Decarbonizing Procurement: Cut Emissions Where They Begin

- Decarbonization starts when buyers establish a clear emissions baseline and responsible sourcing becomes non-negotiable.

- Focus on high-impact categories that can deliver the biggest payoffs.

- AI closes data gaps, models emissions, and guides procurement strategy.

December 10, 2025 | Procurement Software 7 minutes read

A routine purchase may seem harmless, but it can trigger real repercussions that you may never see. Materials are mined, fuels are burned, and waste is generated even before the product reaches the dock.

Each step releases emissions that accumulate over time, and they do not disappear. In nature, they come back as higher temperatures, disrupted harvests, unstable logistics networks, and compliance pressures. In procurement, these consequences return as delays, shortages, and unexpected costs.

Surely, there are ways to avoid these negative consequences. In fact, small steps in procurement can make a big impact in emission volumes.. A smart sourcing choice, for example, can reduce a supplier's energy use, shorten transport distances, and reduce waste.

Decarbonization in procurement tracks what goes on in the supply chain and manages it with intent. And for once, the outcome is one you control, not one that surprises you.

The Case for Decarbonizing Procurement

Decarbonizing procurement tackles problems that run deep within a supply chain. In many organizations, most emissions occur upstream with suppliers, making procurement a crucial lever in any net-zero strategy.

Research states that supply chain emissions often exceed operational emissions. This has a larger climate impact than internal changes alone. Smarter sourcing choices reduce lifecycle CO₂, cut waste, and shift entire categories toward cleaner production. This makes sustainable purchasing one of the strongest levers to reduce total GHG levels.

The business case is equally strong. Climate risks now shape profitability and compliance. Regulators demand clearer emissions data, especially for high-carbon materials. Boards and investors expect transparency and measurable progress. Procurement sits at the center of meeting all these expectations.

Scale Decarbonization with Precision

Target high-impact categories, build a clear baseline, and use AI to cut emissions across your value chain

