Demand Forecasting with AI Agents: The Smarter Way to Plan Procurement

- AI agents make demand forecasting more accurate, timely, and risk-averse.

- Better forecasts improve lower holding costs, reduce stockouts or emergency buys, and free up working capital.

- Learn what agents do, how to implement them, and where teams see the most value.

November 20, 2025 | Procurement Software 7 minutes read

Forecasting often misses sudden shifts, and that costs you working capital and service levels. The problem is simple but costly. Volatile demand and fragmented data cause overstock in some SKUs and stockouts in others, and that drains cash and trust across supply chains.

Using an AI agent in demand forecasting gives you a different approach. AI agents pull in live data, flag anomalies, and update predictions without constant manual tuning, so decisions move from reactive to predictive.

This article covers how forecasting has evolved, the capabilities that matter to procurement, a practical five-step implementation path, common pitfalls, and measurable benefits.

Understanding The Shift to Agent-Driven Demand Forecasting

Forecasting started with spreadsheets and statistical models that used a narrow slice of history. Procurement teams used past sales as a proxy for future demand, and that approach breaks when markets move fast.

Next came basic automation, where machine learning and rules automated parts of the cycle but still relied on set parameters. Those solutions reduced manual work, yet they couldn't explain why a forecast changed or updated when external signals shifted suddenly.

AI agents change how procurement anticipates demand and reacts to market signals. They ingest sales, supplier performance, logistics events, macro indicators, and signals such as promotions or weather. They then adjust probabilities and recommended orders in near real time.

Today, demand forecasting in procurement has shifted from single-model, calendar-driven forecasts to continuous, context-aware signals that update and course-correct as conditions change.

Is Demand Volatility Slowing Your Procurement Team?

