5 Key RFX Types Driving Strategic Sourcing in Procurement

- RFX types are used to request supplier information, proposals, quotes, or solutions.

- Depending on the type of request, a specific RFX type is chosen.

- The Kraljic Matrix helps procurement teams choose between multiple RFX types.

September 04, 2025 | Procurement Software 10 minutes read

Choosing the RFx type might be the smallest step time wise, but it’s one of the biggest in terms of long term impact. Too often it’s rushed. Standard templates get dusted off, adjusted just enough to tick compliance boxes, and fired off. Fast, yes. Smart? Not really.

There’s no ‘one correct way’ of selecting an RFX. But owing to meeting faster sourcing cycles, most companies follow a generic method of choosing and creating RFX documents—and that’s where it all goes wrong.

When you get into a legal partnership with a supplier, you get into a long-term, multi-year liability. It would define your company’s quality, costs, and reputation down the line.

RFX is part of strategic sourcing. It's a formal document containing a set of questions to gauge a supplier’s capabilities, services, and learn whether they are a good match or not. But you won’t know a supplier's real value until you ask the right questions. And, an RFX does precisely that.

What is an RFx in Procurement?

RFX stands for "Request For X," where X is a placeholder for a particular request type.

Companies don’t really use “RFX”. They send out specific requests where “X” could mean asking for information, price quotes, detailed proposals, solutions, or formal bids.

An RFx is a straightforward, formal document that not only asks suppliers the right questions but also gives a quick snapshot of the buyer and the project’s needs.

