly and monthly reviews? Who will be the point of escalation in the event of major incidents?

4. Team building between the two functions:

With shared leadership visionaries, trust-building and the operational level can be facilitated too.

5. Build strong communications loops on vendor performance and activities:

Whoever ends up owning the VM activity, there needs to be created clear and regular engagement paths to identify the current and future status of vendor performance.

Turn ideas into action. Talk to GEP.

GEP helps enterprise procurement and supply chain teams at hundreds of Fortune 500 and Global 2000 companies rapidly achieve more efficient, more effective operations, with greater reach, improved performance, and increased impact. To learn more about how we can help you, contact us today.

Graham Copeland

Senior Director- Business Development

Graham leads business development of the services organization for the UKI region. He has 25 years of procurement and sales leadership experience and has worked as an employee and a consultant with Schlumberger, Coop Group, Tesco Bank, BP, ABN Amro and Deutsche Bank. At GEP, he helps CPOs with operating model decisions and procurement transformations. He also runs the Proctopus procurement community. Graham holds a Bachelor’s degree in engineering and business from The University of Strathclyde.