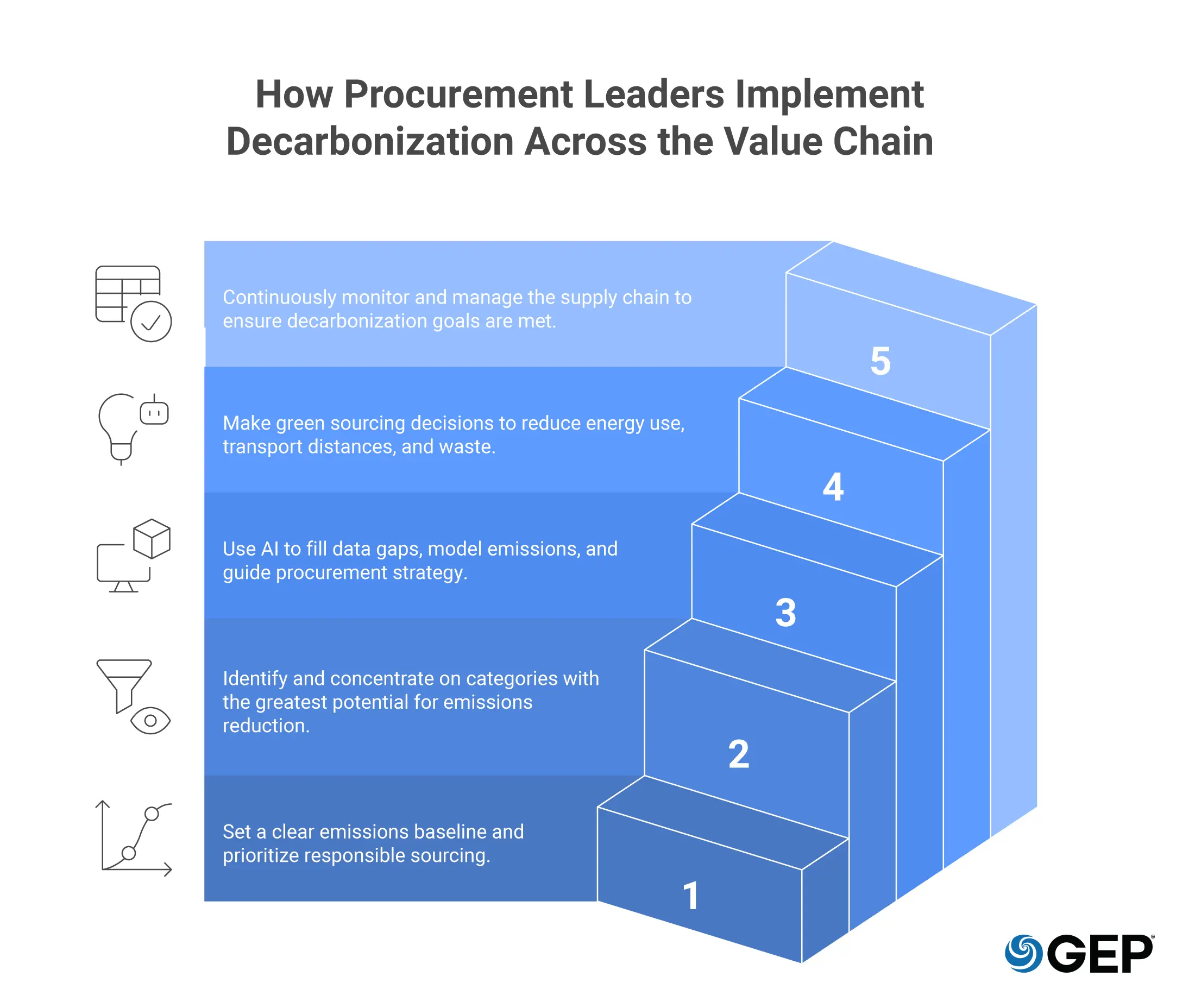

Five Steps That Guide Procurement Decarbonization

1. Build an Emissions Baseline

Every supply chain has a starting point, and for procurement, that point is the emissions baseline. Begin by gathering whatever energy and process data suppliers can provide and convert it into comparable carbon figures. When information is limited, use industry benchmarks to fill the gaps until reporting improves.

Once a baseline takes shape, emissions move from guesswork to something that can be managed with the same discipline as cost or quality.

2. Reward Conscious Sourcing

Even a small shift in evaluation criteria can reshape the emissions profile of an entire category. This changes the dynamics of how suppliers compete, and clear targets written into contracts carry those expectations upstream. With internal carbon prices and emissions-based scoring, award deals to suppliers who provide both financial and environmental impact.

3. Work Closely with Suppliers

Your decisions shape supplier decisions, and their choices shape your footprint. That is why supplier engagement matters. Offer training, tools, and guidance to help them measure and cut emissions reliably. Add sustainability clauses to contracts and request yearly reports to check progress.

Collaboration turns decarbonization from a top-down push into a shared effort. It also sends a clear message: improving the chain is a joint responsibility.

4. Use Incentives and Shared Rules to Shape Behavior

Market rules, industry coalitions, and financial incentives all influence how suppliers respond. Carbon pricing forces importers to disclose embedded emissions.

Set procurement standards to help suppliers know what the market wants. Offer sustainability-linked financing to those who show the best results on AI analytics and emissions calculators. These choices will continue to shape the broader chain.

5. Scale Decarbonization across Sourcing with AI

Leverage AI to get a clear view of your supply base and act before small issues become bigger problems. AI collects emissions data and fills weak spots. It also flags categories where the footprint is drifting off course.AI can model how a sourcing event shifts carbon emissions. It can rank suppliers by lifecycle impact and surface cleaner options you might miss in a manual review. AI agents handle reminders and report checks while flagging inconsistencies. That frees your team to spend more time on decisions and less time on chasing numbers.

Digital tools and smarter incentives, together with adaptable sourcing policies, ensure each sourcing choice nudges the chain in the direction you want.