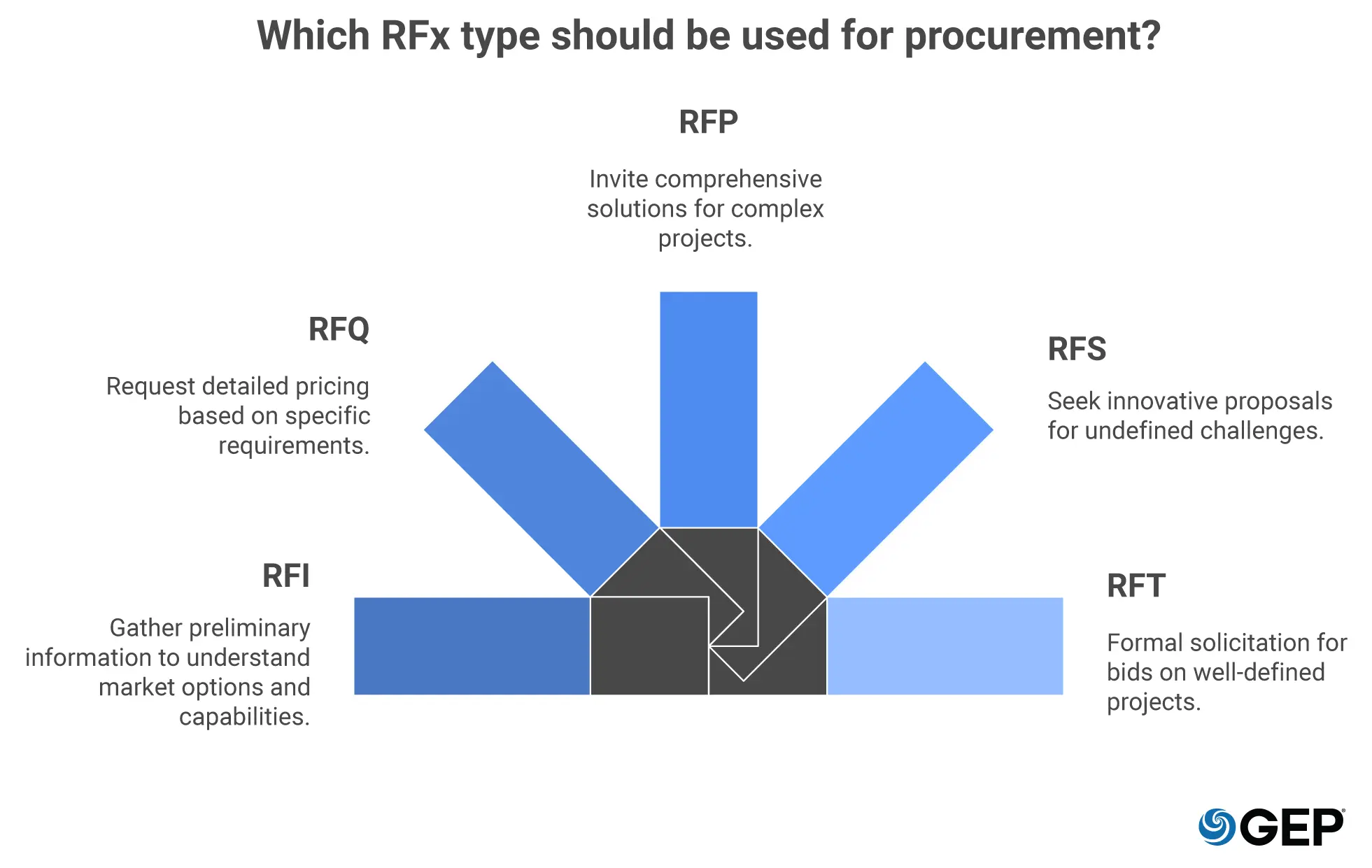

You’ll usually see these main RFx types in procurement:

- RFI: Request for Information

- RFQ: Request for Quotation

- RFP: Request for Proposal

- RFS: Request for Solution

- RFT: Request for Tender

Each has its own role, helping companies figure out which supplier can do the job, and do it well.

Talk to our experts

How Does an RFX Impact Procurement?

Before we get into the impact, let’s understand when an RFX is needed.

Procurement teams look for new suppliers when their existing suppliers underperform or a company expansion is in progress. However, moving away from suppliers is not easy.

Why? Because buyer-supplier relationships often stretch over years. They get tangled up in each other’s operations and depend on one another. Plus, many companies lean heavily on a few big suppliers to cover the bulk of their sourcing needs. That makes jumping ship even trickier.

That’s why picking the right supplier is more than a checkbox in your procurement process, but must be treated as a strategic move that shapes your business and reputation long-term.

Another critical aspect to consider is that the power dynamic between buyers and suppliers can directly affect procurement costs. When your goods are one-of-a-kind, fragile, need special handling, or suppliers are scarce against high demand, risks pile up, and costs follow suit.

So there you have it. RFX is core to how you choose suppliers, and that choice drives your costs and competitive edge. When you ask the right questions, you can look beyond straightforward things like supplier cost, size, timelines, etc., to more critical aspects like impact on sourcing strategy, supply vulnerability, and maximizing buying power.

What are the Different RFX Types in Procurement?

There are five main RFX types in procurement:

1. Request for Information (RFI)

You pull out an RFI when you’re in the “Let’s see what’s out there” phase. It’s like window shopping. You know you need something, but you’re not sure who sells the right fit or what the market looks like. At this stage, you’re fishing for supplier info – their products, costs, quality, capacity, lead times, materials, availability.

An RFI document usually gives the supplier a peek at who you are, then hits them with straightforward questions. The answers help you shape your sourcing strategy before you close on anything.

You (the buyer) may not have your exact sourcing requirements at this stage, but you still want to gather and compare supplier data and market insights to shape your procurement strategy.

2. Request for Quotation (RFQ)

This is where things get serious. You already know exactly what you need. And it’s now only about the price.

An RFQ (Request for Quote) is laser-focused on getting competitive pricing. No long backstories. No fluff. You send specs, timelines, and contract terms. Suppliers send back numbers.

An RFQ document usually includes a detailed overview of the buyer’s information, complete project specifications, phases and timelines, contract terms, submission deadline, evaluation criteria, and sometimes, weightage.

The beauty of an RFQ is in its uniformity. Every quote comes back in a format that makes comparisons fast and painless. It’s procurement’s version of lining products up side-by-side on Amazon and sorting by price.

3. Request for Proposal (RFP)

RFPs are used when a large undertaking requires a multi-stage, multi-factor solution.

Here, you aren’t just buying something off the shelf. You’re asking suppliers to pitch a full plan: technical approach, timelines, risks, compliance, staffing, and yes, pricing.

