Think You Know Your Suppliers? Let AI Agents Evaluate Supplier Performance

- AI agents turn fragmented supplier data into a live, connected view of performance.

- Spot risks and act faster, with clarity and control at scale.

October 28, 2025 | Supplier Management Strategy 6 minutes read

Let’s start with what’s familiar. Every supplier affects your cost base, quality standards, and operation cycle. Most organizations track that through KPIs like on-time delivery, quality, cost competitiveness, responsiveness, and contract adherence. These are standard indicators.

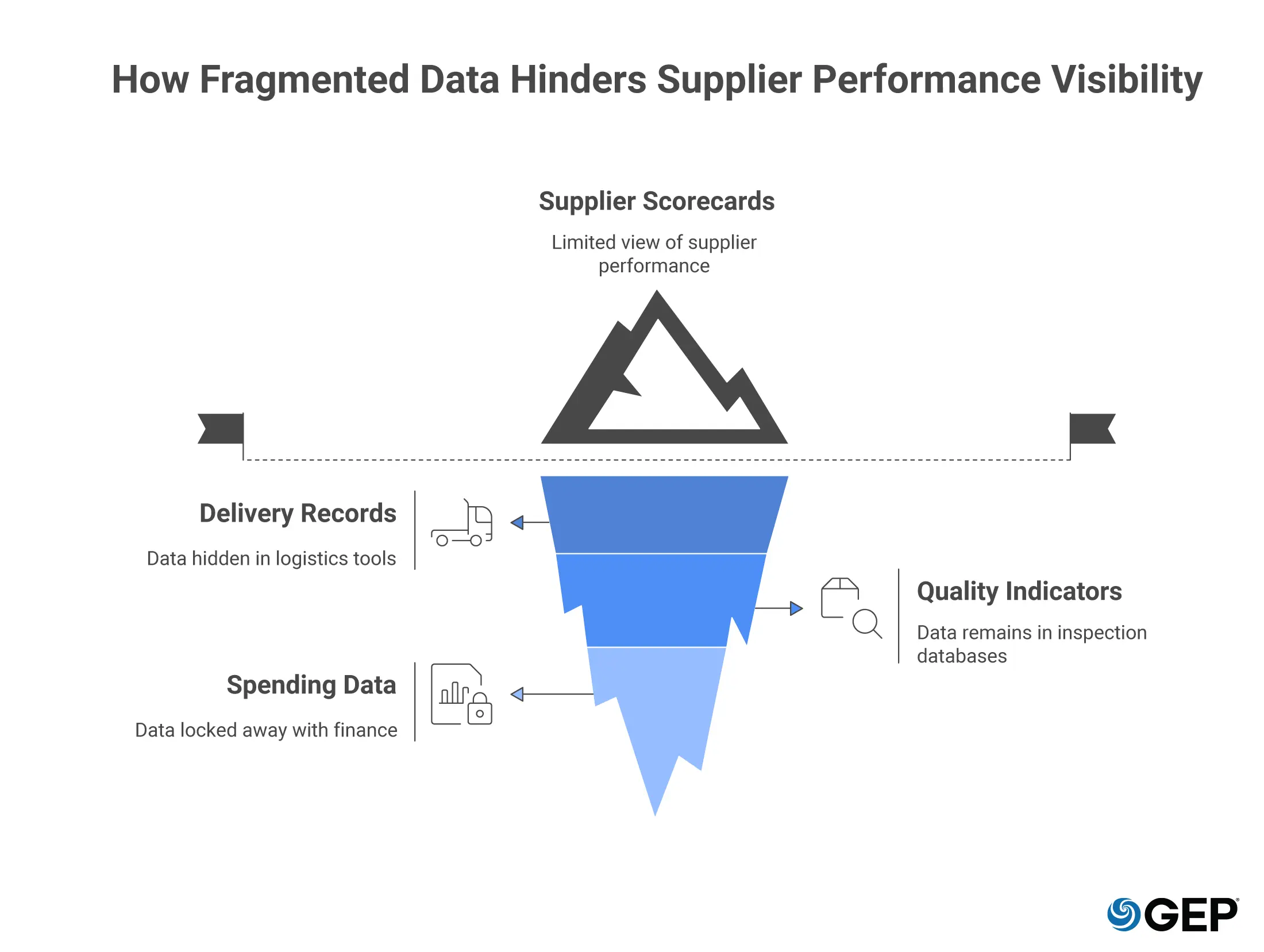

But here’s the challenge: the data behind KPIs lives everywhere. Delivery records hide in logistics tools, quality indicators remain in inspection databases, and spending is safely locked away with finance.