AI agents create steady signals that guide faster, sharper decisions

Talk to an Expert

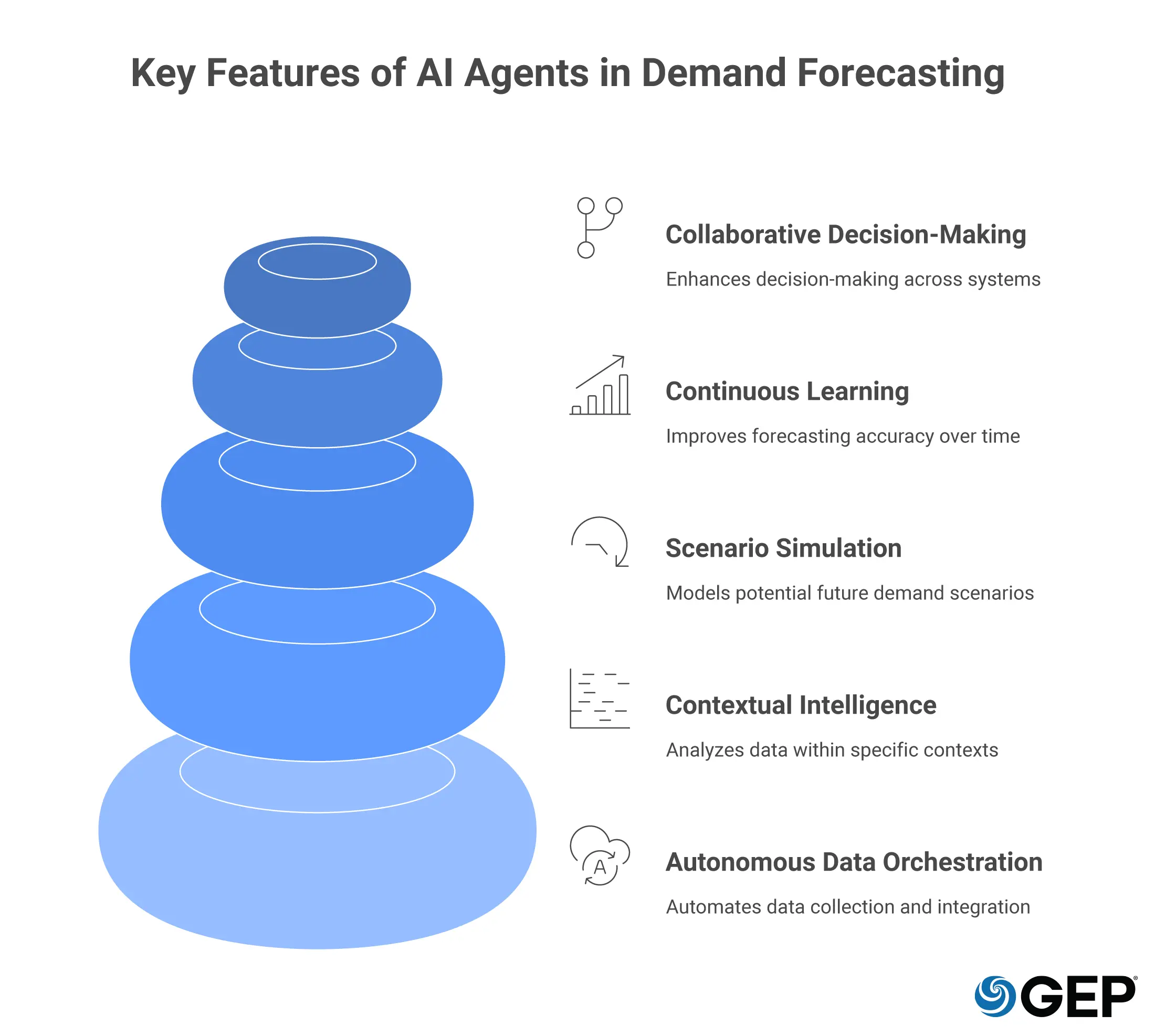

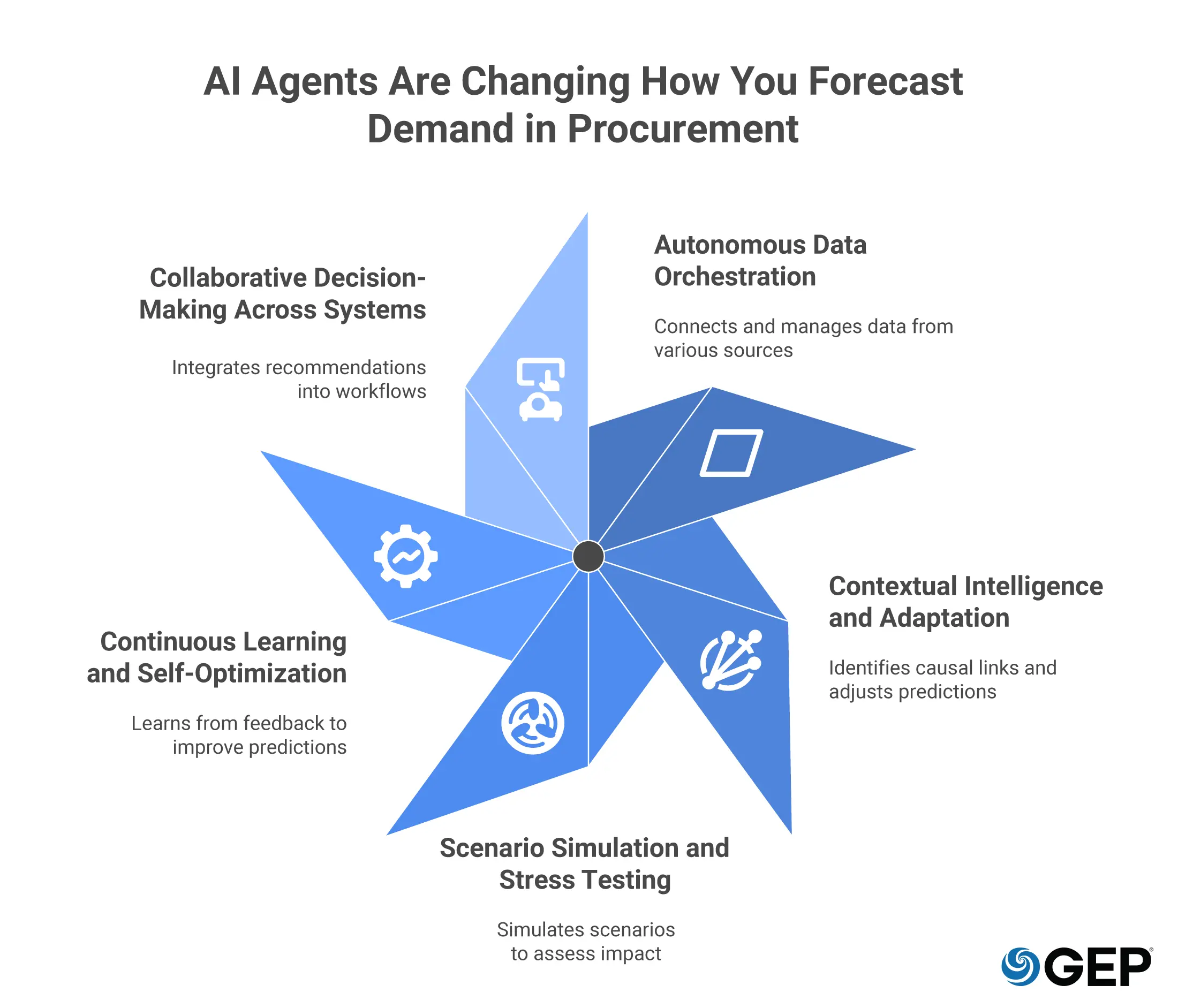

Key Capabilities of AI Agent-Driven Demand Forecasting in Procurement

Agents combine autonomy, context, and feedback loops to bring consistency and predictability that help procurement leaders make faster decisions in volatile markets.

Autonomous Data Orchestration

Start by connecting data from ERP systems, Customer Relationship Management (CRM) tools, and supplier portals so forecasts use full context. Agents map fields, normalize formats, and keep a live feed running. That removes the manual effort of merging reports every week.

Contextual Intelligence and Adaptation

AI agents identify causal links, such as shifts in customer behavior or supply shortages, and adjust predictions accordingly. Instead of treating a spike as noise, agents test causal hypotheses and weigh which signals should persist in the forecast.

Scenario Simulation and Stress Testing

Use simulations to see how a supply delay, a promotion, or a tariff change would move demand and cost. Agents can run multiple scenarios quickly so you can prioritize mitigation actions that protect service levels or reduce cost.

Continuous Learning and Self-Optimization

AI agents learn from each forecast, using feedback to tune future predictions and reduce manual retraining. That learning covers seasonality, promotion response, and supplier lead-time variability.

Collaborative Decision-Making Across Systems

Agents can push recommendations into procurement workflows and trigger actions in Robotic Process Automation (RPA) tools. When forecasts change, they can queue approval requests, update reorder points, or alert category managers.

Together, these capabilities make forecasting a live, decision-ready signal rather than a static report.