But pricing isn’t always the biggest factor here. Credibility, experience, value-adds, and reliability often outweigh a cheaper bid. What buyers want to know is the supplier’s potential in building reliable, long-term partnerships.

4. Request for Solution (RFS)

An RFS is what you send when you’re facing a problem with no clear playbook. You want creativity. You want disruption. You want a supplier to walk in and say, “Here’s how we’d solve it — and here’s why you’ve never tried this before.”

The RFS sets the stage for next level innovation. This is collaborative, high-value work.

An RFS has open-ended requirements and asks suppliers to come back with creative, holistic solutions.

Unlike an RFP, you’re not giving suppliers strict requirements to follow. You’re describing the challenge and inviting bold, strategic proposals often involving new tech or fresh methodologies.

The buyer’s goal here is not to receive a detailed solution, but an idea or overview of a solution that transforms existing processes.

5. Request for Tender (RFT)

Mostly used in government and public projects where fairness is critical.

An RFT is a formal, highly regulated bidding process for a well defined project. Compliance checks are thorough, and timelines are strict. There’s no room for creative deviations; the winner is the supplier who meets the exact brief at the best terms.

Accelerate Procurement with Agentic AI

See How AI Agents Plan and Act for Measurable Impact

How to Select the Right RFx Type?

In most procurement playbooks, the journey starts with an RFI. You dip your toes in the water, collect intel, then move on to an RFQ or RFP when you’re ready for numbers or detailed proposals.

In the public sector, RFTs are the bread and butter — strict, highly structured, by the book. And yes, real-life sourcing rarely fits in neat boxes. You’ll see overlaps and hybrids, like mixing an RFP with an RFS when the project demands both precision and creative reinvention.