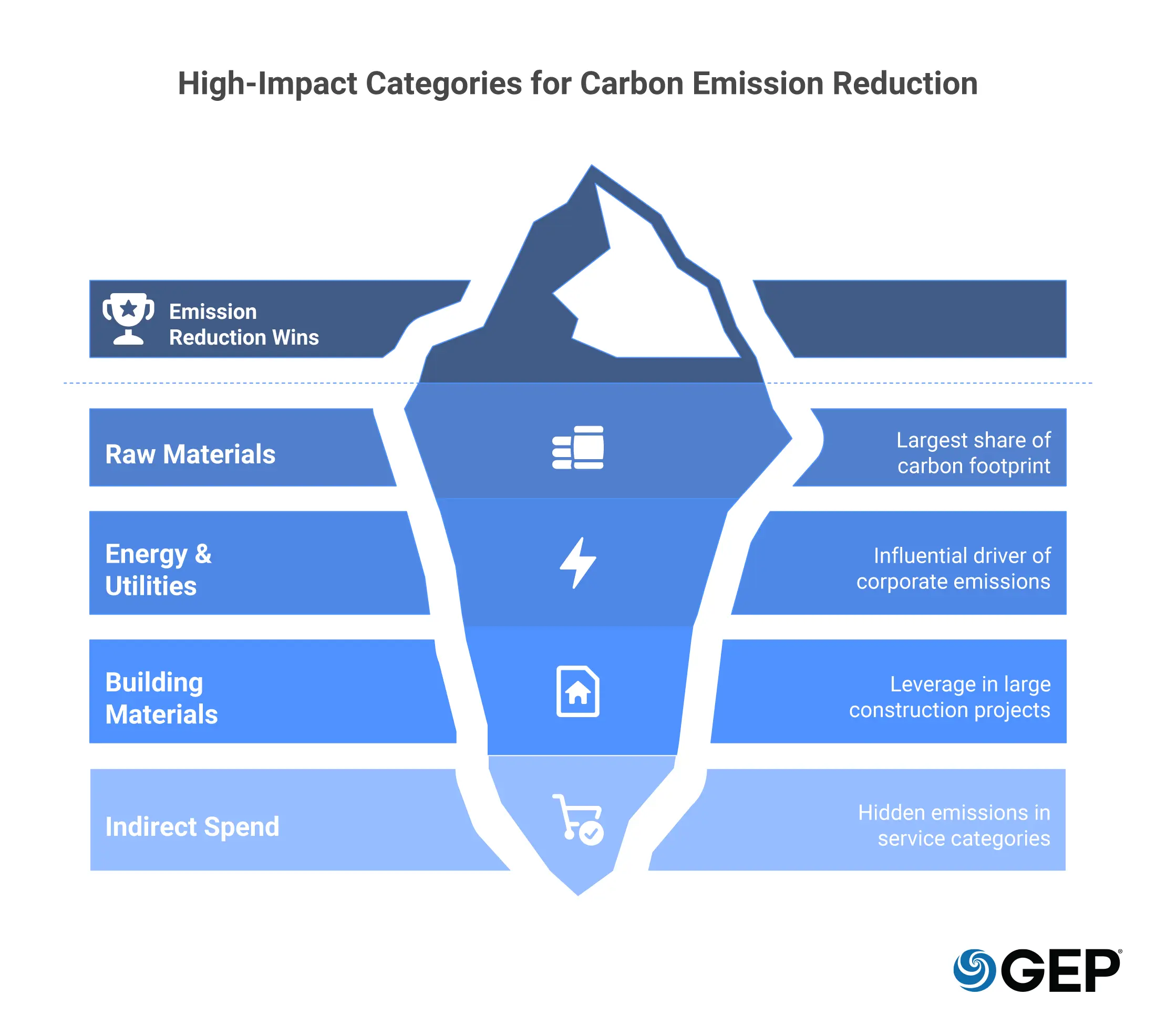

Five High-Impact Categories Deliver the Biggest Wins

1. Raw Materials and Manufacturing

Raw materials usually account for the largest share of your footprint. Steel, cement, plastics, chemicals, and timber all rely on heavy energy use. You can cut impact by choosing lower-carbon alternatives or by sourcing from suppliers that use cleaner production methods.

2. Energy and Utilities

Energy use remains one of the most influential drivers of corporate emissions. Long-term renewable power contracts now cover offices, manufacturing sites and data centers for many organizations. Others push suppliers to make similar shifts, extending the decarbonization pressure across the chain. Transport emissions sit close behind, accelerating adoption of electric fleets, efficiency upgrades and alternative fuels.

3. Buildings, Construction, and Infrastructure

Large projects give you a lot of leverage. Selecting low-carbon building materials or evaluating design options based on their emissions profile can shift the long-term impact. You can also choose office equipment and IT hardware with stronger energy performance when you rebuy assets.

