Struggling With MRO Spend? Here Are 5 Strategies for MRO Category Management

- Effectively managing a wide and complex mix of products and services in MRO is a key challenge for category managers.

- To minimize the downtime and mitigate the impact on production, category managers often engage in overstocking, which strains the budget and leaves them with dead inventory.

- Businesses must leverage advanced technology solutions to improve spend visibility, reduce ad-hoc purchases and automate routine tasks.

August 21, 2024 | Procurement Strategy 4 minutes read

Does your business know exactly how much it spends on maintenance, repair and operations (MRO) activities? Do you have a handle on several purchases made in this indirect spend category?

Most likely, you would not have a definite answer. Perhaps because MRO procurement is decentralized and overlooked by purchasing teams. And while this spending is necessary, it is not as strategic as the spend in some direct categories.

Most businesses cannot effectively manage their MRO supplies, which leaves a high volume of dead inventory that drains the budget.

Category managers are under immense pressure to keep production running and eliminate the risk of downtime and outages. As they look to identify and mitigate potential threats to production, they often stock surplus inventory, a majority of which remains unused.

Additionally, MRO spend is spread across multiple sites and categories, with many unique SKUs prompting a just-in-case buying strategy.

A high volume of spot buys adds to lack of spend visibility, with unplanned purchases accounting for a high portion of the total MRO spend.

And demand remains unpredictable, with about 70% of MRO items turning less than once every two years.

Despite all these challenges, there is an opportunity for MRO category managers to streamline inventory management and lower costs while mitigating risks at the same time.

Let’s look at a few ways they can succeed in these objectives.