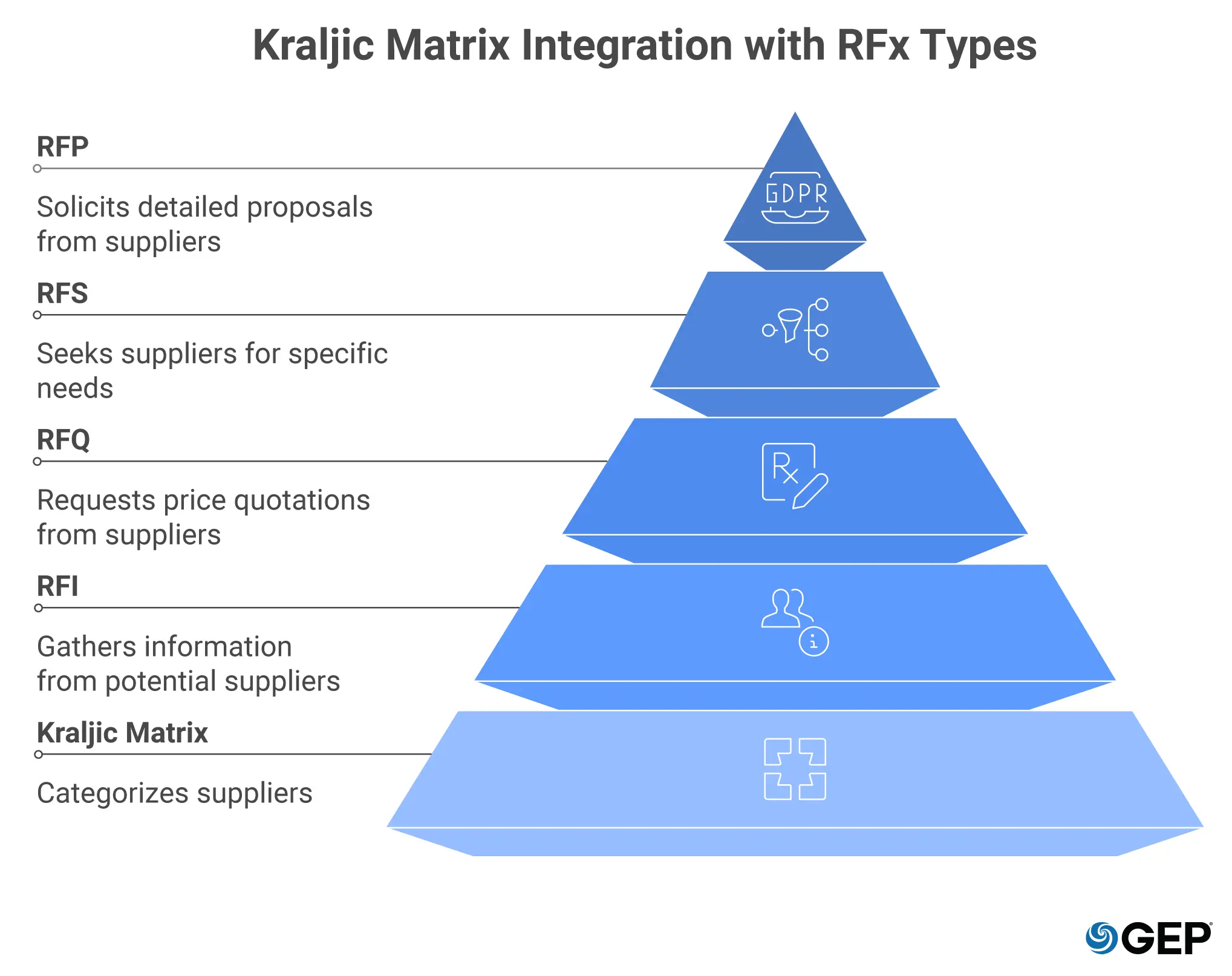

Now, here’s the truth nobody likes to hear: there is no “one magic RFx for every job.” Big, multi enterprise procurement teams know this. They lean on battle tested frameworks that have outlived trends. One model sits at the top of that pile: the Kraljic Matrix.

Peter Kraljic, then a Director at McKinsey & Company, dropped it in the pages of Harvard Business Review in 1983 — and more than forty years later, it’s still the backbone of strategic purchasing conversations. Analysts have poked at it, tweaked it, re drawn it, but the core idea still holds strong: match your sourcing strategy to the risk and the reward.

Here’s how it works.

Kraljic says every purchase sits somewhere along two sliding scales: profit impact and supply risk.

Put those together and you get four distinct quadrants — each with its own game plan:

- Strategic: Partner on critical, high risk, high impact items

- Leverage: Exploit buying power on low risk, high impact items

- Bottleneck: Secure supply for high risk, low impact items

- Routine: Streamline procurement for low risk, low impact items

Let’s break them down with a real world lens.

1. Strategic Items – High Risk, High Stakes

Problem: The supply of specific goods or services is critical to business operations and directly impacts profits.

What does it mean? These are the lifeblood buys. If you lose the supply, your operations stall, and your profits take the hit. To make matters worse, there may only be a handful of suppliers worldwide who can deliver. They know it. You know it. Prices stay firm.

Play it smart: Don’t nickel and dime. Build deep, strategic partnerships that protect supply while controlling cost.

RFx pick: Since very few suppliers in the market can meet your needs, you can rule out an RFI. When you know exactly what you need, go with a detailed RFP or — if innovation is still on the table — an RFS. And if you’re in government or a regulated environment, those same requirements might push you toward an RFT.

2. Bottleneck Products – High Risk, Lower Profit

Problem: Supply is disrupted when goods or services are unavailable due to limited availability or single-source suppliers for rare or specialized components.

These are the quirky components. The rare alloys. The one of a kind part that only two factories in Europe make (and one’s always on strike). Supply disruptions hit your workflow hard, even if the item itself doesn’t account for big profit margins. For continuous supply, keeping extra stock or entering into consigned stock agreements with suppliers may be necessary.

Play it smart: Secure alternatives wherever possible. Hunt for backup suppliers. Explore substitute materials or designs that still deliver the required performance.

RFx pick: Start with an RFI to identify who can actually get you the goods. Follow with an RFQ for pricing. Call in an RFP only if you need suppliers to propose alternative materials or designs.

3. Leverage Items – Low Risk, High Profit

Problem: The purchase price will ultimately define a large portion of the product's final price in the market.

Lots of options. Strong buying power. This is where a smart procurement pro plays hardball because pricing here can dramatically influence your final margins. Commodities often fall into this bucket.

