How Agentic AI Can Steer Electronics Industry Toward Green Procurement

- Choosing suppliers and components that lower environmental impact across the complete product life cycle.

- Treat sustainability and resilience as operational levers to balance carbon footprint, costs, and business continuity.

- AI in green procurement evaluates trade-offs across cost, lead time, and environmental impact at scale.

October 16, 2025 | Procurement Software 7 minutes read

Procurement in the electronics industry faces constant supply volatility that impacts product roadmaps. Component shortages, long lead times, and single-source critical parts leave you competing for speed, cost, and continuity.

Sustainability has now entered this equation as more than a compliance requirement.

Implementing artificial intelligence (AI) can help procurement teams turn resilience and sustainability into operational levers that keep production moving, even when supply chains remain volatile.

The US Global Electronics Council® has updated the EPEAT® criteria, making sustainable or green procurement more stringent in electronics sourcing. Set to take effect on November 1, 2025, the criteria raise standards around lifecycle, climate, circularity, chemicals, and responsible supply chains.

Procurement leaders need a practical way to cut energy use, increase recycled and renewable resources, and lower Life Cycle Assessment (LCA) emissions. This article gives you a realistic playbook on how to create and apply AI to green procurement in the electronics industry.

What is Green Procurement?

Green procurement entails choosing products and services whose complete lifecycle lowers the environmental burden while meeting functional requirements at acceptable costs.

Companies that follow sustainable procurement policies favor suppliers who can prove low-impact practices, recycled content, or clean energy use for manufacturing.

The primary levers of green procurement include sustainable sourcing of raw materials, designs for disassembly, supplier practices, and adherence to strict contract terms.

Procurement teams design contracts and product specifications that enable all the distinct levers of green procurement and use them to frame sourcing rules.

For instance, if your goal is to lower Scope 3 emissions, you focus on supplier emissions and materials. If you want circularity, prioritize take-back and recycled inputs.

Is Your Supply Chain Green Enough for 2025?

Know how to tackle Scope 3 data, supplier due diligence, and ESG compliance

Why Is AI Important in Green Procurement?

Your category teams can’t manually track tens of thousands of parts, sub-suppliers, and lifecycle emission sources. AI handles scale and complexity that humans cannot. It lets you analyze, simulate, and score across deep tiers.

