Procurement and Supply Chain Align on Goals But Falter in Execution, Shows NC State University Study

- Procurement and supply chain operate in silos, hampering alignment between key processes.

- AI-powered orchestration enables real-time collaboration and creates shared visibility across procurement and supply chain operations.

- Functional leaders are now using Generative AI to align complex processes that require quick decision-making.

October 03, 2025 | Procurement Strategy 4 minutes read

Latest research by North Carolina State University (NCSU) and GEP suggests that there is growing strategic alignment between procurement and supply chain.

However, there are many gaps in execution and technology adoption, particularly around AI integration, the research adds.

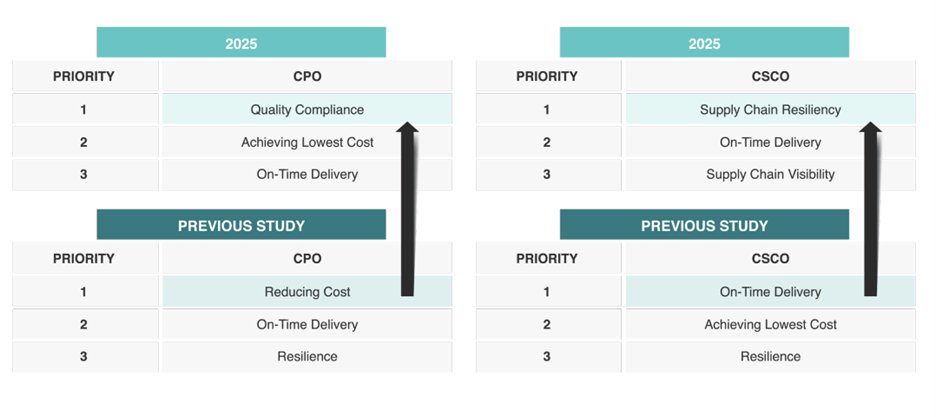

Chief procurement officers (CPO) and chief supply chain officers (CSCO) are increasingly focusing on building resilience, quality compliance, and sustainability. These objectives have moved to the top of their agenda, surpassing traditional cost and delivery metrics. This expansion in functional scope signals a shift toward a more customer-centric and long-term view of supply chain performance.

While cost management still is part of the equation, it is no longer the sole parameter for decision-making.

source: Bridging the Procurement & Supply Chain Gap | GEP

Now here’s the thing. While the priorities of procurement and supply chain are converging, operational divides and misalignment are hampering implementation.

Where do these divides break alignment? More importantly, how can these barriers be removed?

Operational Misalignment Is Impacting on Several Fronts, Adds NCSU Study

Gaps in execution between procurement and supply chain are leading to strategic implications. Higher costs, longer cycle times and reduced resiliency are the top three consequences, shows the NC State University report.

Differences in focus slow decision-making, create inefficiencies, and weaken the ability to respond to disruption. Over time, these disconnects hurt strategic goals of building resilience and quality standards.

Bridging gaps calls for procurement orchestration to align fragmented functions and turn shared strategy into coordinated action. But what exactly does orchestration mean?

What is Procurement Orchestration?

Procurement orchestration aims to align people, processes, and technology to create a unified operating model and optimize procurement outcomes. This model moves beyond the traditional siloed view of procurement and supply chain management. It connects upstream planning with downstream execution and synchronizes sourcing decisions, supplier actions, logistics flows and risk mitigation efforts.

With AI as a key enabler, orchestration seamlessly connects all procurement functions, including intake, sourcing, contract management, payments and supplier collaboration. This enables real-time collaboration and creates shared visibility across procurement and supply chain operations.

By connecting the end-to-end source-to-pay process, orchestration not only streamlines workflows but also creates deep connections across suppliers, external systems, and wider business networks.

The concept of total orchestration for procurement includes both front-end and back-end aspects. Intake management, on the front end, enhances the user experience, making procurement accessible and intuitive.