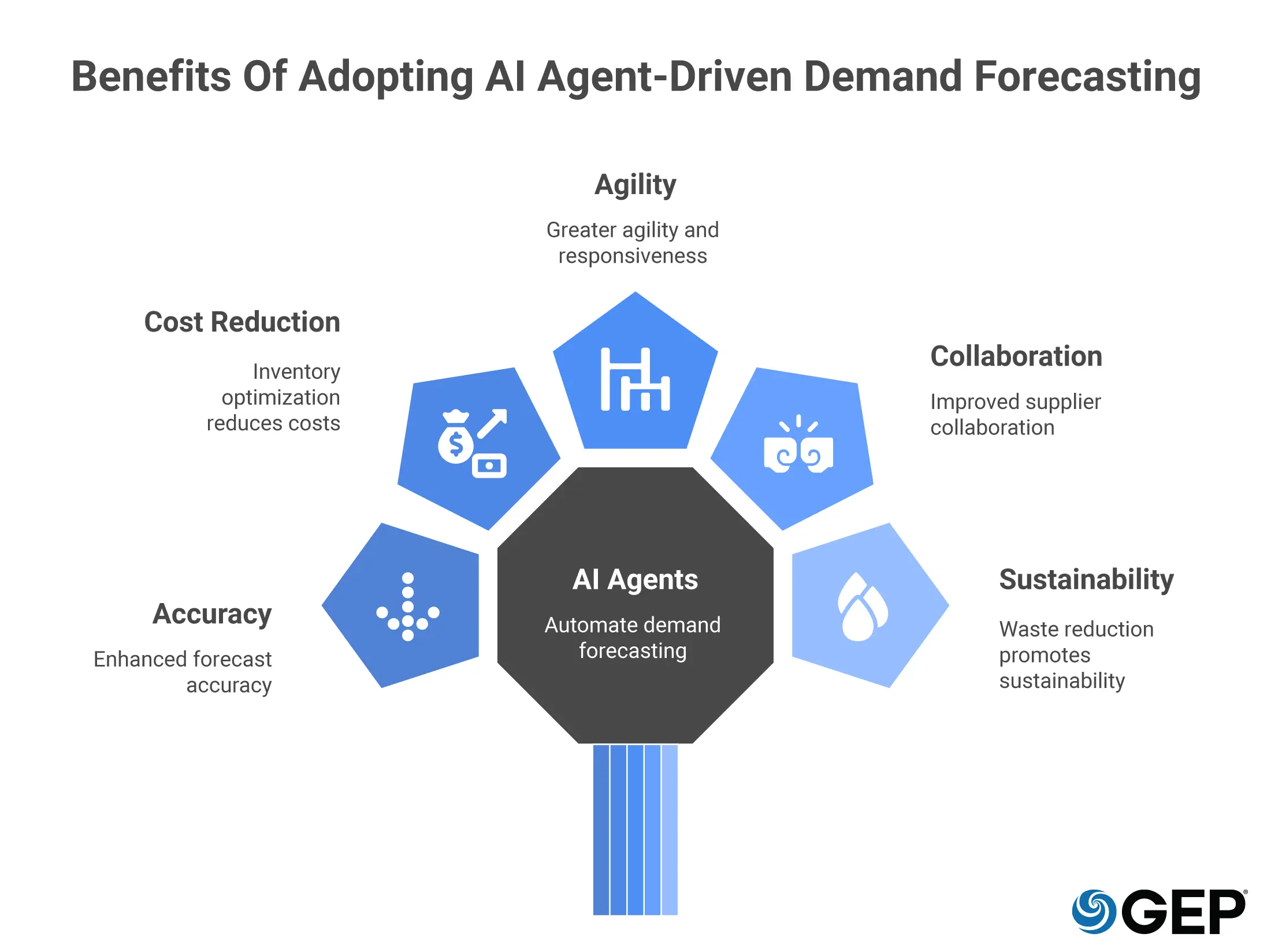

Benefits Of Adopting AI Agent-Driven Demand Forecasting

The practical benefits show up in inventory, cost, supplier performance, and sustainability.

Enhanced Forecast Accuracy

You’ll get narrower error bands because agents use more signals and update continuously. Improved accuracy means fewer emergency buys and more reliable fulfilment.

Cost Reduction via Inventory Optimization

Better forecasts let you hold less safety stock and avoid rush freight. That reduces holding costs and improves cash flow.

Greater Agility and Responsiveness

Agents detect shifts as they happen. You can reorder, reallocate, or pause production orders in near real time to match demand.

Improved Supplier Collaboration

When suppliers see accurate forward signals, they adjust production plans and reduce lead time variability. That creates steadier fills and fewer shortages.

Sustainability and Waste Reduction

Better planning cuts overproduction and needless logistics moves, which directly lowers emissions and waste.

These benefits compound as accuracy drives cost savings, which frees capital to invest in resilience and sustainability.

How To Successfully Implement AI Agents In Demand Forecasting

Agentic AI implementation succeeds only when you treat the project as people-plus-technology.

1. Data Readiness and Quality Control

Clean, consistent data from ERP systems, supplier portals, and logistics feeds gives agents the signals they need. Start with a source audit, fix high-impact fields like SKU mapping and lead times, and set up validation rules to catch feed errors.

2. Strong Governance and Ethical Oversight

Define rules that let agents act within clear limits and call for human review where decisions affect contracts or spend thresholds. Document decision rights and keep a change log for traceability.

3. Stakeholder Alignment and Change Management

Show fast wins. Run a focused pilot on a subset of SKUs or a single category. Share weekly dashboards that explain why forecasts moved so people can see the logic and outcomes.

4. Model Orchestration and Integration

Agents should plug into existing systems through APIs and work with Robotic Process Automation (RPA) where workflows exist. Don’t replace systems; augment them so procurement keeps known controls.