4. Services and Indirect Spend

Indirect categories often hide more emissions than expected. Consulting, catering, travel, and facilities management all have embedded carbon emissions. Update travel policies that encourage employees to choose lower-carbon options. Or select recycled or remanufactured goods when they meet your quality needs.

5. Segment-Specific Opportunities

Each sector has its own levers. You might work with farmers in agriculture, packaging suppliers in consumer goods, or data center partners in tech. Look for places where a shift in buying behavior reduces emissions across the value chain. While most categories can support carbon-driven choices, you must first focus on the category with the strongest impact.

Are Your Logistics Emissions Growing Unchecked?

See how leaders use AI to make freight decisions and steer carriers with real-time intelligence

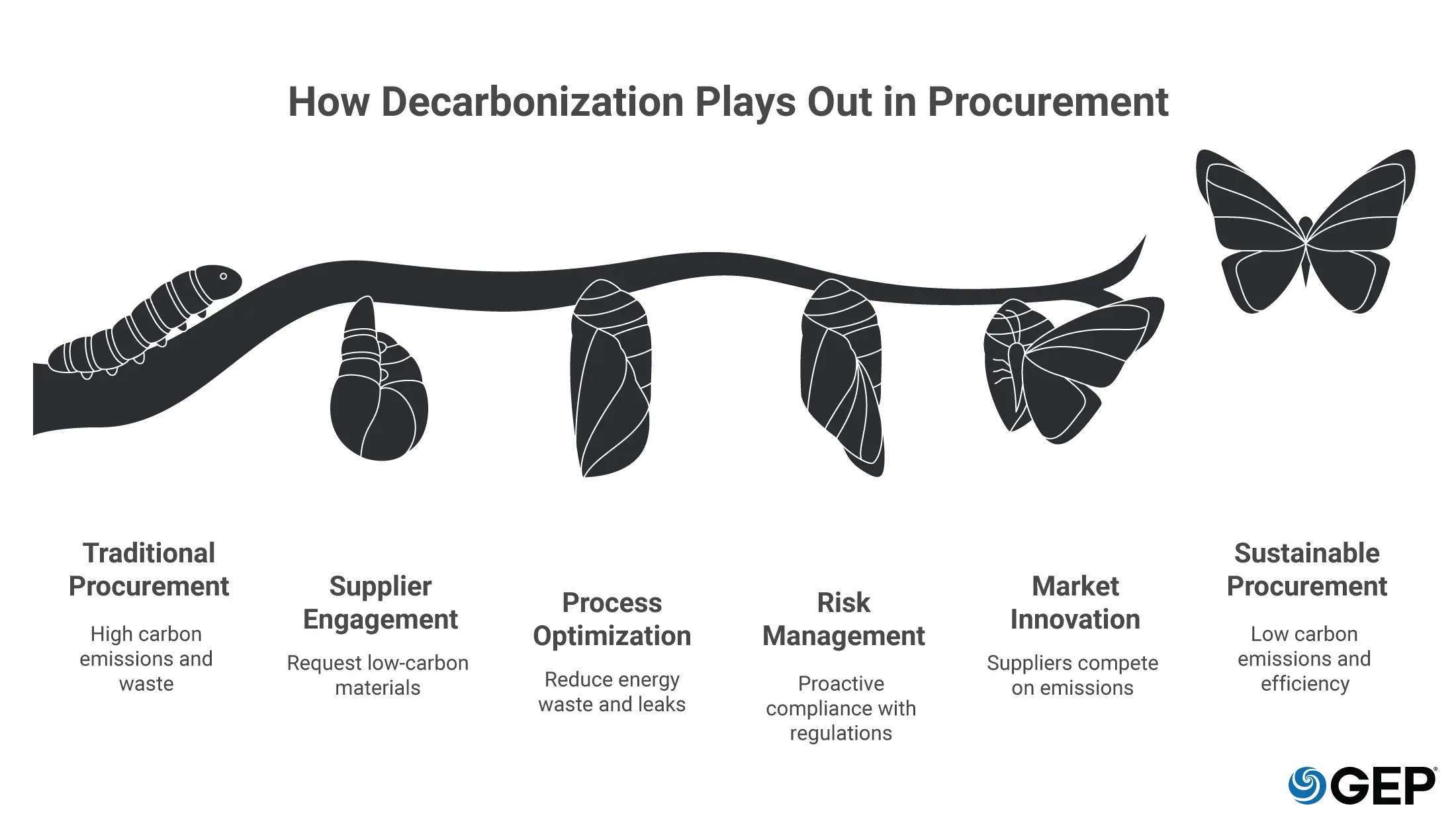

Benefits of Decarbonization in Procurement

• Stronger Climate Performance

You see the shift most clearly when you watch a category over a few cycles. As one supplier switches to cleaner power, another tightens a shipping route or redesigns a material with less carbon baked into it. Like this, the emissions curve starts to flatten, and the progress becomes visible proof that your actions are making impact.

• Financial and Operational Returns

The financial lift usually begins in small, quiet ways. A plant stops wasting energy, or a facility replaces equipment that has been dragging efficiency down. Processes that leak money and emissions are significantly reduced, and overall costs settle, while margins rise.

• Improved Risk Management and Compliance

You notice the value in being proactive when a new rule lands, and you are already ready for it. With the right implementation of AI and governance, you see how your suppliers have the data that regulators expect, and contracts contain the terms that matter.

You notice that your carbon footprint is headed in the right direction long before new compliance policies, tariffs, and disclosure demands hit.

• Market Growth and Innovation