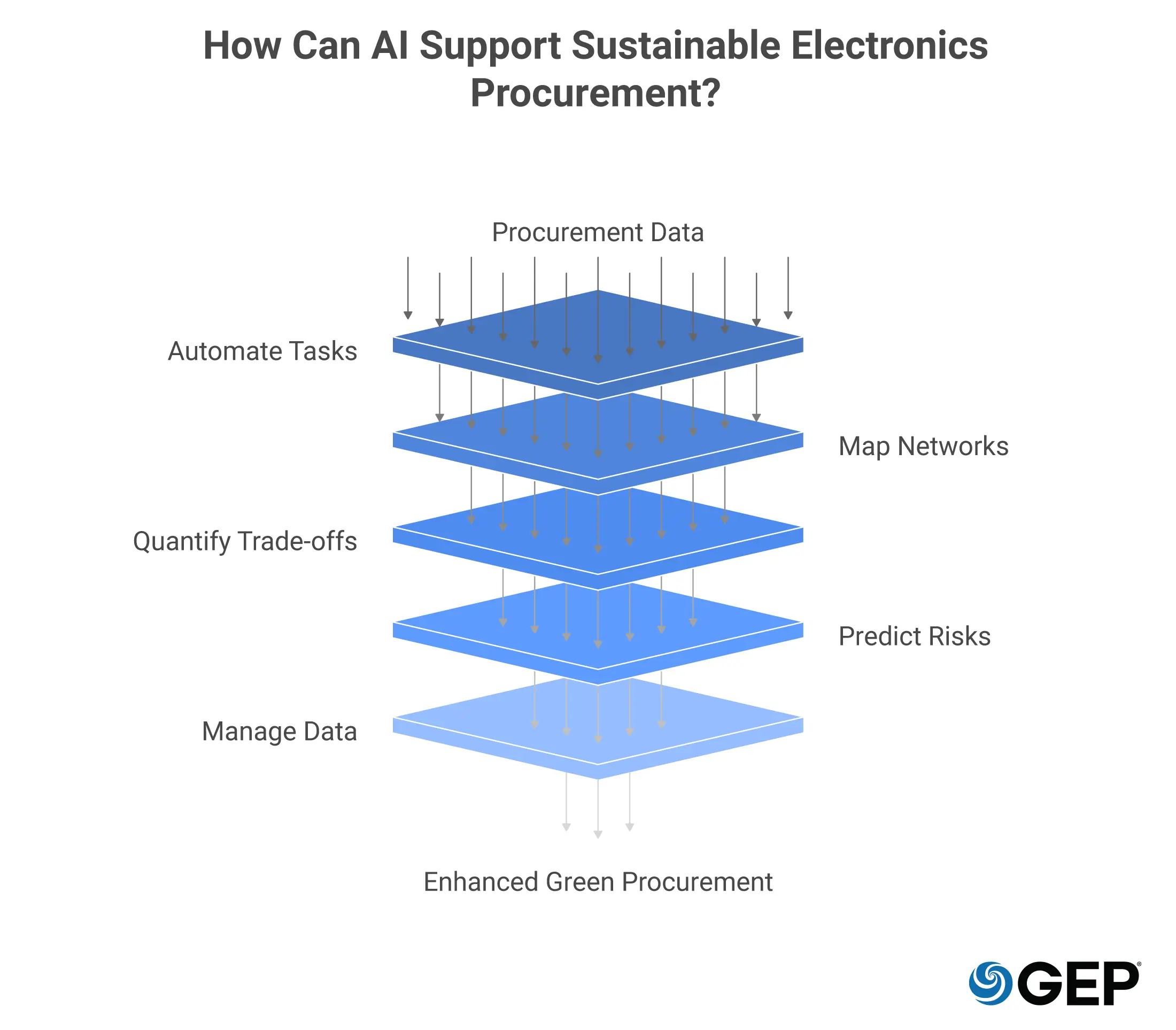

AI helps you do five things consistently:

- Automate repetitive tasks

- Map complex supplier networks

- Quantify comparative carbon and circularity trade-offs

- Predict supplier compliance or disruption risk

- Break down and manage complex data

Automate repetitive tasks that slow decision-making. For instance, AI automates the extraction of emissions data from supplier documents, normalizes energy intensity across component types, and flags inconsistent claims.

Natural language processing (NLP) extracts clauses from contracts and supplier reports, monitors compliance, and flags noncompliant terms. It also lets your procurement teams understand complex data by providing simpler context to enable faster, informed decision-making.

Prediction models process risks and surface viable low-impact alternatives before a crisis hits. They forecast material shortages, highlight regulatory changes, and identify supplier emission trends early so you can hedge, redesign, or re-source as needed.

When you ask AI to evaluate tradeoffs, it can show you the suppliers that minimize carbon per dollar or the substitution that preserves lead time with an acceptable carbon delta.

With AI, sourcing becomes continuous, evidence-based, and automated. It lowers cycle time and improves traceability without handing decisions to a black box.

