Why Pharma Companies Need to Accelerate Digital Supply Chain Transformation Now

- The pharma sector’s supply chain lags in several metrics as compared to others.

- This sector faces immense pressure due to increasing regulation and lack of an agile, resilient supply chain and digital infrastructure

- Digital transformation and a unified supply chain platform can help create resilient supply chains to mitigate risk, optimize inventory, enhance collaboration and increase profitability

November 11, 2022 | Supply Chain Software 4 minutes read

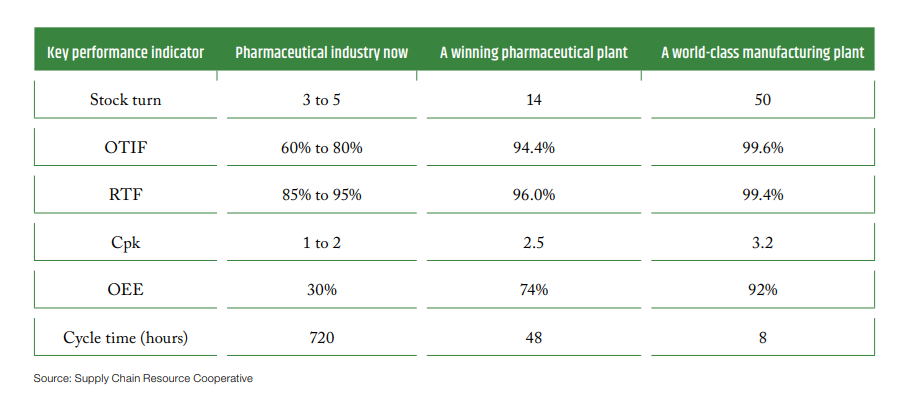

Despite being a trillion-dollar industry, the pharma supply chain is underperforming. The pandemic, skilled labor shortage and the absence of digital transformation have exposed the gaps in pharma supply chains, as is clear from the NC State’s Supply Chain Resource Cooperative data.

There is a lag in inventory turnover (Stock turn), inefficiency in meeting demands (OTIF) and the overall process capability and efficiency (Cpk) are way behind a world-class manufacturing plant.

Moreover, pharma supply chain executives feel the need for greater visibility, collaboration and control. For instance, they want to know where the shipment is and what’s its status in real time. They also need production forecasts and capacity information. Such data is often in paper or in Excel format – which is not easily available.

According to a survey conducted by the Supply Chain Resource Cooperative and North Carolina State University, 60% of these executives are dissatisfied with the timeliness of data and reporting around critical KPIs. They want more frequent reporting on active pharmaceutical ingredients (APIs), WIP goods and expiring inventory.

Pramod Sethumadhavan, Senior Director of Consulting at GEP, in a webcast with Pranav Padgaonkar, VP of Consulting at GEP points out lack of governance as another issue in pharma supply chains. According to him, even when there is visibility on these metrics, there is not enough governance to take that information and deep dive into the root cause of the issue and process it to mitigate those issues – both in the short-term and long-term.

Digital Transformation is the Need of the Hour

What pharma companies need now to create resilient and agile supply chains is digital transformation and a unified supply chain platform. Here’s how these additions can impact four critical challenges of pharmaceutical supply chains.

1. Limited Visibility into Risks

Pharma companies generally have suboptimal visibility into and collaboration with contract manufacturers, suppliers and distributors. They lack timely and accurate insight into consumer, partner, and market-by-market demand as well as external disruptions and their impact. Finally, they lack real-time visibility into inventory, including inbound and expiring inventory and the status of OTIF delivery to customers.

A unified supply chain platform provides real-time data and intelligence. Through a central control tower, it offers centralized, real-time visibility across the CMO, supplier and partner ecosystems. This includes integrating third-party data sources for better visibility into external events.

Moreover, it offers smart alerts to potential disruptions or issues and provides an understanding of the impact on operations and orders. It also offers recommendations for “next best actions” based on history and organizational standards.

2. API and Raw Material Costs and Availability

Availability and costs of APIs are major challenges for pharma companies. Lack of real-time data on API prices and availability causes companies to overstock. With a unified supply chain platform, pharma organizations can mitigate some of the impacts of API and raw material costs as well as price and availability volatility. It helps by leveraging demand sensing capabilities to apply data-driven insights from historical trends and market sources. This also helps in detecting events and conditions that might impact API and raw material prices and availability.

3. Ineffective collaboration

According to the Supply Chain Resource Cooperative at NCSU, the average pharmaceutical company works with 37 different CMOs and all CMOs generally need a network of hundreds of suppliers. The reliance on CMOs has increased multifold in recent years.

A shared platform for visibility and processes with contract manufacturers can help improve communication and collaboration in supply planning. Such a platform would allow contract manufacturers to share and react to forecast data and help users to view and analyze capacity of manufacturing/assembly lines across levels.

4. Offshoring

Transportation challenges to major markets and local bureaucracy have rendered offshoring a not-so-good idea. The pandemic-induced market and political demand for critical drugs and APIs has inclined CXOs toward nearshoring — the practice of transferring certain business operations, CMO and key supplier operations to major markets and nearby countries. Moreover, the shift from global supply chains to more self-sufficient regional supply chains has made nearshoring popular.

Deploying an advanced supply chain platform can enable businesses to accelerate nearshoring and tackle the challenges of collaborating with CMOs and key suppliers. The collaboration platform with AI capabilities can offer agility to unique operating environments and bring together different stakeholders. In other words, visibility, transparency and collaboration offered by supply chain platforms can ensure successful nearshoring.

Conclusion

To address current inefficiencies and adjust quickly in the new normal, pharma companies must create powerful and resilient supply chains. They must accelerate digital transformation initiatives and leverage a unified supply chain software. These measures can help them mitigate risks, optimize inventory, enhance visibility and supplier collaboration, increase profitability and allow for better governance.