5. Continuous Feedback Loops and Performance Monitoring

Set accuracy targets and review them monthly. Use simple KPIs: forecast error, days of inventory, emergency purchase rate, and service level. Use those KPIs to tune model cadence and data sources.

Treat the rollout as continuous improvement. Start small, measure value, and expand once you’ve proven the approach.

Check Out GEP’s – Demand Planning and Forecasting Software

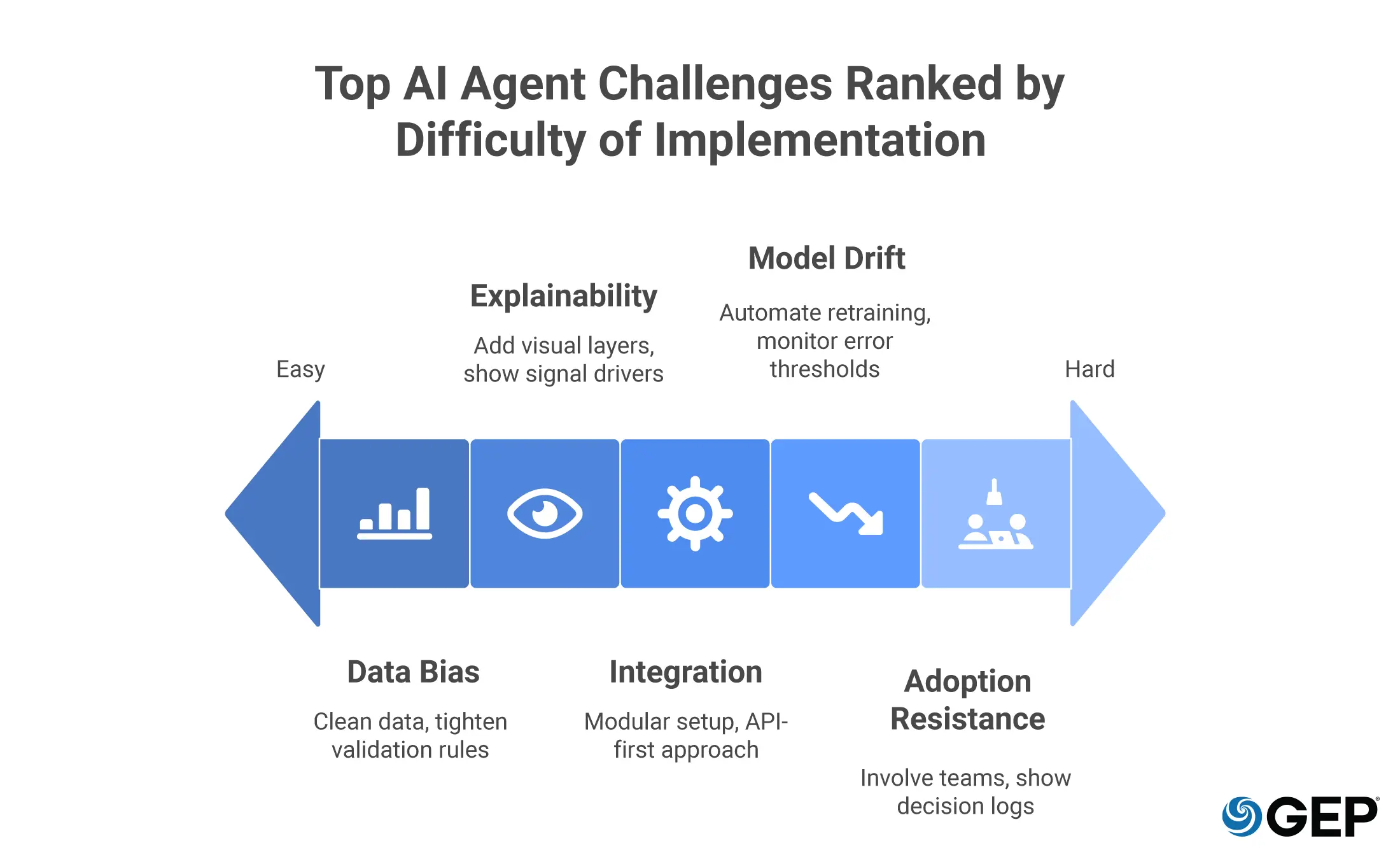

Common Challenges and How to Overcome Them

Agents aren’t magic. Expect data issues, integration friction, and adoption hurdles.