You can’t improve what you can’t see. Fragmented information turns supplier scorecards into still frames when what you need is a full, evolving picture. AI agents fill this visibility gap. They bring the scattered pieces of procurement together, giving buyers a clear, living view of how each supplier performs.

Let’s look at how AI agents can improve supplier performance evaluations, the core capabilities to look for, and what it takes to deploy them responsibly to benefit procurement companies in the long term.

Talk to Our Expert

How AI Agents Impact Supplier Performance Evaluation

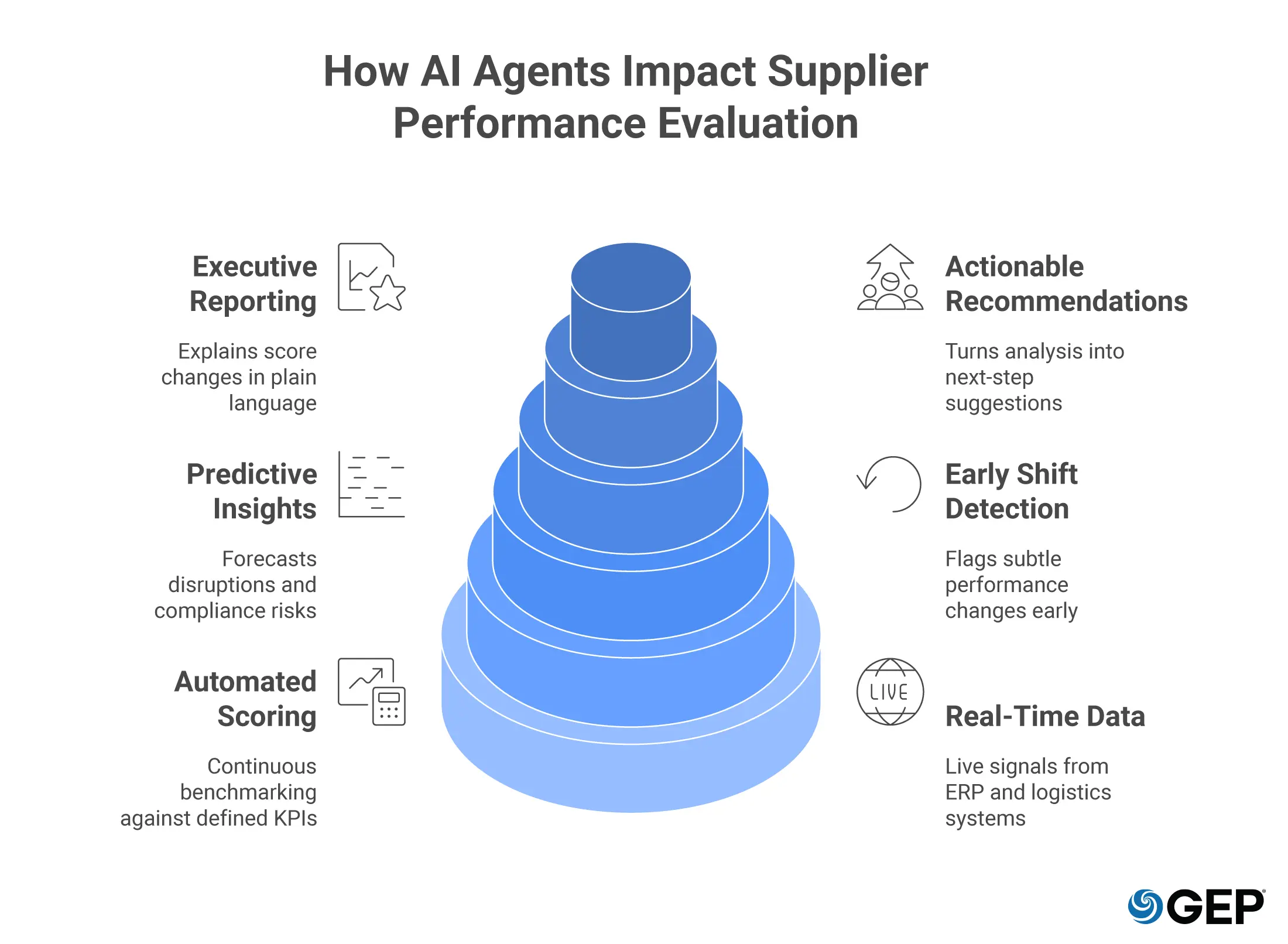

AI agents become a part of your procurement ecosystem. They pull data from ERP, logistics, finance, and quality systems, then piece it together like a live mosaic.