Building Blocks of an Effective Green Procurement Strategy with Agentic AI

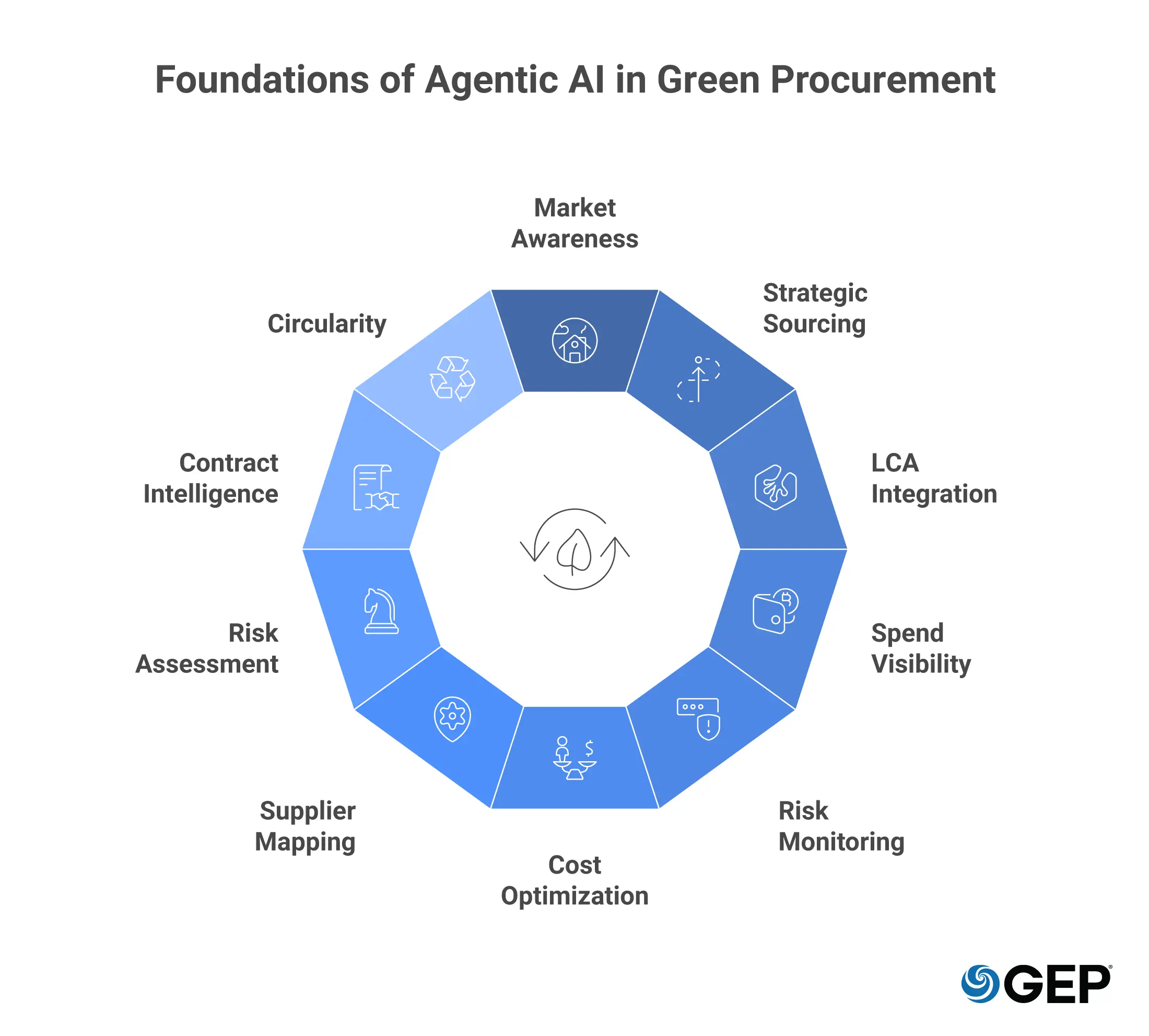

A robust green procurement category strategy combines data, models, suppliers, governance, and monitors the overall impact across KPIs. Agentic AI ties those parts into repeatable workflows. It treats each building block as a capability you can pilot and then scale.

Market Awareness and Forecasting

Keep a real-time read on commodity, regulatory, and supplier signals so you predict shortages and price moves. AI ingests market feeds to detect early signs of material stress or regulatory shifts. Agentic AI agents can run continuous scans and alert you when a signal crosses a risk threshold.

Strategic Sourcing and Greener Alternatives

Cost is just one aspect. Your sourcing strategy must also include material types, performance, quality, and carbon footprint. Models match technical specs to alternative parts and score them on emissions, material content, and cost. The output is a ranked shortlist you can test quickly.

Life Cycle Assessment (LCA) Integration

Make carbon and environmental impact a live input to sourcing decisions. AI accelerates LCA by estimating embodied energy and emissions from supplier inputs and manufacturing processes. With LCA data integrated into sourcing tools, you evaluate trade-offs at the line-item level.

Spend Visibility and Classification

Clean data is key. Machine learning classifies spends, tags categories, and links SKUs to technical families and material profiles, revealing hidden footprint hotspots and redundant buys.

Risk and Compliance Monitoring

Monitor supplier environmental, social, and governance (ESG) factors, sanctions, and standards continuously. AI agents check supplier audits, certifications, and regulatory lists in real time. Alerts allow you to act on supplier breaches before they cascade.

Cost Optimization Under Sustainability Constraints

Balance cost and carbon with optimization that respects constraints you set. You can set a maximum premium and let models find the best trade and propose bids or substitutions that meet cost bands.