Data Bias and Quality Variability

Inconsistent feed structures or missing fields introduce noise. Fix the most critical data gaps first and apply validation rules that reject bad records before they reach agents.

Model Drift and Maintenance Complexity

As market conditions change, models may drift over time, especially if you aren’t continuously monitoring them. Solving this requires setting up retraining triggers, back-testing pipelines, and alert systems that flag drifts and keep a human in the loop for edge cases.

Cross-Functional Adoption Resistance

People resist what they don’t trust, and trust takes time. Teams often hesitate to trust agent recommendations. Use decision logs and short pilots to show cause-and-effect, and keep the team involved in threshold-setting.

Explainability and Interpretability

Provide explanation layers that show which signals drove a forecast change. Simple visualizations and event annotations go a long way in building trust.

Integration with Legacy Systems

Legacy ERPs and old interfaces slow you down. Use a modular, API-first approach and isolate data mapping from forecasting logic so you can swap components without breaking flows.

Always expect friction in your early pilots. Transparent metrics and small pilots reduce risk and speed adoption.

Data Center Expansion Needs Stronger Procurement

Learn how to stabilize supply lines in a market with fast-shifting demand

Access the Whitepaper

Practical Tips to Deploy an AI Agent for Demand Forecasting

Success is defined through well-planned pilots, data-backed outcomes, and how well people and the system work with each other.

1. Pilot Design and Success

Never chase scale before you prove value. Start where volatility hurts the most. It could be a specific product line or region where demand often swings.

Design a 12-week pilot on a high-variance category. Use a control group and measure improvements in error and emergency buys.

2. Define and Track Metrics

Use concrete metrics to prove impact early. Focus on:

- Forecast accuracy (MAPE): Shows whether the model tracks reality.

- Inventory turns: Reflects how fast stock moves through the system.

- Emergency purchase rate: Reveals reduced firefighting and better planning.

- Service level: Proves improved product availability.

3. Financial Impact Calculation

Translate improved turns into working capital freed. Even a one-day reduction in days of inventory creates measurable cash release on large catalogs. Use KPIs to make the business case and to scale the program responsibly.

4. Organizational Changes

Agents change routines. The people shifts are as important as the technical ones. Design work so your team focuses on high-value decisions. Plan training, role shifts, and governance.

- Change the Review Cadence: Move from monthly manual reconciliation to weekly exception reviews. Let agents run routine adjustments and reserve human attention for exceptions and strategic choices.

- Reskill People for Exception Management: Shift analysts from data assembly to exception diagnosis and supplier collaboration. Provide playbooks for common scenarios that agents flag.

- Align Incentive Structures: Reward improvements in forecast accuracy, reduced emergency purchases, and supplier responsiveness rather than raw order volume.

From here on, scale incrementally. Expand to adjacent categories, automate routine reorder decisions, and document every change to build a repeatable playbook.

Next Steps

AI agents in demand forecasting give you a live forecasting signal that sharpens decisions, lowers inventory, and speeds supplier alignment.

Start with a focused pilot, track forecast error and emergency buys, and scale where you see clear ROI. If you want to move faster, run a two-quarter pilot that integrates ERP, CRM, and supplier data, measure inventory and service changes, then expand.

Take the first step towards agent-driven procurement today. Explore GEP SMART™, a unified platform designed for enterprises that want to automate their Source-to-Pay cycle with intelligence, resilience, and measurable results. Built to handle disruption and market volatility, it gives procurement leaders better control over speed, accuracy, and spend visibility.

FAQ

AI agents improve accuracy by pulling in a wider set of real-time signals—supplier lead times, logistics updates, market movements, and even outside factors like weather or policy shifts. They keep learning after each cycle instead of relying on fixed assumptions. With every run, the system refines its weighting, trims errors, and brings the forecast closer to actual market behavior. With this, you recover more quickly from sudden market disruptions and gain greater supplier reliability.