What used to take days of manual reconciliation now comes to you in minutes, clear and current.

Real-Time Data Aggregation

With AI agents, performance unfolds in real time. You don’t go looking for updates anymore; they find you. When a shipment runs late or costs differ from the original estimate, you see it immediately. High-impact issues trigger alerts, giving you time to act before they snowball.

Automated Scoring and Benchmarking

The agent compares every supplier against the KPIs you define and the benchmarks that matter. Scoring stays consistent and transparent. The agent evaluates and adjusts scores automatically as new data arrives.

Spotting Early Shifts

Early visibility gives you room to correct course while performance is still recoverable. You see the pattern early before it becomes a performance problem. When a metric drops below its target, or when a top performer has a change in behavior patterns, you’re notified immediately.

Predictive Insights

AI agents don’t just tell you what happened. They show what’s likely to happen next. They forecast disruptions, detect compliance risk, and surface warning signs tied to past trends.

Effective Recommendations

AI agents don’t stop at diagnosis; they turn data into direction, as they can also recommend practical next steps. You still make the final call, but you do it armed with context.

Executive reports

Generative AI-enabled agents can explain supplier score changes in plain English, supported by live data.

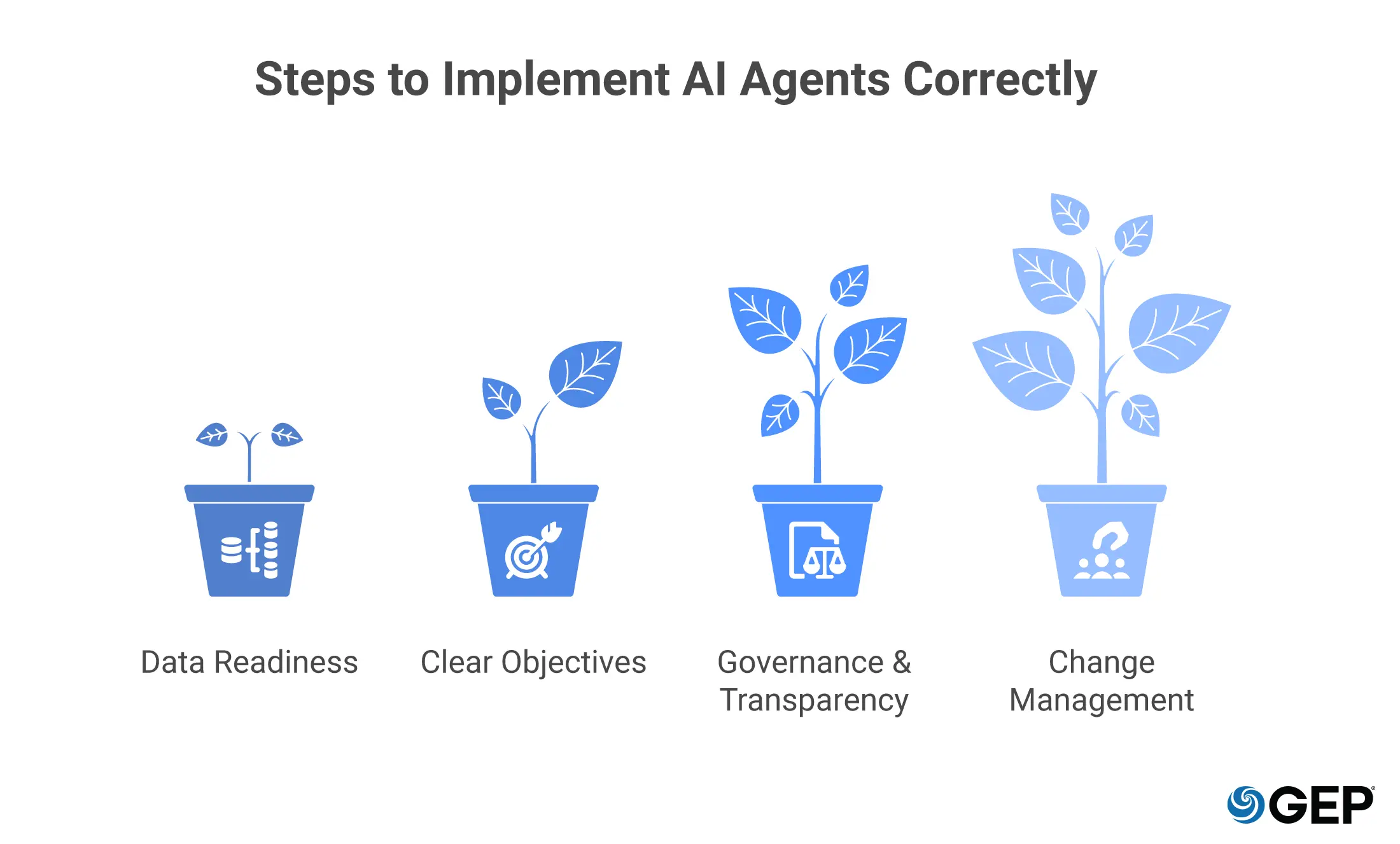

What It Takes to Implement AI Agents for Supplier Performance Evaluation

Build it as you would any strategic initiative: plan the phases, assign ownership, and review progress regularly. Here are a few key considerations during implementation.

Data Readiness

Every AI system lives or dies by its data. If records are messy, your insights will be too. Start with a data cleanup and standardize the data flows in and out of systems. Once the data speaks the same language, AI can make sense of it.

Clear Objectives

Before deployment, define what success looks like. Set your goals: faster evaluations, better risk detection, or stronger supplier relationships, and define how you’ll measure them.

Governance and Transparency

Supplier evaluation is a matter that requires high sensitivity. AI scoring must be fair, auditable, and accountable.

- Assign clear guardrails.

- Every action must be logged into the system to keep a clear line of sight for how decisions are made and who reviews them.

- High-stakes actions, like supplier removal or escalation, still need a human sign-off.

Change Management

It’s understood that introducing AI agents in procurement processes will change how people work. Involve teams early and help them understand what the system does and doesn't. Once teams see the value, adoption takes place naturally.

You don’t need to automate everything from day one. Start with one category, and scaling to the rest of your supply base becomes a practical next step. That focus keeps the rollout intentional and the results visible.