How Technology Makes Orchestration Possible

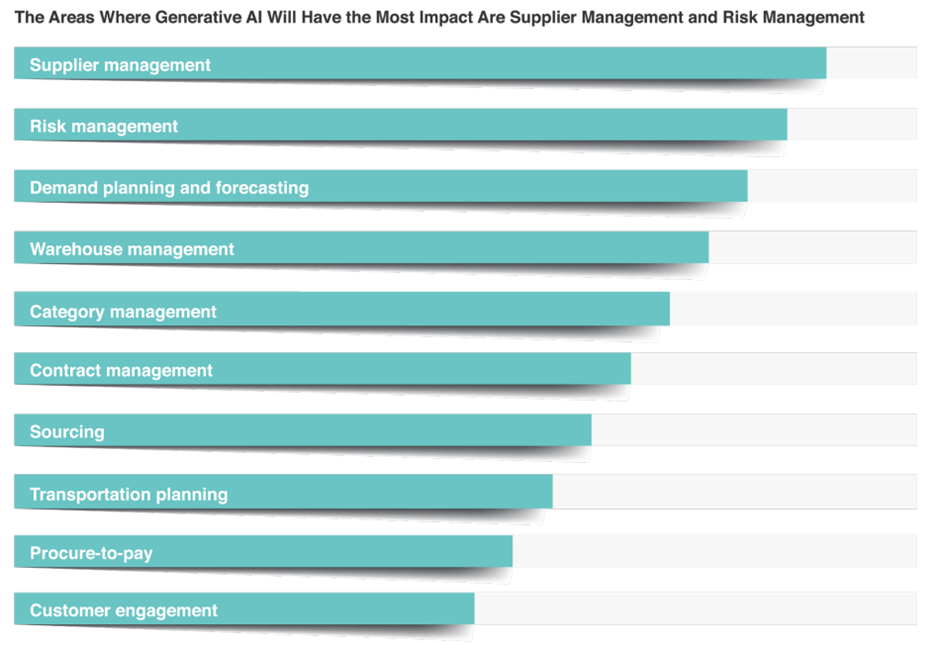

Leaders increasingly view Generative AI as the top technology for aligning procurement and supply chain, especially for complex processes that require quick decision-making. These include supplier management, risk forecasting and demand planning. Warehouse management, category management, sourcing and contract management are also getting aligned with this technology.

source: Bridging the Procurement & Supply Chain Gap | GEP

Generative AI helps teams detect inconsistencies early, model different scenarios, and adjust operations based on dynamic conditions. It also drives digital transformation initiatives together with low-code platforms, IoT networks, and advanced analytics.

Not surprisingly, businesses leading the AI race are embedding generative AI into the core of their operating models.

Too Many Gaps in Procurement and Supply Chain Operations?

Get AI-Powered Orchestration to Bridge These Gaps and Turn Strategy into Action

Barriers to AI Adoption

Businesses need to overcome a few challenges before they can adopt advanced technology.

• Data security and quality

Data security and quality are the biggest challenges to implementing AI in procurement and supply chain operations. Without reliable, integrated data, even the most sophisticated AI models struggle to deliver actionable insights. If data isn’t accurate, AI is also likely to provide inaccurate results.

• Ineffective change management

Lack of training and identifying the right solution provider are among the other key challenges. Skills gaps mean that teams often lack experience with AI tools and orchestration processes. Resistance to change also stalls progress, with orchestration requiring teams to adjust quickly to new ways of working and performance metrics.

• Distinct operational priorities

Another key challenge is the difference in approach toward AI integration. Procurement and supply chain leaders often struggle to align on how to integrate AI into existing operations, even though they recognize its value.

While chief supply chain officers (CSCOs) are more concerned about technological barriers such as data quality and privacy, chief procurement officers (CPOs) are apprehensive about people-related challenges including fear of job displacement and lack of training. Difference in approach makes it difficult to quickly develop a unified AI roadmap and deployment plan.

A Roadmap for Procurement and Supply Chain Alignment

To succeed in aligning procurement and supply chain operations, businesses must follow a clear, deliberate path and take targeted steps to turn strategy into action.

- Drive collaboration in strategic areas such as risk reduction and financial outcomes

- Invest in technology to enhance coordination and workflow efficiency across supply chain and procurement

- Drive AI adoption and pilot agentic AI projects in converging areas like risk and supplier management

- Improve mutual understanding in AI implementation and balance the technical and human efforts to make the transformation successful

One thing is clear. Businesses that invest in operational and human readiness will be better equipped to integrate AI and unlock synergy between procurement and supply chain.

To kick off the process, businesses must invest in high-quality data, digital training, and cross-functional alignment. More than a technological upgrade, orchestration is an operational shift that requires buy-in from different stakeholders across the enterprise.

To know more about the next steps in aligning procurement and supply chain operations, read the GEP white paper.