Markets tend to shift when large buyers change how they move. While the first request for low-carbon materials piques supplier interest, the possibility of repeat demand forces them to share early alternatives. Before long, suppliers begin reworking production methods, testing cleaner inputs, and offering products designed to compete on both emissions as well as cost. When competition expands beyond price, entire categories start to move towards decarbonization.

• Better Access to Capital

Capital flows faster to companies that treat decarbonization as intrinsic to their procurement strategy. Investors respond when companies show up with real numbers, contracts, and reductions in working capital. With decarbonization, your ESG scores strengthen, giving you better offers and better terms.

Sustainability-linked financing becomes easier to secure because you can demonstrate year-over-year improvement.

Challenges You’ll Face and How to Overcome Them

• Data Gaps and Complexity

Supplier emissions data often arrives incomplete or outdated. You can start with reliable estimates and refine them as you get better reporting from suppliers. Each cycle strengthens accuracy and gives both sides a clearer baseline to work from.

• Investment and Scaling

Some early actions call for upfront spending. Focusing on areas with strong returns helps you show value quickly. You can also share the burden by offering pooled financing, shared training, or incentives tied to procurement goals, which allows suppliers to make changes without taking on too much risk.

• Supplier Readiness

Many suppliers, especially smaller ones, need help measuring or reducing emissions. Tools, templates, and simple reporting platforms make the process less intimidating. Phased timelines give them space to build capability while keeping the relationship steady.

• Internal Coordination

You get the best results when procurement, finance, operations, R&D, and sustainability teams work toward the same outcomes. Shared targets and clear decision paths reduce friction and keep choices aligned across the company.

• Regulatory and Market Changes

Rules and standards often evolve. Voluntary frameworks provide anchor points, and flexible sourcing policies make it easier to adjust without slowing operations. When you build for adaptability, shifts in the market or policy landscape create fewer surprises.