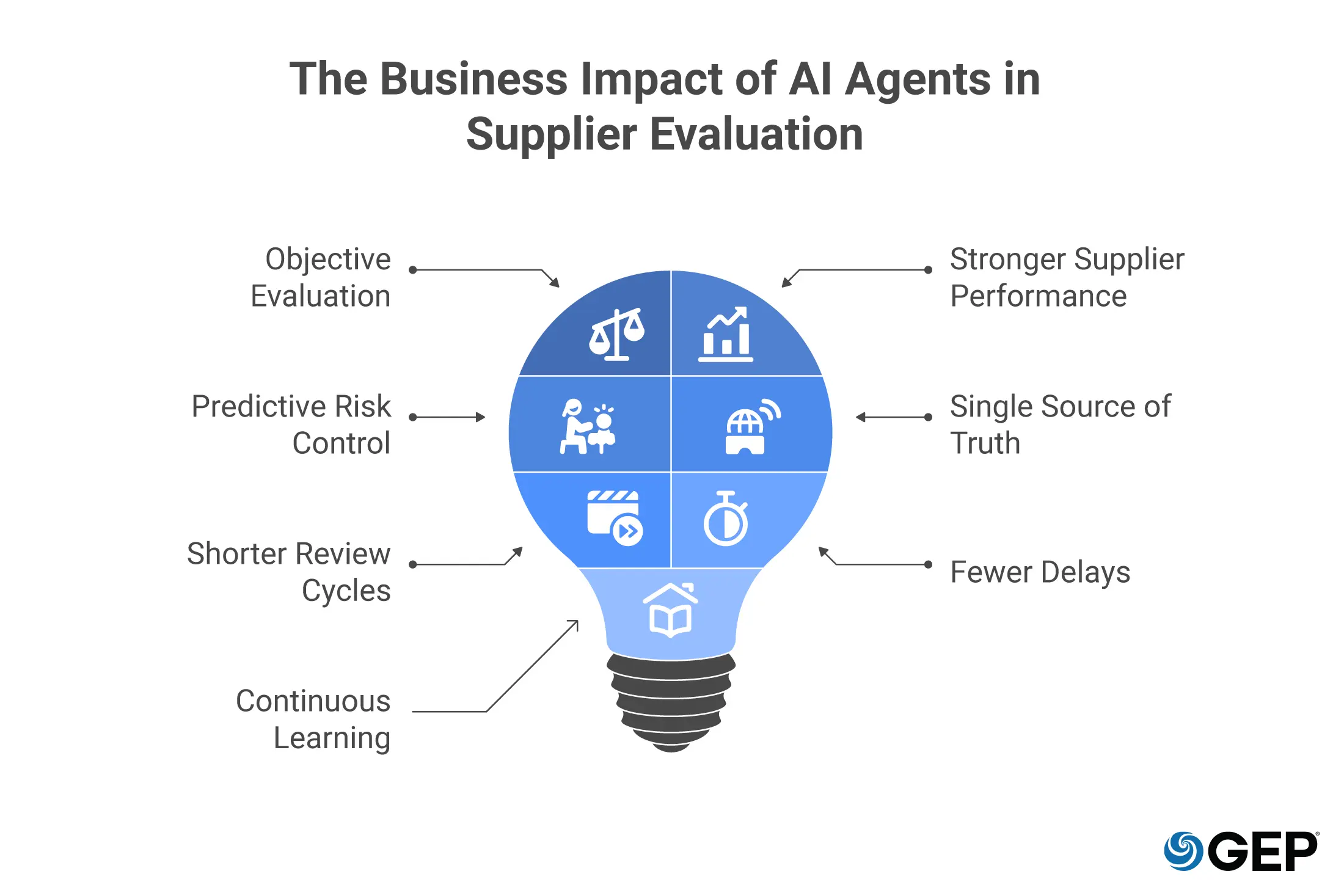

Benefits That Reshape Supplier Performance Management

AI agents turn supplier evaluation into a live process. You see changes as they happen. Issues are fixed faster, and reports stay relevant.

Fair and Objective Evaluation

Every supplier is scored the same way, giving teams consistent and transparent results every time.

Stronger Supplier Performance

Problems are handled before they spread, and consistent feedback drives better results. Suppliers hold up to quality, compliance, and delivery standards.

Predictive Risk Control

AI spots risks and estimates the likelihood of a cost jump or delay. Teams can act on them before disruption affects production or budgets.

Single Source of Truth

All supplier data lives in one unified dashboard. You can sort by category, region, or project. Everyone sees the same numbers and the same truth. And you can download sharable reports, making decisions move faster.

Shorter Review Cycles

Supplier reviews are continuous, with information updating automatically. Agents also escalate and follow up with humans in the loop, keeping things moving at all times.

Fewer Delays

Orders can be adjusted before delivery slows. Because you have complete process transparency, work always keeps moving, and suppliers stay responsive.

Continuous Learning

Each round of evaluation sharpens the next. AI learns supplier patterns and adjusts its scoring. Over time, evaluations become faster and more accurate.

These gains make supplier evaluation faster and more reliable. You move from looking back to staying ahead.

Managing Risks in AI-Driven Supplier Evaluation

Every system has its boundaries. Knowing where they lie and managing them deliberately is what keeps control in your hands, not the machine’s.

Data Quality and Bias

Good data keeps the system honest. Avoid bias in any form. When data inputs are messy, the AI results can be catastrophic.

Set clear standards, initiate automation of data verification at regular intervals, and ensure that major evaluations still undergo a quick human review. That habit keeps context in play and stops small errors from spreading.

Security and Privacy

