Spending Too Much Time on Quality Audits? Get AI Agents to Monitor Supplier Quality in Procurement

- Recent research from Economist Impact shows that 60% of companies have either implemented AI agents for supplier performance monitoring or are actively evaluating them.

- Companies at the forefront of this shift use AI agents to handle repetitive quality verification tasks, which lets their procurement staff spend more time building partnerships with key suppliers.

- These systems track supplier performance data as it comes in, catching quality problems while they're still manageable rather than waiting until they've caused production delays or compliance violations.

December 09, 2025 | Procurement Software 5 minutes read

Somewhere right now, a procurement team is discovering a quality failure that their data predicted three weeks ago—if only someone had been watching. Instead, production halts while procurement scrambles to find alternatives, and costs spiral.

The most frustrating part? The warning signs were there all along, buried in inspection reports, audit findings and performance metrics that no one had time to connect.

AI agents offer a different approach. They run continuously, sifting through quality data and finding patterns that would take people weeks to notice. When procurement teams put these tools to work, they can head off quality problems before they turn into full-blown crises.

The Role of AI Agents in Supplier Quality Monitoring

While traditional automation systems follow preset rules, AI agents can observe, reason and adapt. They’re able to understand context and make decisions on their own, based on the parameters you give them.

These systems tap into multiple data streams: inspection reports, defect tracking, compliance audits, delivery records and financial indicators. They don't wait for scheduled reviews. Instead, they digest information as it arrives and keep a running assessment of each supplier's quality standing.

The real power is in pattern recognition. A human reviewer might notice that Supplier A's defect rate went up last month. An AI agent notices that Supplier A's defect rate has been climbing for six months, that similar patterns happened before other suppliers failed, and that this matches up with recent workforce changes at the supplier's facility. It connects dots that would take a person weeks to see.