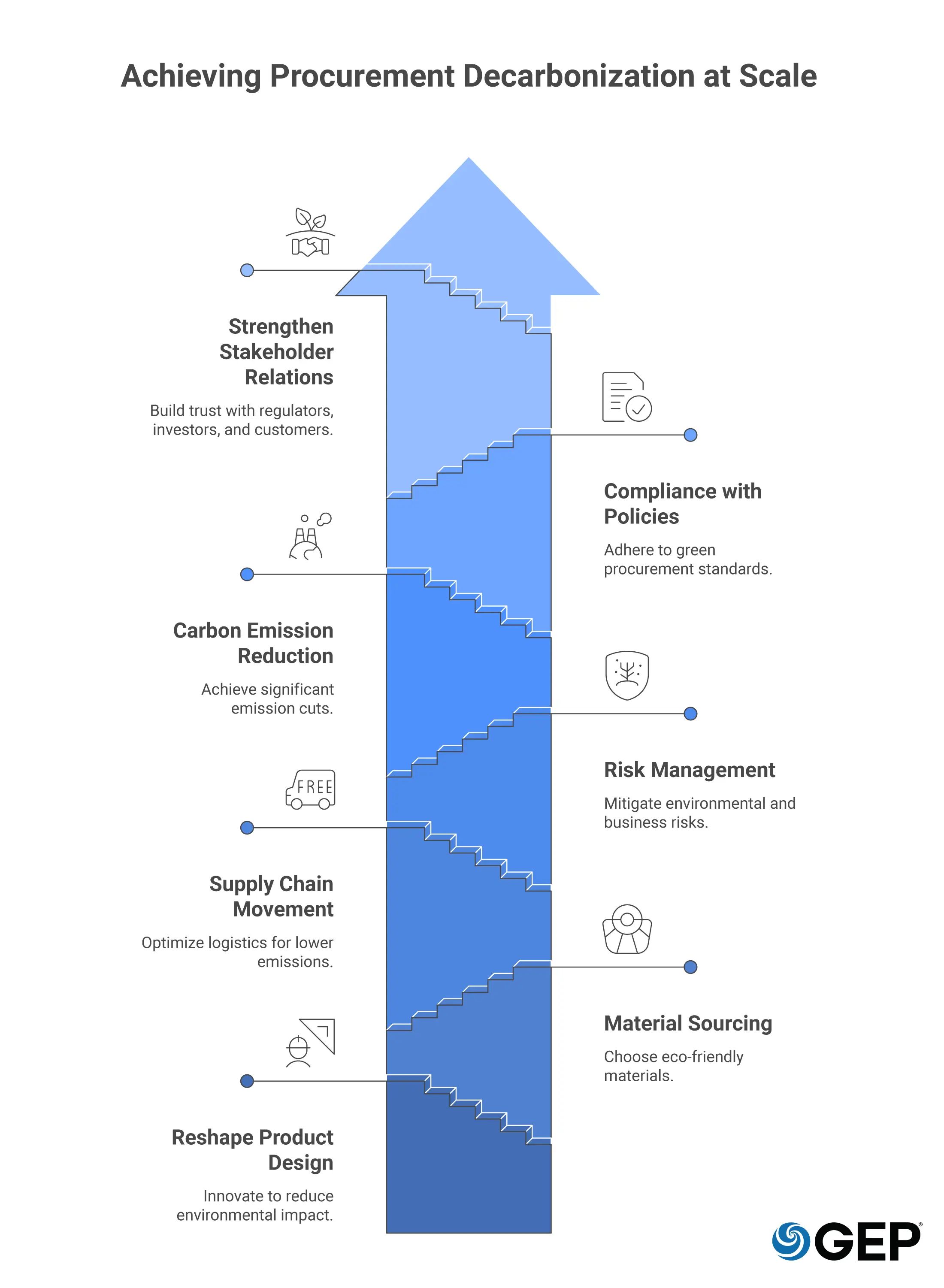

Your Path to Greener Procurement

Every sustainable decision you make reshapes product design, material sourcing, supply chain movement, and the risks that cycle back to your business.

The end output becomes one you control.

You also see the benefits where it counts: in carbon emission reduction and compliance with green procurement policies. With decarbonization, you also strengthen your standing with regulators, investors, and customers who want real progress, not empty promises.

Want to know how to use AI to scale decarbonization and streamline procurement? Make the first move with expert support from GEP’s Decarbonization Consulting Services.

FAQs

Scope 3 emissions cover building materials, food, travel, waste, and almost every purchased input you rely on. It’s the part of your footprint you rarely see, because these emissions live inside supplier processes and embedded materials rather than on your balance sheet.

Low-carbon procurement focuses on selecting lower-emission alternatives and working closely with suppliers to cut their impact. Many organizations now require suppliers to share basic carbon data during sourcing so you can quantify Scope 3 exposure and prioritize the categories with the biggest payoff.

Decarbonization pays off because lowering emissions helps suppliers reduce waste and energy use and eliminate inefficiencies. And as suppliers modernize and decarbonize their operations, they become less exposed to carbon pricing, fuel volatility, and regulatory fines.

Teams usually track total Scope 3 emissions, emissions intensity by category, and suppliers that provide verified carbon data. They also monitor the share of suppliers with science-based targets, the percentage of sourcing events that score carbon, and year-over-year reductions in high-impact categories.