Supplier information carries the weight of prices, contracts, and financial details that can’t leak. Protect it with encryption, limit who can see what, and keep a record of every access.

Overreliance and Trust

Having multiple agents validate each other’s findings and refine the evaluation autonomously can further help reduce errors.

Let agents flag what matters, but keep people in charge of important decisions. Review the system’s logic periodically and update it when business conditions shift.

Handled this way, AI becomes a reliable partner in supplier evaluation. It sharpens visibility and speed while leaving accountability where it belongs, with you and your team.

Turn Real-time Supplier Data into Actionable Insights

As visibility improves, control follows. Supplier performance evaluation by AI agents turns supplier data into something you can actually use: clear signals, faster reactions, and decisions grounded in facts.

The goal is to connect what you already have into a single, dynamic view in order to plan sourcing decisions strategically while being risk-averse. It’s the foundation that AI agents build on. The result?

You get live, reliable insights to make decisions with clarity at speed.

To make this easier, GEP SMART offers built-in tools for supplier performance management. The platform lets you create scorecards, track KPIs, and gather both quantitative data and qualitative feedback from across your supply base.

All performance information sits within a single supplier master record, giving you a consistent and current view of how every partner measures up.

FAQs

How do AI agents enhance supplier performance evaluation accuracy?

Most often, when supplier performance gets measured, the data doesn’t tell the full story. AI agents connect inputs from different systems and spot links that might go unnoticed. Each cycle improves their accuracy. Suppliers are measured by the same standards, so bias drops and results stay consistent. Evaluations become clear, factual, and easy to trust.

Can AI agents predict supplier performance issues?

They can. By comparing live data with past performance, AI agents identify early signals such as slower deliveries or small quality drops. These alerts appear before problems grow. You can act early, adjust with minimal effort, and keep operations stable.