Supplier Landscape Mapping (N-Tier Visibility)

Map suppliers who are not directly tied to your contracts with AI. They could be where risk and emissions concentrate. Graph analytics reveal common sub-suppliers, single points of failure, and recycled material flows, which helps you design mitigations and alternative routings.

Risk Assessment and Scenario Simulation

Stress-test your categories against “what-if” scenarios and prevent shocks against sudden policy changes. Agentic AI runs permutations and produces contingency plans.

Contract Intelligence and Clause Automation

Turn contract language into enforceable sourcing rules. NLP extracts warranty, material content, and sustainability clauses, and then tracks adherence. This lets procurement automate penalties, bonuses, or remediation steps.

Circularity and Reverse Logistics

Factor end-of-life costs and returns into purchase economics. AI models design take-back loops by predicting recovery values and logistics costs, so circular options compete on a total cost basis.

Poor green sourcing choices create immediate exposure. AI turns green procurement from a written policy into an operational capability you can scale.

AI agents can own separate functions end-to-end, while Agentic AI ties the blocks into workflow ownership.

How Can Procurement Leaders Implement It Correctly?

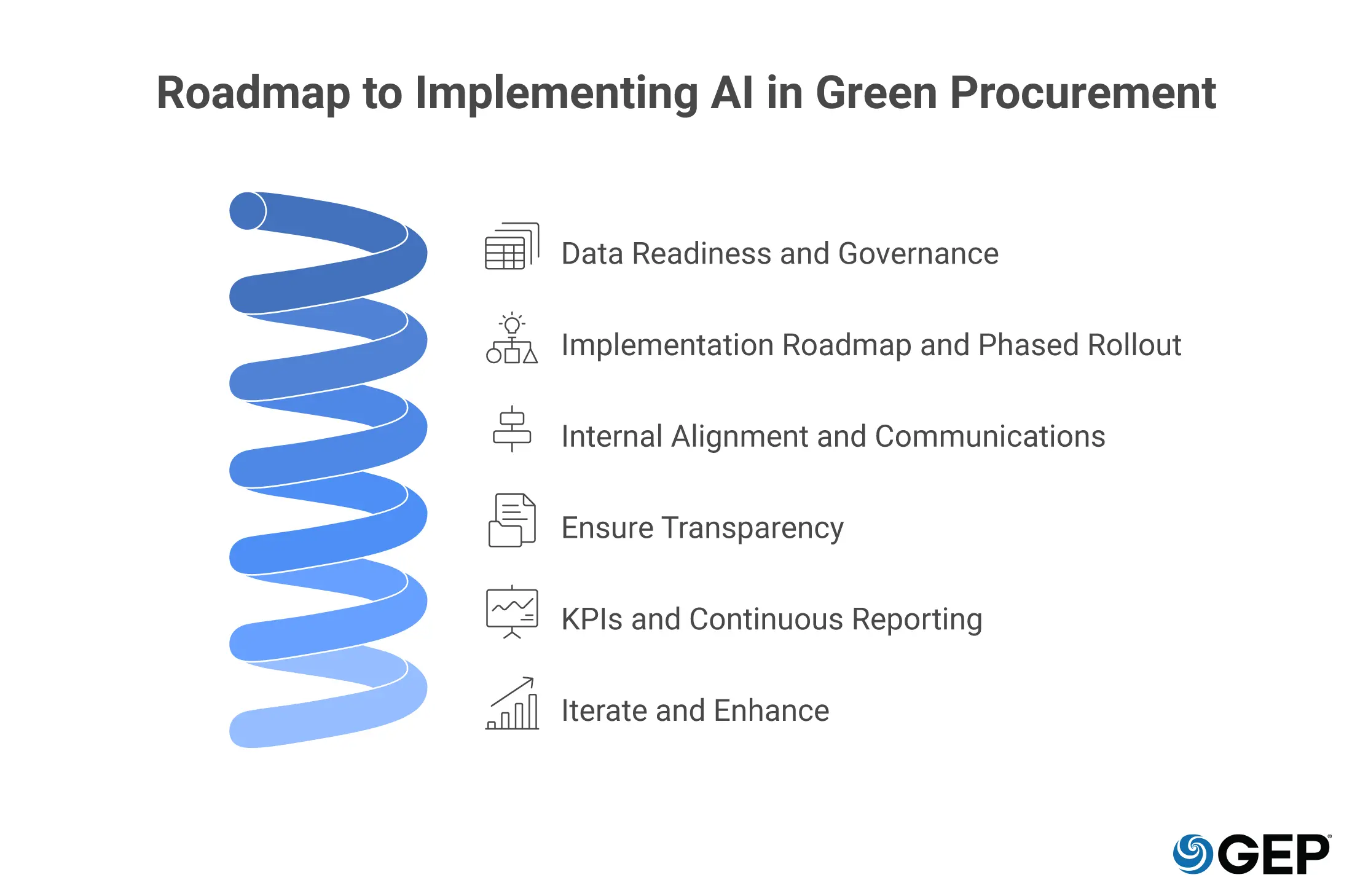

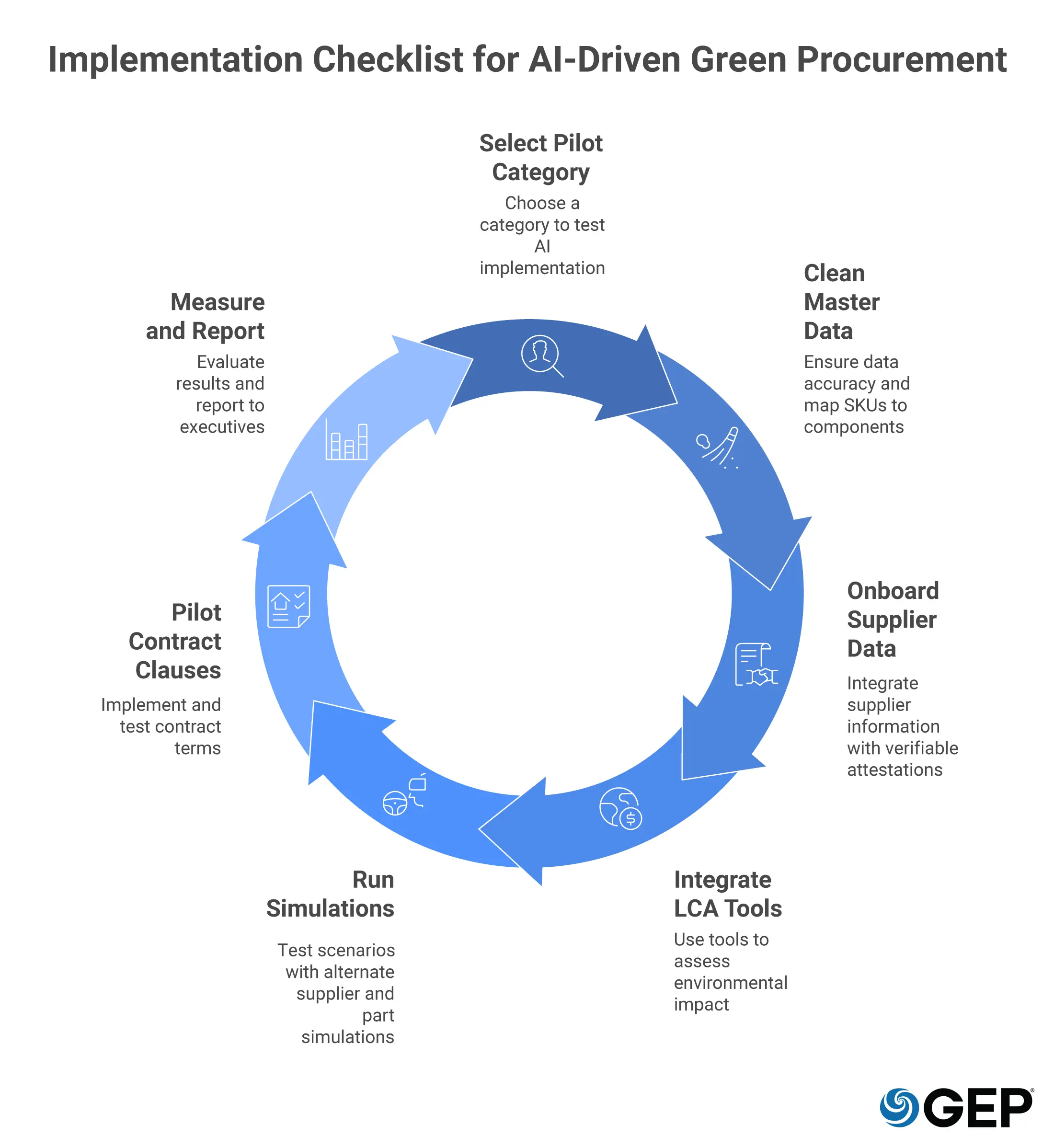

Plan your implementation with clear goals and a budget to create a roadmap for scaling. Pick a high-impact category and run a 90-day pilot. Here’s how to start:

Data Readiness and Governance

Trust the data feeding the models with lineage and verification. Use immutable logs, schema checks, and supplier attestations to ensure data quality. Without provenance, sustainability claims are weak. Use AI to clean spend, map suppliers, baseline emissions, and run alternate sourcing scenarios.

Implementation Roadmap and Phased Rollout

Use a capability map to prioritize what to build first. Plot impact versus ease of implementation, and start with categories that deliver emissions reduction and supply continuity. AI can automate repetitive tasks during rollout, so the team focuses on change management.

Internal Alignment and Communications

Maintain human-in-the-loop controls and audit trails. Build a cross-functional squad and give it clear authority and feedback loops. Include procurement, sustainability, engineering, IT, and legal, so decisions are implementable and auditable. Translate technical output into business stories for leaders.

Ensure Transparency

Automated narrative dashboards summarize what changed, why it matters, and what decisions the executive team must make. That reduces friction across procurement, engineering, and sustainability.

KPIs and Continuous Reporting

Translate outcomes into KPIs tied to business value. Tie pilots to measurable KPIs, such as a percentage reduction in carbon intensity or fewer expedited events. Over time, track carbon per spend, percent sustainably sourced, supplier performance trends, and avoided risk events. Agentic agents can refresh those KPIs automatically.

Iterate and Enhance

Let AI propose and automate low-risk actions while routing final technical approvals to engineers and contractual approvals to legal. Keep model logs and version controls so you can explain any recommendation.

Budget and talent matter, but so does patience. Expect early false starts. Validate models against actual supplier data and adjust incentives, not just demands. Pilot quickly, protect continuity, and expand capabilities based on ROI.

Are You Ready for AI-Driven Sustainability?

More than 70% of firms say AI helps cut carbon, but data and skills remain barriers. See what leaders are doing.

Common Challenges of AI in Green Procurement

Data quality, supplier transparency, internal resistance, and trust in models are the main barriers.

Data Gaps and Poor Master Data

Bad inputs give bad outputs. Material data and supplier disclosures are often incomplete or inconsistent, which weakens model recommendations. Invest in master data clean-up first.

Supplier Resistance and Capability Gaps

Many tier-two suppliers can’t prove claims. Small suppliers often lack sustainability tracking. You’ll need to offer training, phased requirements, or commercial incentives.

Internal Misalignment

Cost and engineering priorities can clash with sustainability goals. Create simple shared KPIs so stakeholders judge trade-offs the same way. Tie a portion of category manager compensation to agreed metrics.

Model Explainability and Trust

Black-box outputs stall adoption. Provide decision traceability, show comparable alternatives, and let stakeholders inspect the data that drove a recommendation.

Regulatory Fragmentation

Multiple geographies mean different rules. Map requirements and build policy layers so automated checks reflect local law and corporate policy.

Upfront Cost and Skills Gap

Building capabilities requires money and new skills. Balance internal hires and vendor partnerships; buy core models when useful and build custom layers where you need differentiation.

Expect barriers but treat them as solvable risks. Address data first, bring suppliers along, and invest in explainability so adoption scales.

Summary

AI in green procurement makes sustainable sourcing measurable and operational when you combine pilots, governance, and supplier engagement. Applied correctly, AI reduces risk, lowers lifecycle impact, and keeps costs competitive by surfacing smarter alternatives and automating routine tasks.

Success is iterative. Implement pragmatically and scale with governance. Start with one measurable pilot and book a cross-functional alignment session for the quarter. That gives you a chance to prove ROI and position your team as the driver of sustainable value in the green procurement of the electronics industry.

Meet your toughest ESG goals with GEP GREEN. It’s AI-powered, CDP-aligned, and built for net-zero performance.