Play it smart: Use competition to your advantage. Push for the best deal without cutting corners on quality.

RFx pick: An RFQ works perfectly here, or take it up a notch with a reverse auction to squeeze out the most competitive prices.

4. Routine Products – Low Risk, Low Profit

Problem: Inefficiency in procuring non-critical yet routine products that make up a small part of overall profits. Buyer-supplier interdependence is lowest in this quadrant.

Your office printer paper. Standard cleaning supplies. The kind of stuff nobody notices until it runs out — but replacing it should never eat up your brainpower or budget.

Play it smart: Keep it simple. Lock in bulk rates. Automate the re orders. A pool purchasing using e procurement or punch out catalogs.

RFx pick: A one time RFQ tied to a blanket agreement. That way, pricing stays fixed and you don’t have to keep going back to market for the same pen refills or janitorial chemicals.

Choosing the right RFx isn’t academic theory. It’s how you spend time and money wisely, without tripping over sourcing risks you could have spotted earlier.

The Kraljic Matrix gives you the map. The RFx type you choose is the vehicle. Pick wrong, and you’ll stall halfway. Pick right, and you’ll cruise through procurement with fewer blindsides.

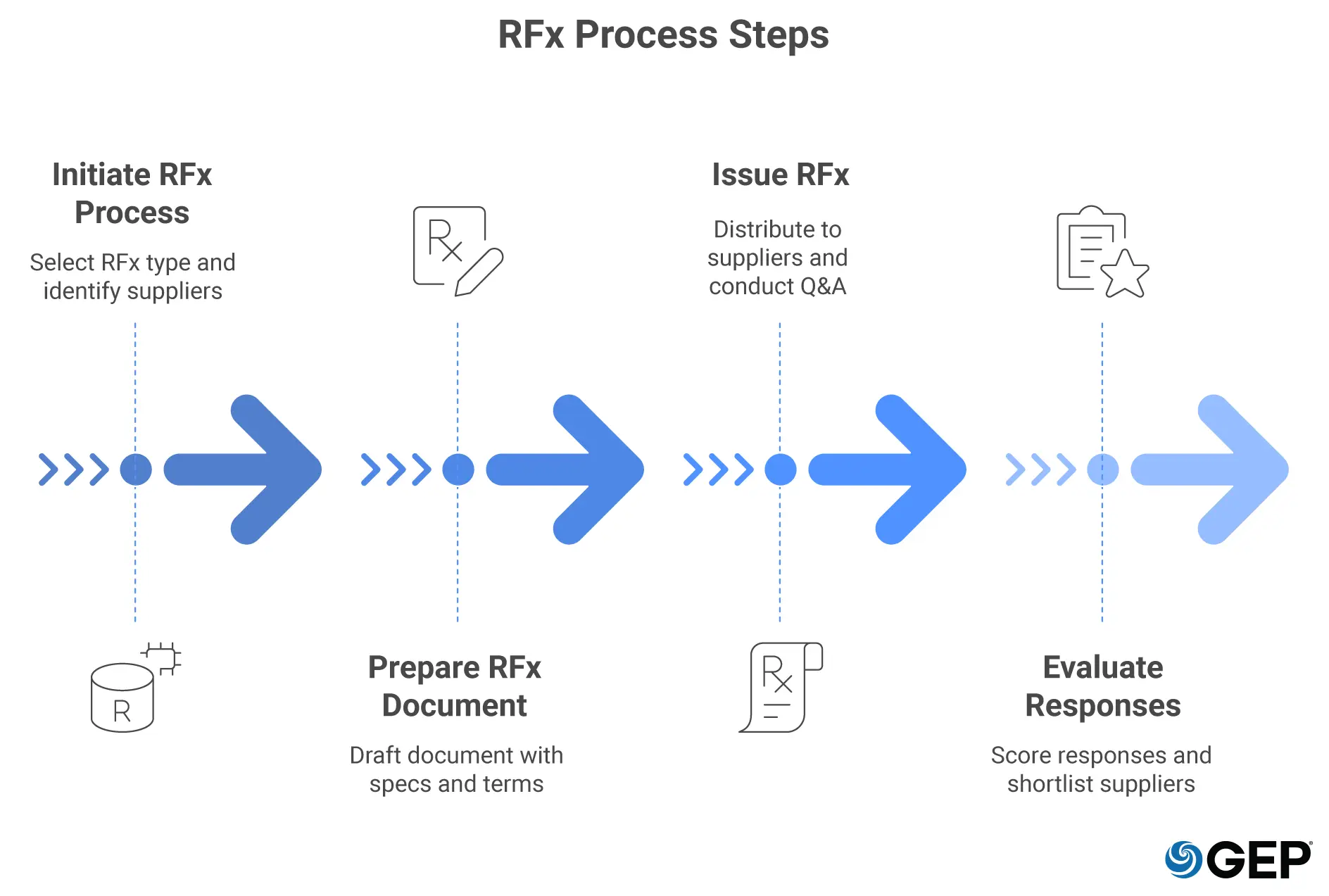

Steps Involved in the RFx Process

Getting an RFx right isn’t rocket science, but you can burn a lot of hours if you don’t keep it tight. Here’s the flow seasoned buyers swear by.

• Initiating the RFX Process

Pick the right RFx type for the job, then map out who’s in the running. This stage is all about clarity. The more certain you are here, the less backtracking you’ll do later.

• Prepare the RFX Document

Lay it all out — specs, scoring criteria, timelines, commercial and legal terms, submission instructions. And don’t forget one often missed ingredient: why a supplier should want to work with you. Good vendors have options.

• Issue the RFX

Distribute your RFx to the shortlisted suppliers, conduct Q&A sessions, and publish formal amendments.

• Evaluate Responses

Score the responses. Be consistent. Narrow down to the suppliers who tick the boxes and feel like a fit you can actually work with.

Best RFx Management Tips

These aren’t “best practices” because someone put them in a PowerPoint. They’re the things buyers learn after making a few mistakes and living to tell the tale.

1. Streamline the RFx Process

Use consistent templates and workflows to ensure fair supplier scoring and easily comparable responses.