Strategies for Effective MRO Category Management

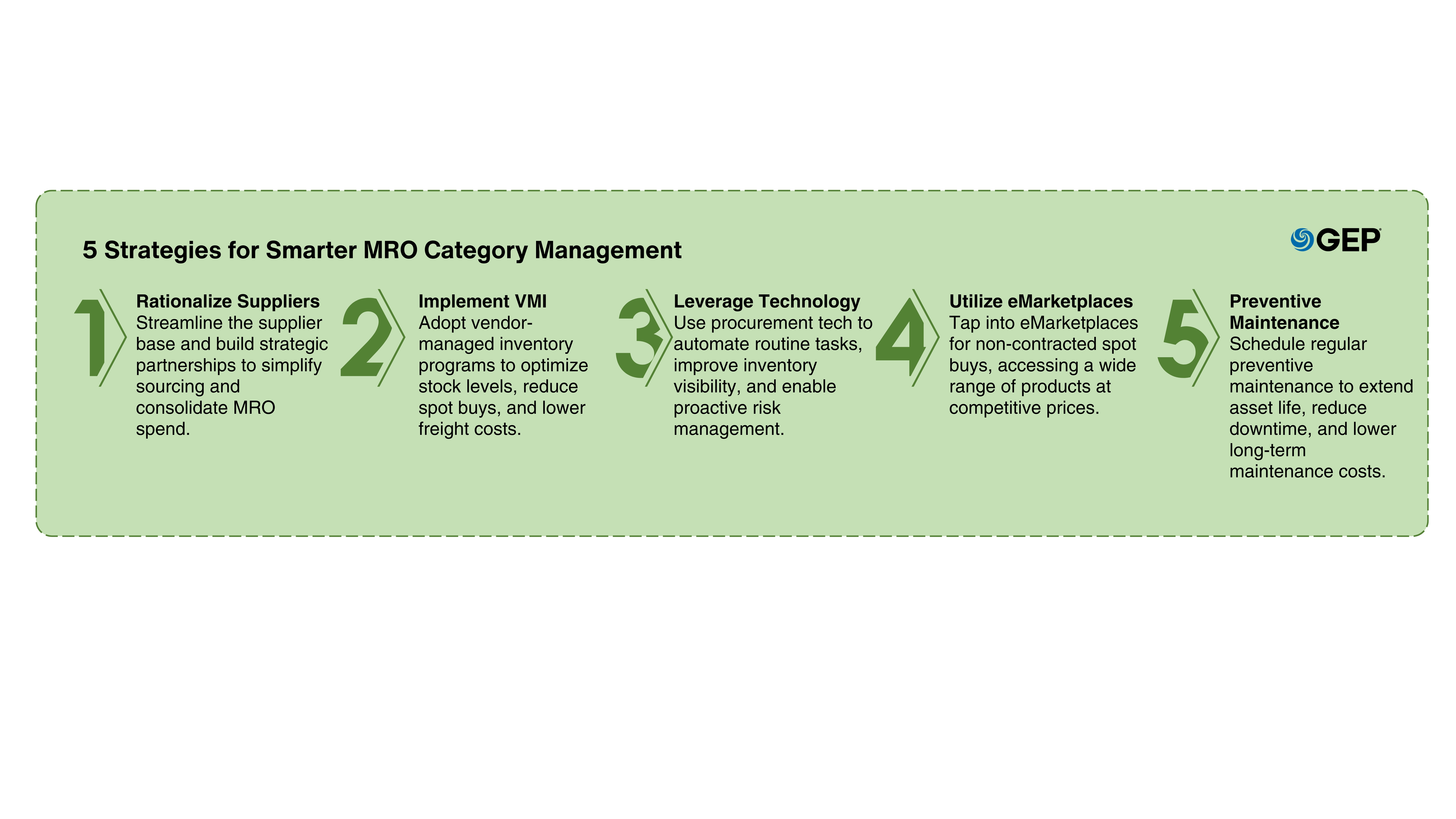

1. Limit the supplier base:

Supplier rationalization is a key strategy for MRO category managers. While this essentially means reducing the number of suppliers, it also means building strategic partnerships with key suppliers who supply a large number of products.

2. Launch a VMI program:

With a vendor managed inventory (VMI) program, you allow suppliers to take full responsibility of the stock. This reduces overall consumption, improves expenditure management and minimizes the workload on procurement teams. Better inventory management, in turn, reduces costly spot purchases and expedited freight charges.

3. Leverage technology:

Category managers now have an opportunity to leverage procurement technology to automate routine tasks and improve inventory visibility. They can also push for greater catalog coverage and capability for advanced alerts on item availability challenges. This will help them reduce spot-buy volumes and plan proactively for supply chain risks.

4. Explore emarketplaces:

Category managers can also consider emarketplaces for non-contracted spot-buys. Many of these emarketplaces offer a wide range of products at competitive prices.

5. Engage in preventive maintenance:

For the MRO category, the business must schedule preventive maintenance at regular intervals. This can help increase the lifespan of different parts and keep operations running seamlessly for a long time. It can also help lower maintenance costs in the long term.

Where to Start

At the outset, you need to oversee MRO procurement and inventory management with the same rigor and focus as mainline spend categories.

Identify products and services that fall under this category. While these can vary for different businesses, the objective here is to identify and separate MRO and indirect spend to simplify internal financial, accounting and reporting structures.

Additionally, businesses must also quantify the role of MRO in overall performance. To do this, they can compare MRO activities with inventory management standards used for production procurement.

Analyze the maintenance expenditures, costs of stockouts, expedited freight charges as well as other expenses that can potentially occur. This analysis can present a strong case to centralize MRO category management across the enterprise.

As you streamline processes and minimize ad-hoc spend, you will witness MRO spend declining over a period and reducing to a small portion of the overall procurement budget.

A GEP Case Study on MRO Procurement

With inconsistent structures and processes across regions, limited spend data visibility and non-standard metrics, a global consumer foods manufacturer could not effectively manage its MRO category spend.

Category managers remained unsure and struggled with decision-making.

The manufacturer decided to partner with GEP to refine sourcing and category management, create organizational capacity and ensure adherence to policies and code of conduct.

This partnership succeeded in achieving the desired outcomes. GEP helped the company achieve significant improvements in their indirect category management process.

By adopting an integrated, technology-driven approach to procurement, the food manufacturer could realize $50 million in savings from a managed spend of $1 billion.

To learn more about the benefits of deploying advanced procurement technology and strategies for the MRO category, read our detailed case study.