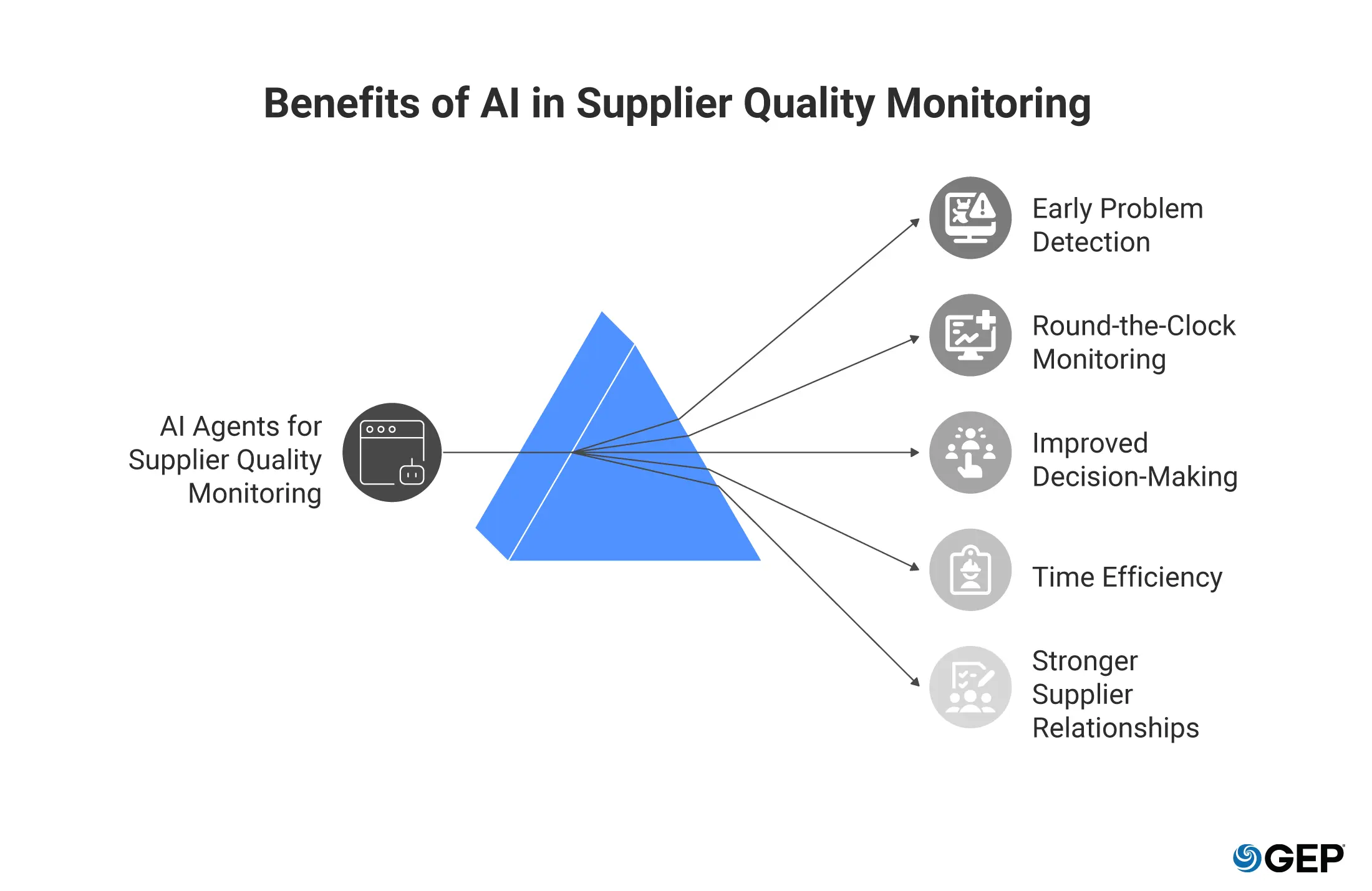

Key Benefits of AI Agents for Supplier Quality Monitoring

Catching problems early is the biggest win. Instead of finding quality issues when bad products show up, AI agents spot risks while you still have time to fix them.

Here's an example: An electronics manufacturer's AI agent notices that one supplier's non-conformance rates have ticked up slightly over three shipments. Not enough to set off alarms, but enough to suggest something's off. The agent flags it. The procurement team reaches out to the supplier and finds a calibration issue with their inspection equipment. They fix it before it becomes a real problem.

Round-the-clock monitoring means improved visibility into quality monitoring processes. When a supplier submits inspection data at midnight showing weird variation in critical specs, the agent catches it right away. When compliance documents expire, you get an instant alert.

Decision-making improves when AI agents analyze your quality data. A procurement manager looking at suppliers for a critical component needs to weigh defect rates, on-time delivery, compliance history, and audit scores across dozens of options. An AI agent analyzes everything in seconds and shows you what matters most.

More time for what matters is another big benefit. Instead of spending hours pulling quality metrics from different systems, your team can focus on partnering with suppliers and negotiating improvements.

Stronger supplier relationships grow from better conversations. When you approach a supplier with AI-generated insights instead of vague complaints, you can solve problems together instead of pointing fingers.

Check GEP’s- AI Powered Purchase Order Software

Overcoming Challenges in Supplier Quality Monitoring With AI

Quality information is usually fragmented across different systems: ERPs, quality management platforms, supplier portals, spreadsheets, etc. AI agents pull these pieces together into one clear view. But you need to invest in keeping your data clean and organized. Organizations that treat data seriously get much better results.

The shift from reacting to problems to preventing them fixes a major flaw in old approaches. AI agents use predictive analytics to spot risks before they turn into disasters. An agent might flag a supplier having financial trouble, knowing that money problems often lead to cut corners and quality issues. This heads-up gives you time to watch them more closely or line up backup suppliers.

Scaling up gets tougher as supplier networks grow. A team that can monitor 50 suppliers manually can't handle 500 the same way without increasing headcount. AI agents can apply the same standards whether you have one supplier or a thousand.

Limited team capacity holds back even the best procurement groups. AI agents handle routine monitoring and alert you to exceptions that need human judgment. This keeps people focused on complex decisions and strategy while machines handle repetitive tasks.

Future of AI Agents in Supplier Quality Monitoring

AI agents will keep getting smarter. Over the next couple of years, they'll get better at catching quality trends earlier. They'll work more smoothly across procurement, manufacturing and quality teams.

For routine purchases with clear quality standards, AI agents might eventually handle assessments on their own. They'll learn from experience and get more accurate over time. Different agents focused on quality, sustainability, risk and cost might work together to give you the full picture on suppliers.

But teams will still need to oversee complex, high-stakes decisions. Rolling this out takes time, so smart companies will do it in phases and learn as they go. Starting now gives you a head start over competitors who wait.

A Step Change in How Companies Monitor Supplier Quality

AI agents are enabling enterprises to move from firefighting supplier quality issues to actively preventing them. That means fewer disruptions, better supplier relationships and smarter use of your procurement team's time.

When AI agents handle continuous monitoring and pattern spotting, your team can focus on what they do best: building relationships, solving tough problems and driving strategy. If you're still managing supplier quality through periodic reviews and manual checks, you're falling behind. Start checking your data readiness now and building out a pilot program to come out ahead in the AI race.

FAQs

AI agents give you objective, data-backed feedback instead of vague complaints. This leads to productive problem-solving conversations based on real performance metrics instead of arguments.

Yes. AI agents spot early warning signs like rising defect rates, financial trouble, or process changes that often signal bigger problems ahead. This gives you time to step in before things go wrong.

AI agents monitor compliance requirements continuously. They flag expiring certifications, track audit findings, check documentation, and catch compliance gaps before they become regulatory problems or failed audits.