2. Align Supplier Sourcing with Company Goals

Don’t force an RFQ on a project that really needs an RFP/RFS combo. Pull stakeholders in early. If you’ve got e sourcing tools that let reviewers score in real time, use them. They cut days off the cycle.

3. Establish Fair RFX Scoring

Whether it’s a spreadsheet or a procurement platform, define the scoring upfront and stick to it. Shifting criteria mid way tanks credibility.

4. Leverage Procurement Tools & AI Software

Modern procurement tools — think AI enabled sourcing platforms — can auto build RFx docs, flag supplier risks, and crunch data faster than you can open Excel. Just remember: tech helps, but you still make the calls.

5. Implement Supplier Self Service

Supplier self service portals mean fewer emails in your inbox. Vendors can download docs, upload responses, and manage Q&A.

6. Train, Test & Iterate

Train your team. Pilot new tools on low risk buys. After each cycle, gather feedback, tweak templates, and refine the approach.

The best RFx processes are built in iterations and are not locked on day one.

Conclusion

A clean RFx process does more than save time. While streamlining your RFX management process may seem small, its value compounds over time.

The right RFX choice shapes supplier relationships from the get-go and lays the groundwork for your entire procurement strategy. It can make all the difference between a deal that just gets done and one that delivers long term wins.

With the right strategy and an AI-driven platform like GEP SMART™, these early choices can lead to your biggest procurement wins.

FAQs

What is the RFx methodology?

RFx is an acronym for a whole family of procurement requests — RFI, RFQ, RFP, RFS, and RFT. The “x” just means it could be any of them. Each plays a different role, from gathering basic market info to locking down a formal deal. The idea is simple: get fair competition, compare suppliers on the same terms, and cut through the noise so you can pick the best fit without drowning in guesswork or paperwork.

What is the RFx phase?

It’s the starting block of the buying process. You define what’s needed, put it into a clear document, and send it to suppliers. That doc spells out scope, specs, deadlines, evaluation rules, and how to respond. Suppliers can ask questions before bids are due. This phase runs from drafting and issuing the RFx to collecting offers and doing the first round of comparisons—setting up everything that follows.